Sealed electric connector with silicon-aluminum alloy shell and manufacturing method of sealed electric connector

An electrical connector, silicon-aluminum alloy technology, applied in the field of sealed electrical connectors and their manufacturing, can solve problems such as sealing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

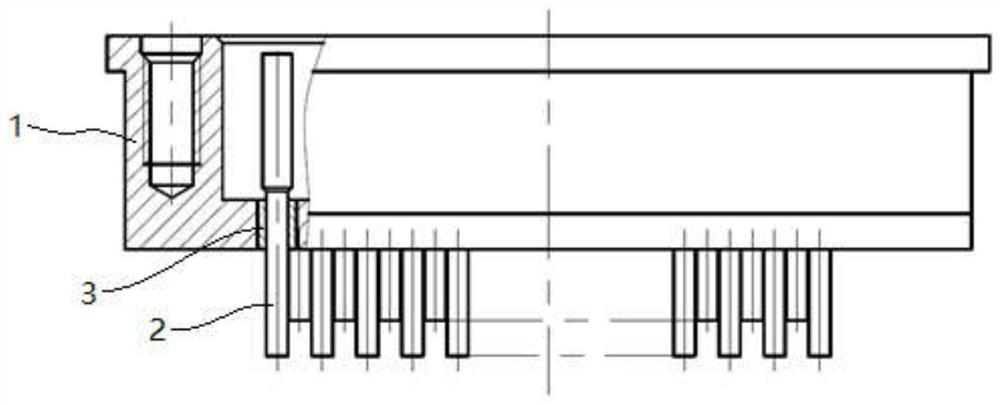

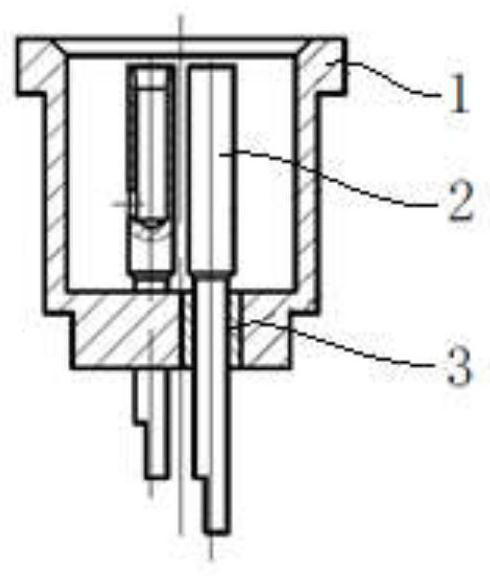

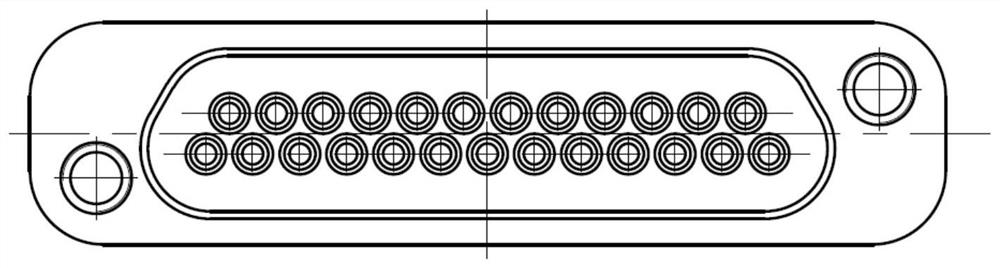

[0038] Such as Figure 1 to Figure 3 As shown, a sealed electrical connector with a silicon-aluminum alloy shell includes a shell 1 and a contact piece 2. A number of sealing holes are opened in the shell 1, and the middle part of the contact piece 2 is fixed in the sealing hole through a glass insulator 3, and Both ends of the contact piece 2 protrude from the sealing hole, and the exposed surface of the glass insulator 3 is covered with high-temperature glue to avoid the residue of organic solvents such as plating solution or flux.

[0039] The material of the shell 1 is silicon-aluminum alloy with a silicon content of 40% to 60%, the material of the contact piece 2 is low-carbon steel or 4J50, the grade of low-carbon steel is 10# steel, 20# steel or 45# steel, glass The material of the insulator 3 is selected from bismuth-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com