Motorcycle engine right bent axle box

A crankcase and right crankcase technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of product weight, large product wall thickness, and unreasonable design, so as to reduce production costs and improve work Efficiency, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

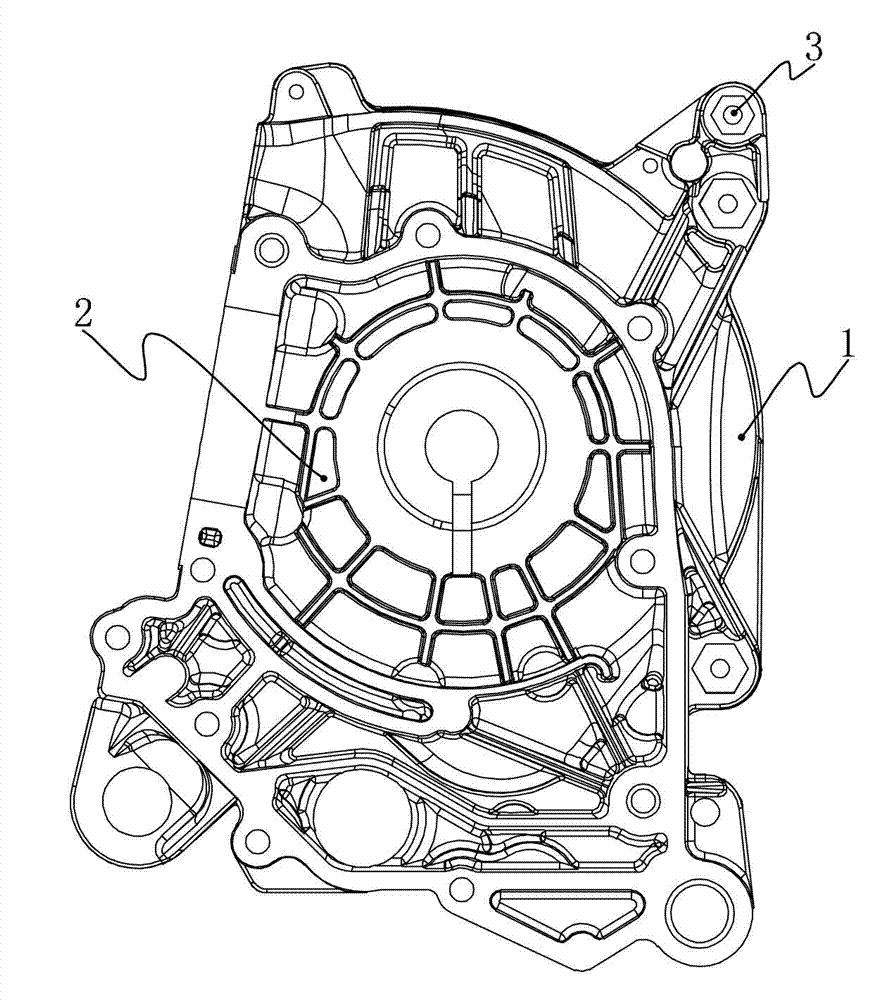

[0009] Such as figure 1 As shown, the present invention provides the right crankcase of motorcycle engine, comprises box body 1, and box body 1 is connected with motorcycle engine right crankcase cover, and box body 1 is aluminum alloy die-casting, and the wall of box body 1 The thickness is 4 mm, the side of the box body 1 is provided with reinforcing ribs 2 , and the box body 1 is provided with fastening screw holes 3 .

[0010] In this embodiment, the box body 1 is an aluminum alloy die-casting, the material used is aluminum alloy, and its density is 2.7g / cm 3 , while the density of cast iron is 7.8g / cm 3 , In this way, the weight of die-casting products is only about 34.6% of the weight of existing casting products, which can meet the development needs of light weight. In fact, the wall thickness of the die-casting product is only 4mm, while the wall thickness of the original casting product is 6mm, which provides good conditions for the design of the fastening screw hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com