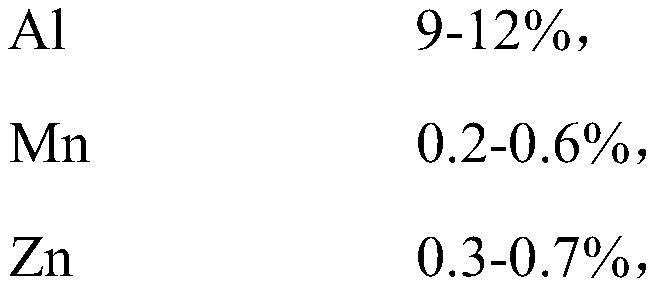

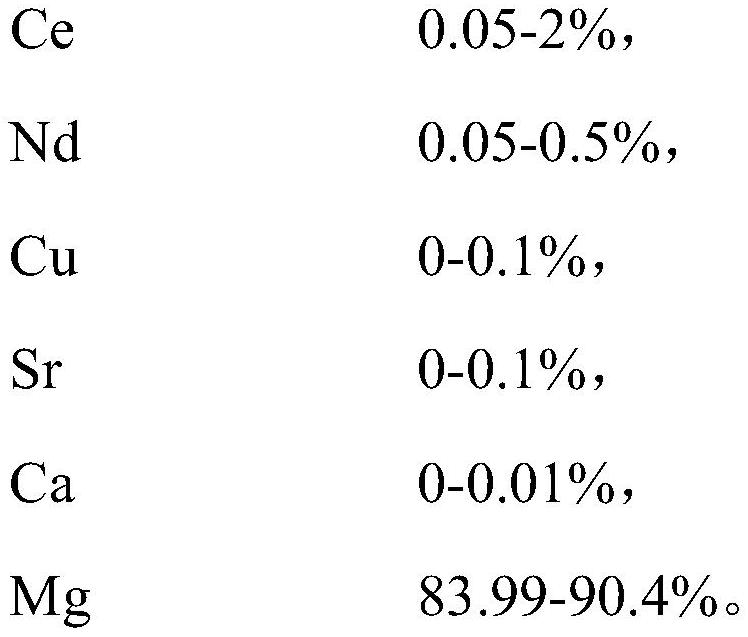

A kind of magnesium alloy and its preparation method and application

A technology of magnesium alloy and high content, which is applied in the field of alloys and can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

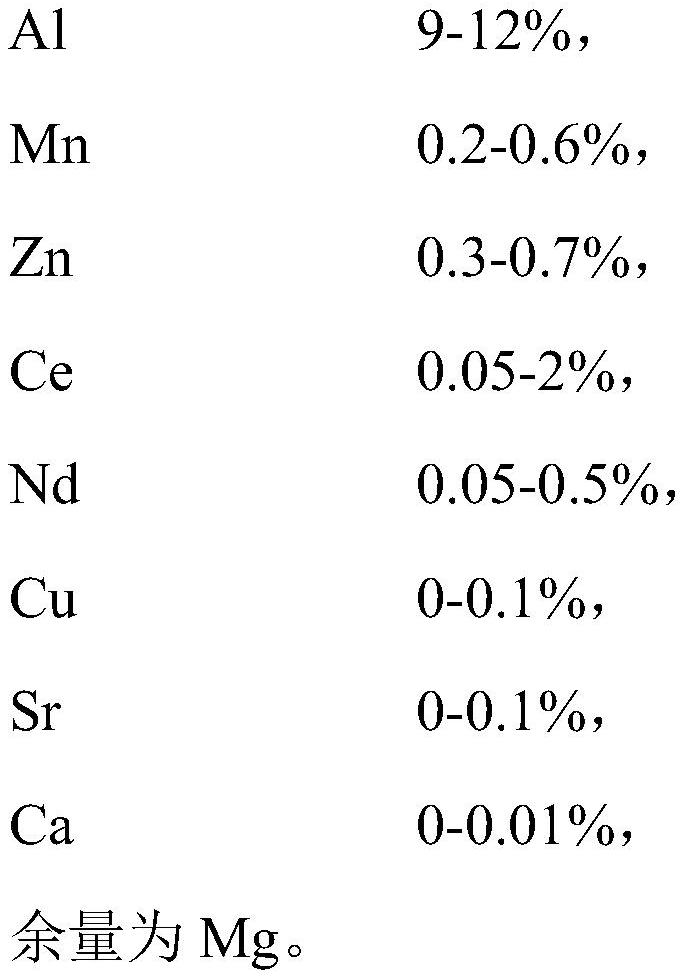

Embodiment 1

[0038] Alloy raw materials were prepared according to the composition of the magnesium alloy shown in Table 1 (based on the total amount of the magnesium alloy, in weight percentage, and the balance being Mg). Put the prepared alloy raw material in a melting furnace for melting, feed 99.99% high-purity argon gas into the melting process, and smelt at a temperature of 720° C. for 30 minutes. The obtained melt is poured into a metal mold, and after cooling, a magnesium alloy casting is obtained.

[0039] The prepared magnesium alloy casting was subjected to aging treatment at 200° C. for 5 hours. After the aging treatment is completed, it is naturally cooled to room temperature.

Embodiment 2-3

[0041] The magnesium alloy was prepared by the same method as in Example 1, except that the alloy raw materials were prepared according to the composition of the magnesium alloy given in Table 1. Wherein, the magnesium alloy casting prepared in Example 2 was subjected to aging treatment at 120° C. for 36 hours, and the magnesium alloy casting prepared in Example 3 was subjected to aging treatment at 350° C. for 6 hours.

Embodiment 4

[0043]The magnesium alloy was prepared by the same method as in Example 1, except that the contents of Ce and Nd were 0.25% and 0.3% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com