High temperature resistance testing device for glass panel of integrated cooker

A glass panel and testing device technology, which is applied in the direction of measuring device, testing material strength by applying repetitive force/pulsation force, and transmittance measurement, etc., can solve the function loss of integrated stove, the glass panel is not strong in high temperature resistance, and cannot be clearly reflected Integrated stove and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

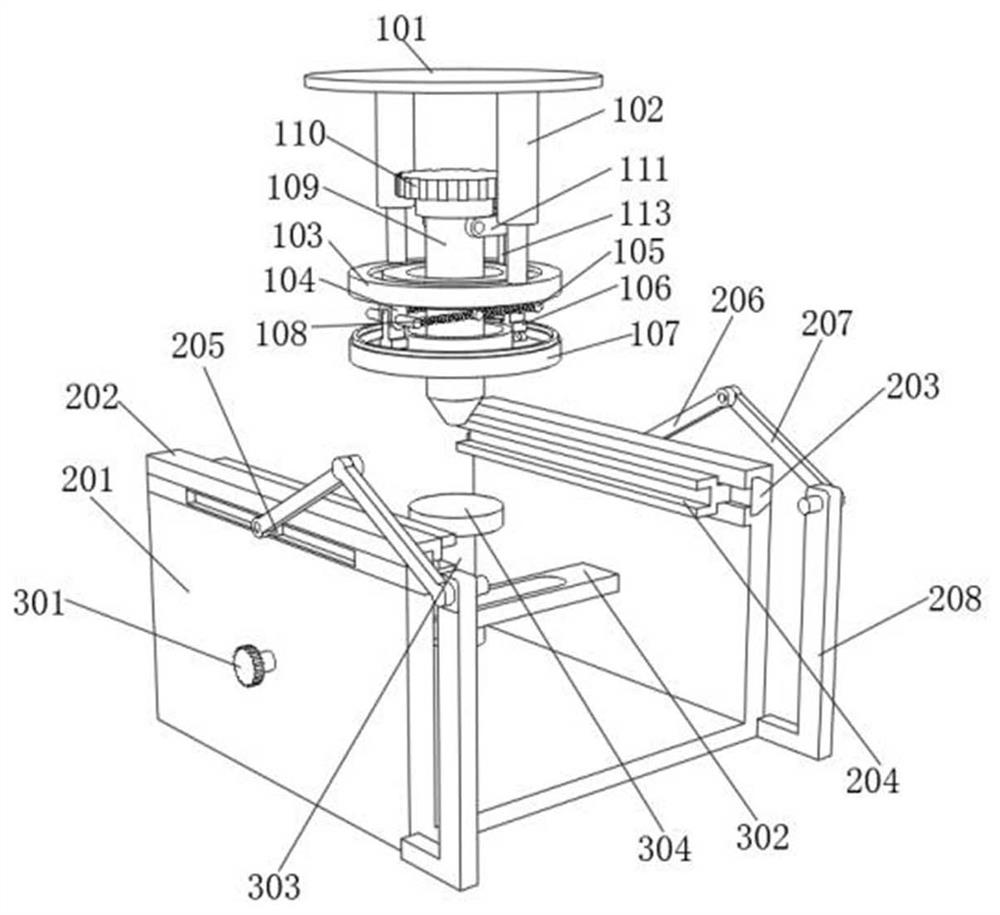

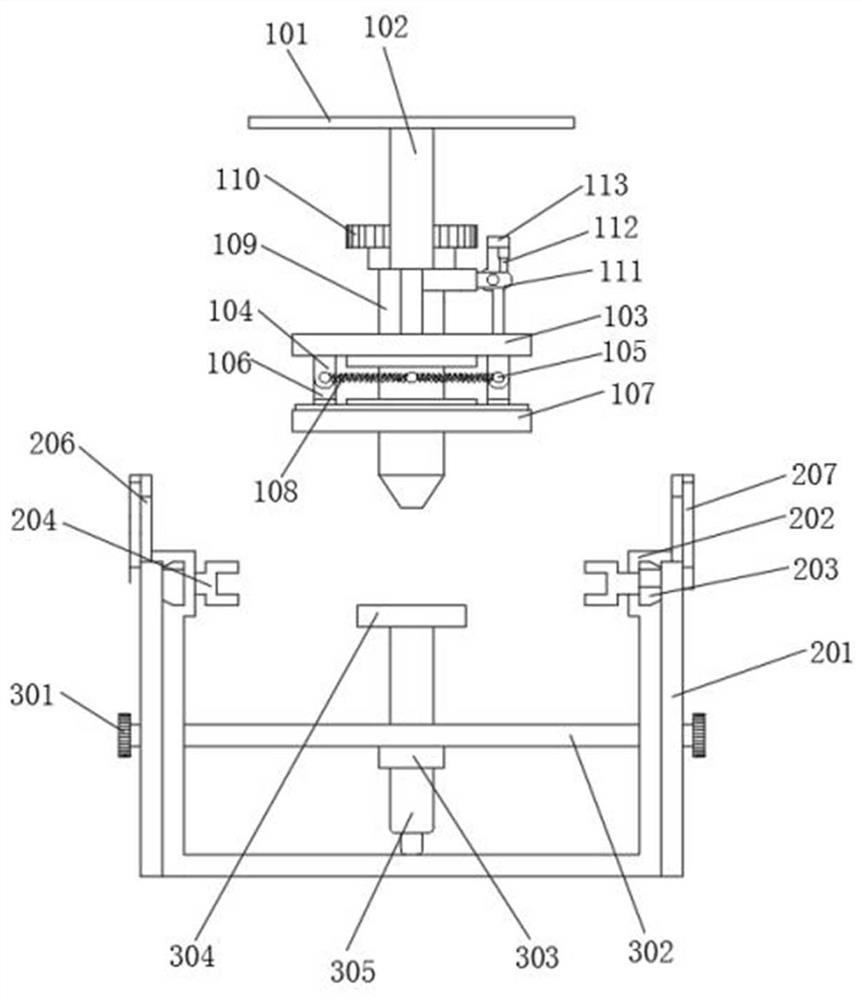

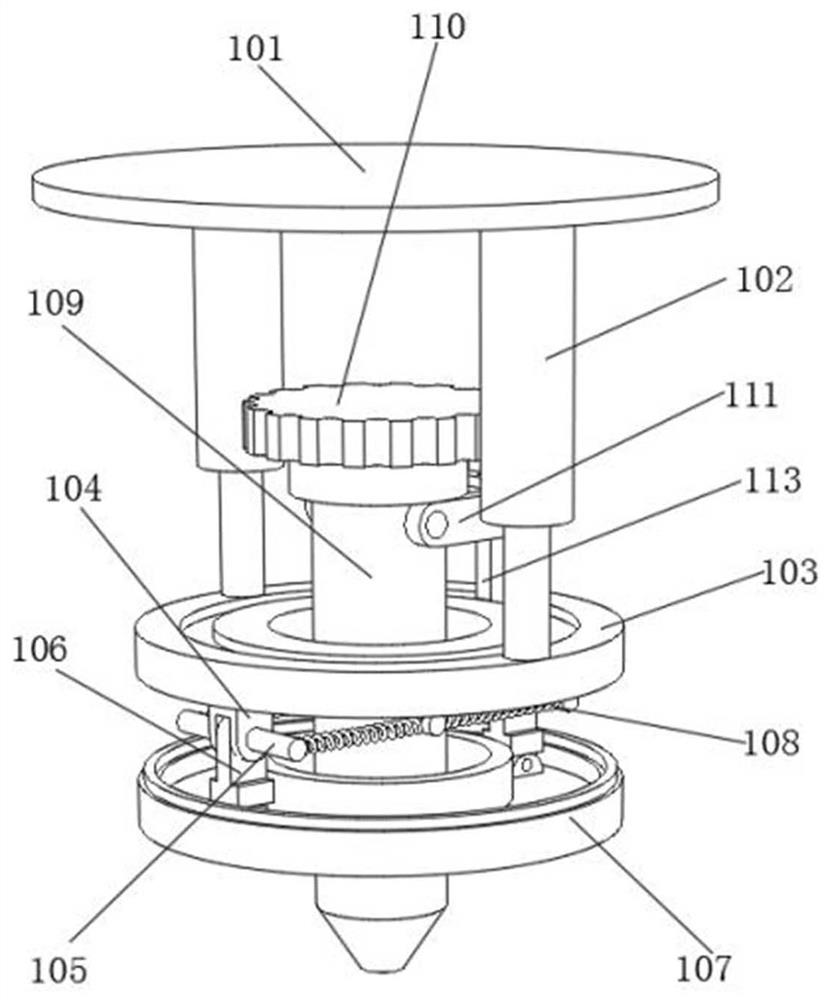

[0035] see Figure 1 to Figure 6 , a high temperature resistance test device for an integrated stove glass panel, comprising a top plate 101, the top plate 101 defines the position of the telescopic rod 102, two telescopic rods 102 are fixedly connected below the top plate 101, the size of the telescopic rod 102 is the same as that of the top plate 101 to the top plate 103 The distances between the two telescopic rods 102 are matched, and the two telescopic rods 102 are axially symmetrically distributed with the follower 302 as the axis of symmetry. The telescopic rods 102 rise or fall, which can drive other structures such as the top plate 103, the chassis 107 and the rotating column 109. contact with the glass panel to test the impact resistance of the glass panel;

[0036] A top plate 103 is fixedly connected to one end of the two telescopic rods 102 away from the top plate 101 , the top plate 103 is provided with an annular groove whose size matches the bottom of the limit...

Embodiment 2

[0045] see Figure 7 to Figure 10 , a high temperature resistance test device for an integrated stove glass panel, including a frame 201, the frame 201 defines the positions of the trapezoidal block 203 and the follower 302 and other structures; the frame 201 is provided above with two limiting blocks 202, the limiting blocks 202 and the A through hole with a size matching the trapezoidal block 203 is formed between the frames 201, and the limiting block 202 defines the position of the trapezoidal block 203;

[0046] Two opposite trapezoidal blocks 203 are arranged below the two limiting blocks 202. The trapezoidal block 203 is provided with a groove whose size matches the sliding block 205 on the side close to the connecting rod 1 206. The trapezoidal block 203 connects the clamping block 204 and the sliding block. 205. When the trapezoidal block 203 starts to move under the action of the sliding block 205, the position of the clamping block 204 is changed; The opposite side...

Embodiment 3

[0050] see Figure 7 to Figure 10 , a high-temperature resistance test device for an integrated stove glass panel, including a runner 301, and the position of the follower 302 can be adjusted by rotating the runner 301; A through hole with a size matching the connection block 303 is opened, the size of the follower 302 is matched with the frame 201, and the follower 302 is deflected under the driving of the runner 301, thereby changing the position of the heating plate 304 and the spotlight 305;

[0051] The inside of the follower 302 is provided with a connecting block 303. The size of the connecting block 303 matches the through hole opened in the follower 302. The two ends of the follower 302 are hinged to the two sides of the frame 201 respectively. The position of the heating plate 304 and the spotlight 305; the heating plate 304 is fixedly connected to the top of the connection block 303, and the heating plate 304 contacts the glass panel when it continues to heat up, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com