Wearing resisting process experiment device for conductive fiber

A technology of conductive fiber and experimental device, applied in the direction of measuring device, testing wear resistance, instrument, etc., can solve the problems of inability to record, the wear resistance of conductive fiber cannot be clearly characterized, etc., and achieve the effect of simple device and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific implementation of the conductive and wear-resistant process test is carried out with carbon black coated nylon conductive fiber monofilament as the test sample.

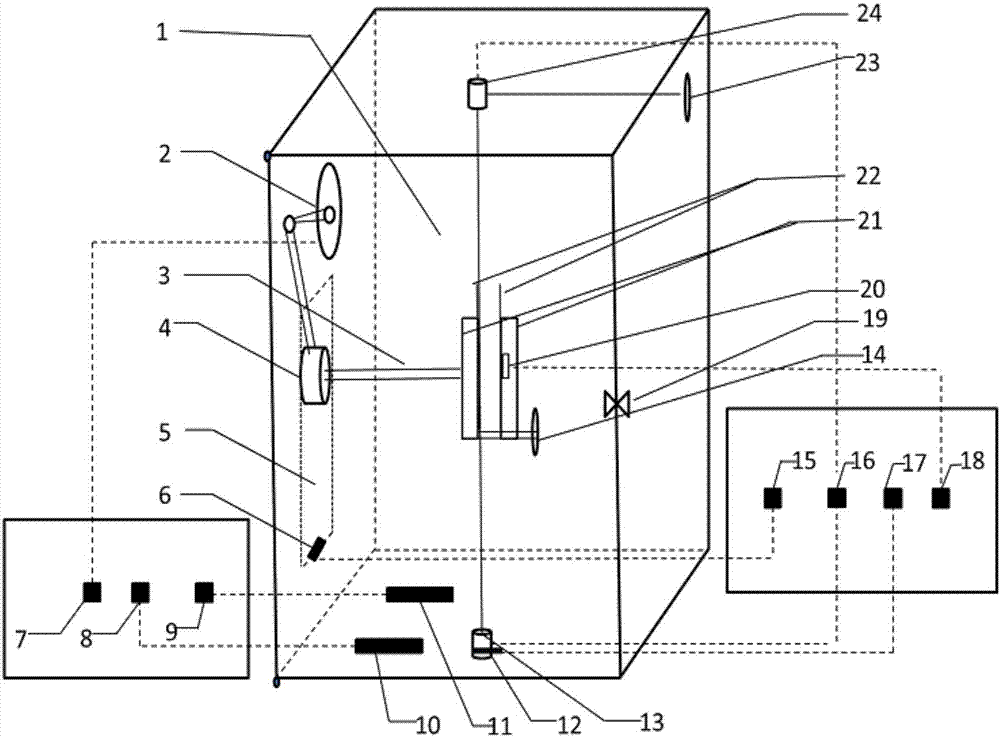

[0029] Select carbon black-coated nylon conductive fiber monofilament as the test fiber, select the tension at both ends of the fiber to be tested as 5N, the speed of the eccentric motor as 30 rpm, the pressure between the friction plates as 5N, and the built-in temperature as 50°C , relative humidity is 30%RH. The conductive wear resistance testing device of conductive fiber in embodiment 1 is adopted to carry out the conductive wear resistance test of carbon black coated nylon conductive fiber monofilament:

[0030] During use, the lower end of the conductive fiber to be tested is fixed with the sample fixing part 12, and then the upper end of the fiber is fixed, and the tension at both ends of the fiber is adjusted to 5N by adjusting the upper fixing part 23, and the pressure between the fricti...

Embodiment 2

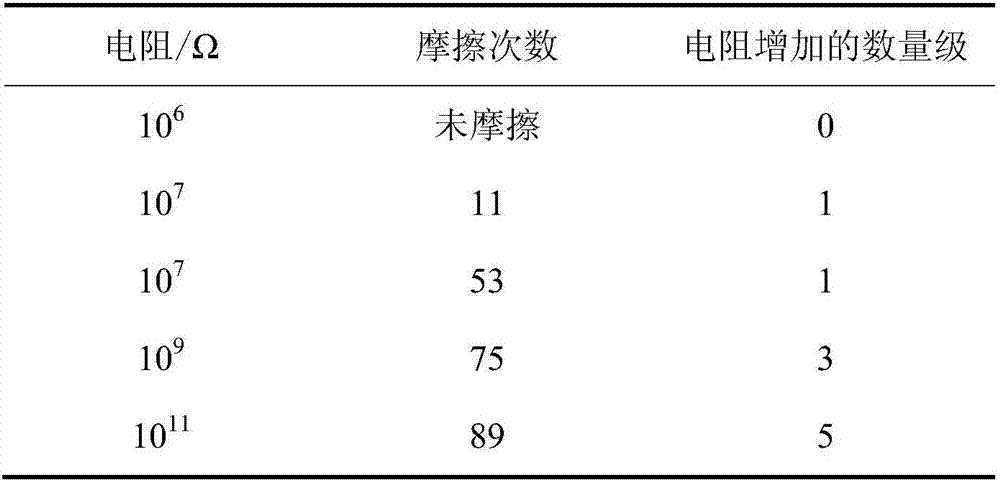

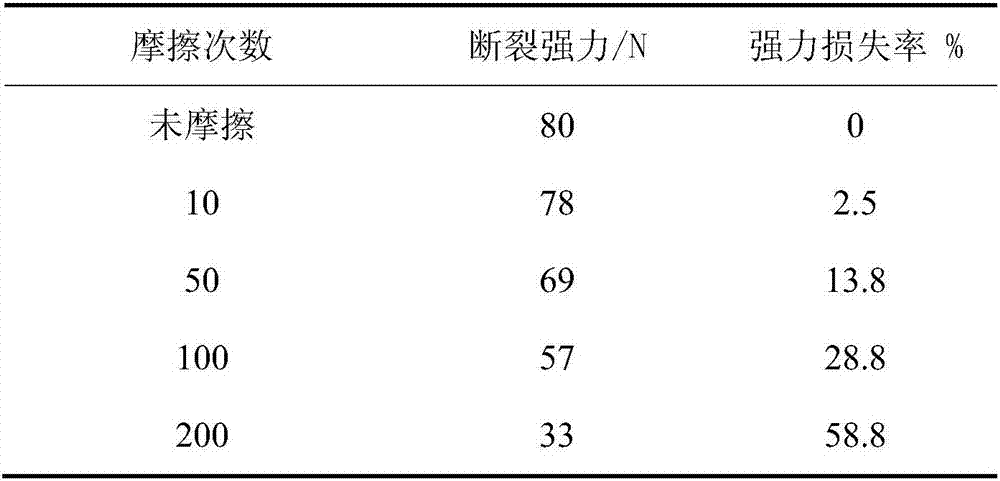

[0039] The carbon black-coated nylon conductive fiber monofilament in Example 1 was used as the test sample, and subjected to different times of rubbing to perform a mechanical performance test, and the test results are shown in Table 2.

[0040] Table 2 Test results of mechanical properties of fibers under different friction times

[0041]

Embodiment 3

[0043] Adopt the step in embodiment 1 to carry out conductive wear-resisting process test to polyaniline coated type polyester fiber monofilament:

[0044] The first step is to take 20 polyaniline-coated polyester fiber monofilaments, select a monofilament sample from them, fix the lower end of the conductive fiber to be tested with the sample clamping part 12, and then fix the upper end of the fiber, and adjust it up and down. The upper end clamping part 23 is used to adjust the tension at the two ends of the fiber to be 10N;

[0045] The second step is to adjust the pressure between the friction plates 22 to stop the adjustment when it reaches the set pressure value of 5N;

[0046]The third step is to wait for the temperature and humidity of the internal environment to reach 25°C and 30% RH respectively, then start the eccentric wheel motor 2 to make the eccentric wheel move at the set speed of 30 rpm, driving the friction plate to reciprocate ;

[0047] The 4th step, obse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com