Fault detection for iterative learning control of time-varying systems

An iterative learning control and fault detection technology, which is applied in manufacturing tools, measuring devices, material defect testing, etc., and can solve problems such as poor performance conservative learning algorithms and unstable ILC algorithms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

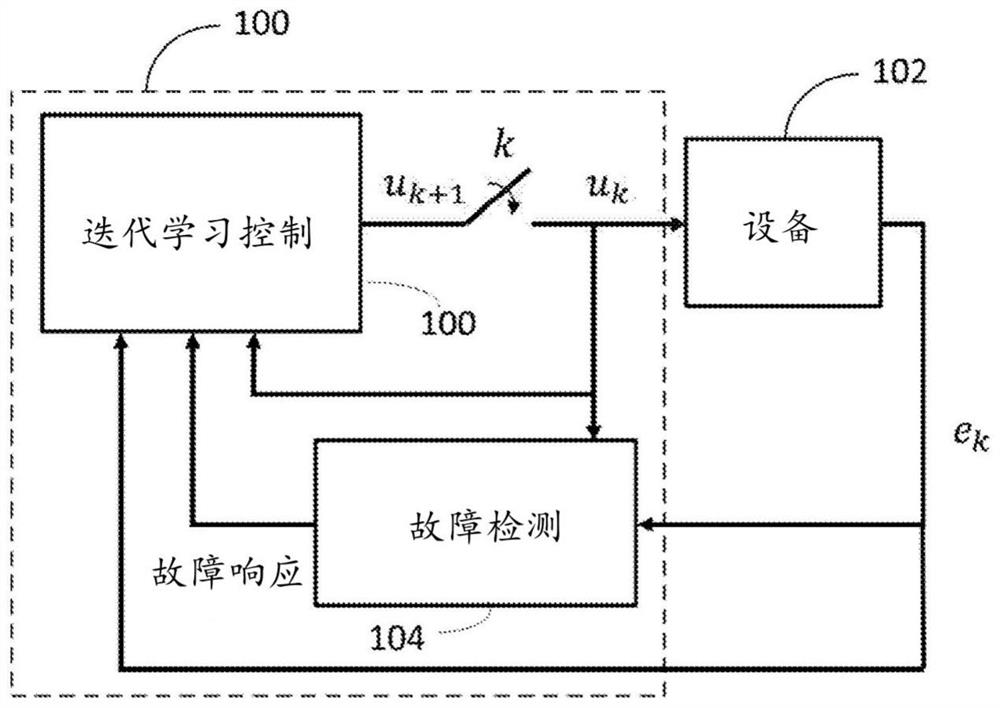

[0025] refer to figure 1 , the ILC controller 100 controls the device 102 according to an aspect of the present invention. Device 102 may include a potentially non-repetitive system. The ILC controller 100 includes an ILC algorithm 106 and a fault detection algorithm 104 . The fault detection algorithm 104 detects when the ILC algorithm 106 applied to the device 102 either 1) violates assumptions for guaranteeing asymptotic stability or 2) fails to meet predefined performance specifications or both. If operating conduction or stability requirements are not met, the fault detection algorithm 104 generates a fault detection signal indicative of a fault condition.

[0026] Assuming U and Y are Banach spaces with suitable norm, use || · || to denote the vector and induced operator norm in the appropriate space. In some embodiments, the class of ILC systems includes linear time-invariant systems of the form:

[0027]

[0028] where y k ∈ Y is the output signal, u k ∈U is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com