Hollow nose prosthesis

An integrated, nose technology, applied in the field of nasal prosthesis, can solve the problem that the nose cannot be kept soft for a long time, and achieve the effect of avoiding the redness and hardening of the nose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

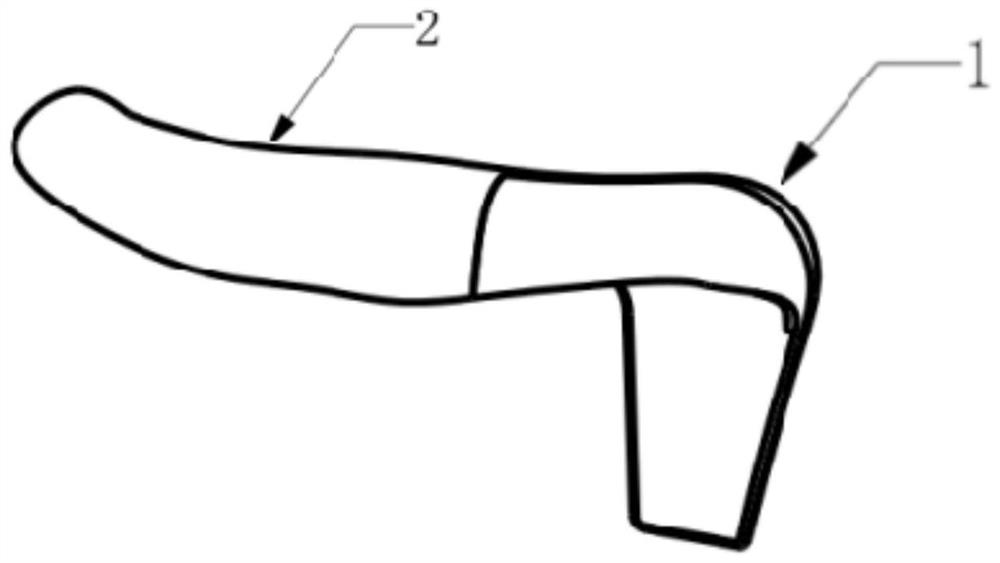

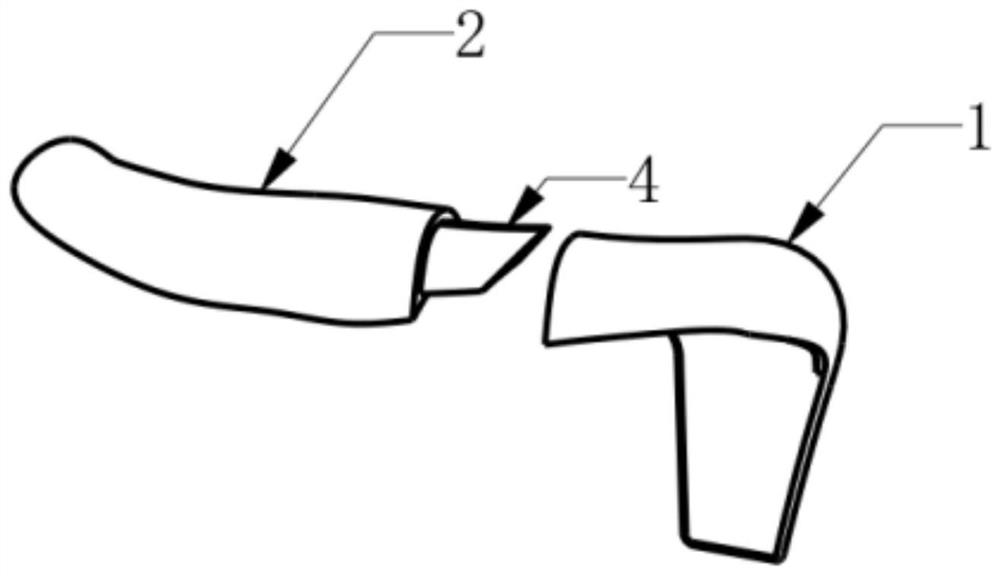

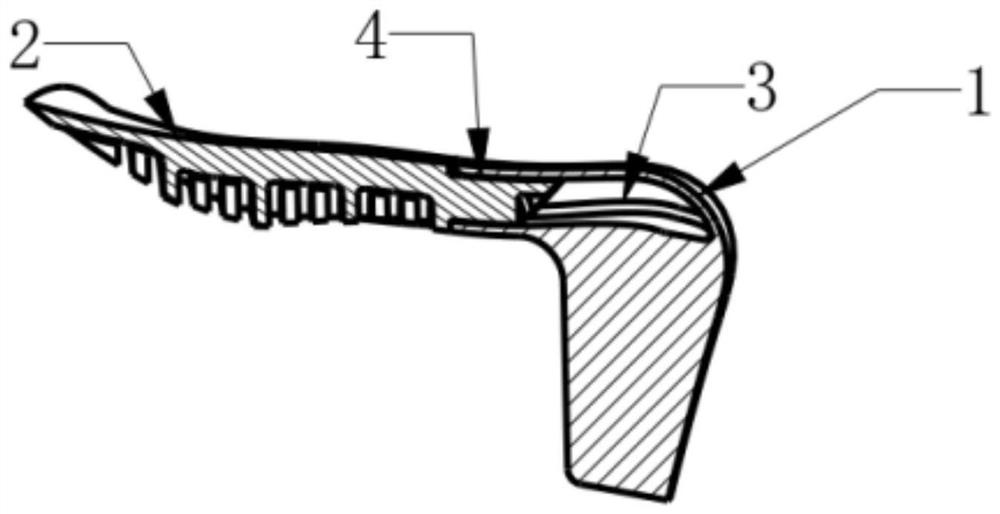

[0038] like Figure 1 to Figure 4 As shown, what is prepared in this example is a silicone rubber nose implant, which includes a nose head 1 and a nose back 2, and the nose head 1 and the nose back 2 are respectively molded; wherein, the nose back 2 is provided with a connecting part 4, which is a protruding structure; the nose head 1 is also provided with a connecting part, which is a concave structure for insertion of the connecting part 4 of the back of the nose 2; The connecting part of the nose part 1 and the connecting part 4 of the nasal dorsum 2 can be connected to each other and cooperate closely, so that the nasal head part 1 and the nasal dorsal part 2 are integrated to form a nasal implant.

[0039] The joined nasal implant forms at least one cavity 3 in the nasal head 1, which is encased in the material of the nasal implant, wherein the cavity 3 is formed by moulding The complete structure formed separately in the nose head 1 .

[0040] The nasal dorsum 2 includ...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, except that:

[0044] A complete cavity 3 is not formed in the nasal head 1; by inserting the connecting part 4 of the nasal dorsum 2 into the connecting part of the nasal head 1, the two connecting parts are tightly fitted to form a complete cavity in the nasal head 1 cavity structure.

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 1, except that:

[0047] The nasal head 1 and the nasal back 2 are packaged separately, and they are connected together during the operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com