Nose implant manufacturing method

A kind of system and prosthesis technology, applied in the direction of prosthesis, prosthesis, additive manufacturing, etc., can solve the problems of position deformation, not easy to make, long time, etc., and achieve the effect of reducing inflammation and shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific matters of the embodiment are included in the detailed description and the drawings.

[0040] Advantages and features of the present invention and methods for realizing them can be clearly understood with reference to the accompanying drawings and the embodiments described in detail later. However, the present invention is not limited to the embodiments disclosed below, and can be implemented in various forms. This embodiment is provided only to fully disclose the present invention and fully inform those skilled in the art of the scope of the invention, and the present invention should be defined by the scope of the claims. Furthermore, the same reference numerals are used for similar parts throughout the specification.

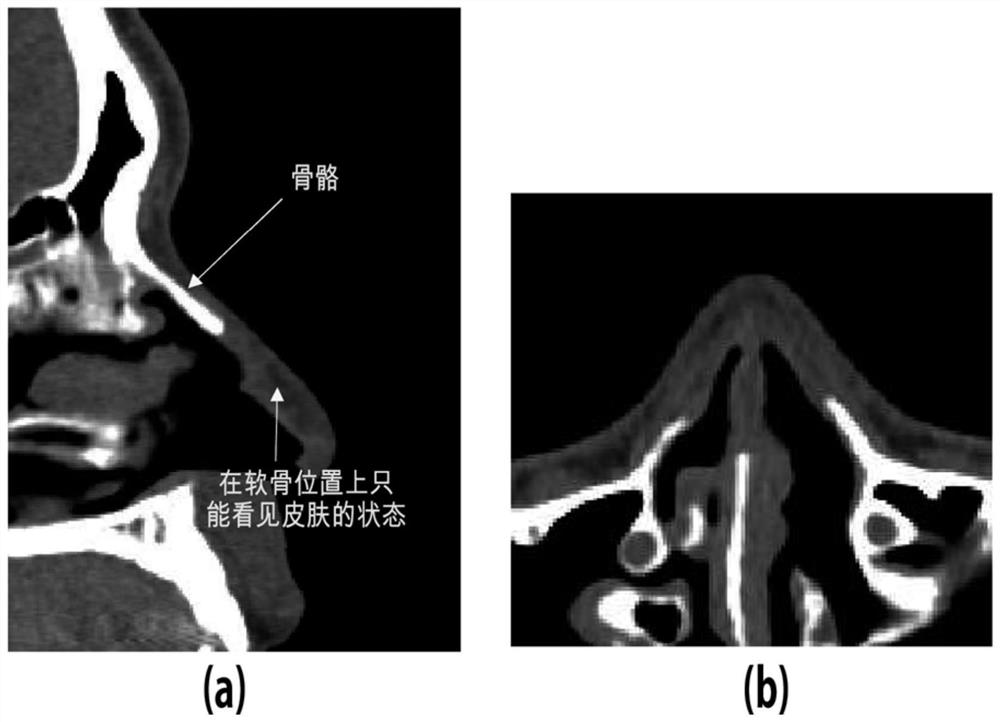

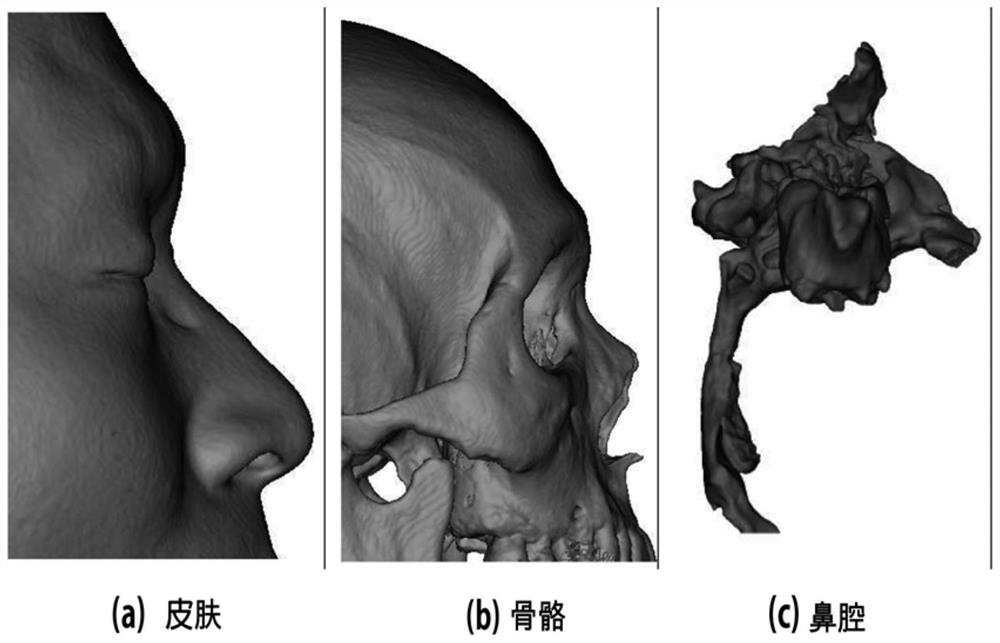

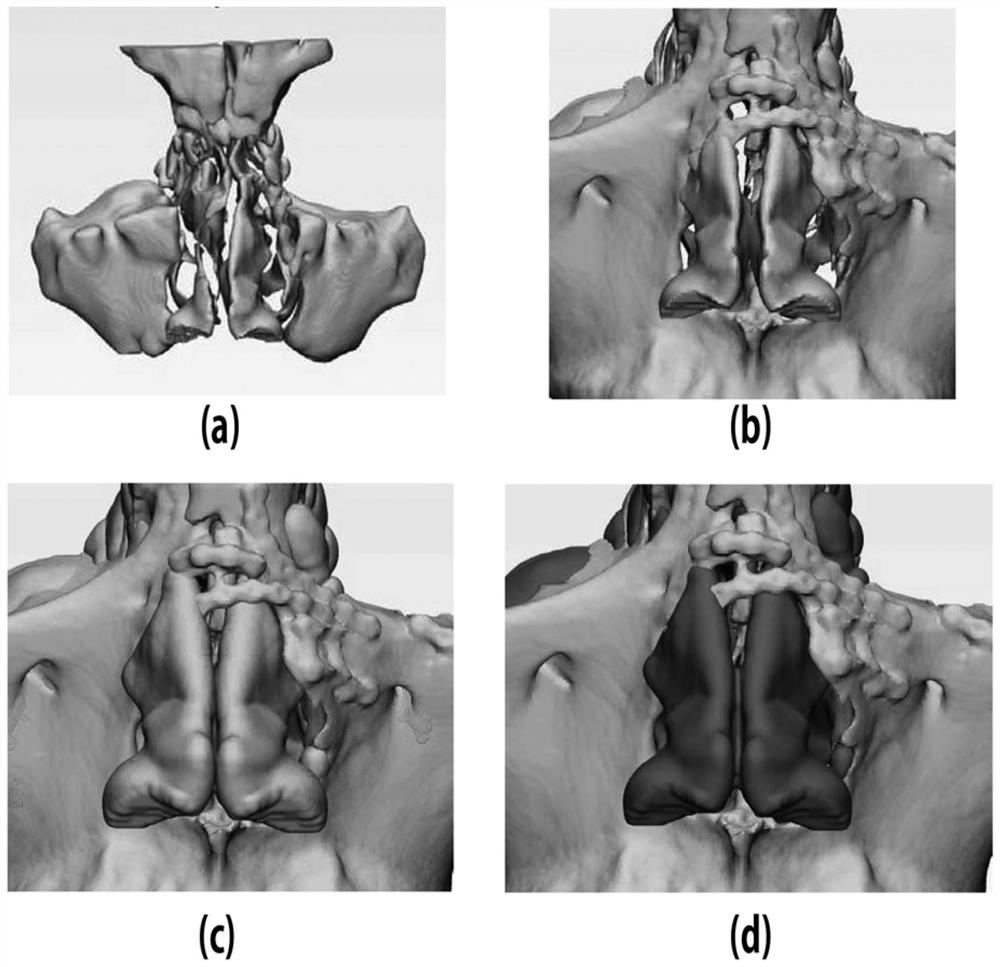

[0041] Hereinafter, the present invention will be described through the embodiments of the present invention and with reference to the accompanying drawings for explaining the method of manufacturing a nasal prosthesis.

[0042] The nasa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com