70MPa high-flow hydrogenation system

A hydrogenation system and large flow technology, applied in the field of hydrogenation stations, can solve the problems of small inner diameter of the hose, inability to select a safe and reliable large-flow microchannel heat exchanger, and a large inner diameter hose with a less hard design. The effect of overcoming bottlenecks and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

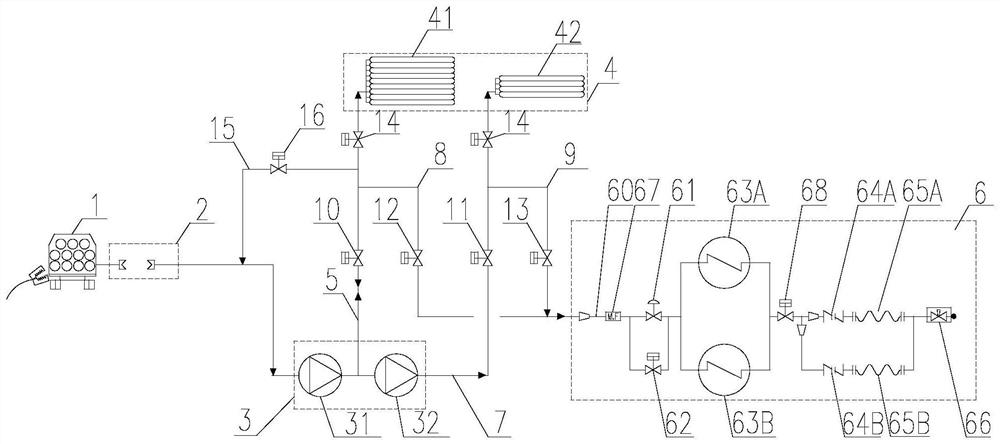

[0032] like figure 1 As shown, the present invention is a 70MPa large-flow hydrogenation system, including a hydrogen source 1, an unloading column 2, a medium and high pressure compressor 3, a hydrogen storage bottle group 4 and a hydrogenation machine 6 connected by pipelines. The engine 6 includes a main pipe 60, and a regulating valve group, a micro-channel heat exchanger group, a hydrogenation hose group and a large-flow hydrogenation gun 66 connected in sequence through the main pipe 60, and the regulating valve group includes a flow regulating valve 61 connected in parallel. and bypass shut-off valve 62, the microchannel heat exchanger group includes at least 2 parallel microchannel heat exchangers 63, the hydrogenation hose group includes at least 2 parallel hydrogenation hoses 65, and each The input end of the hydrogenation hose is provided with a break valve 64, the output end of the medium and high pressure compressor 3 is connected to the hydrogen storage bottle gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com