Piston for IC engine

A technology for internal combustion engines and pistons, which is applied in the field of internal combustion engine pistons, and can solve problems such as reducing the knocking sound of pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now, the present invention will be described by means of embodiments with reference to the accompanying drawings.

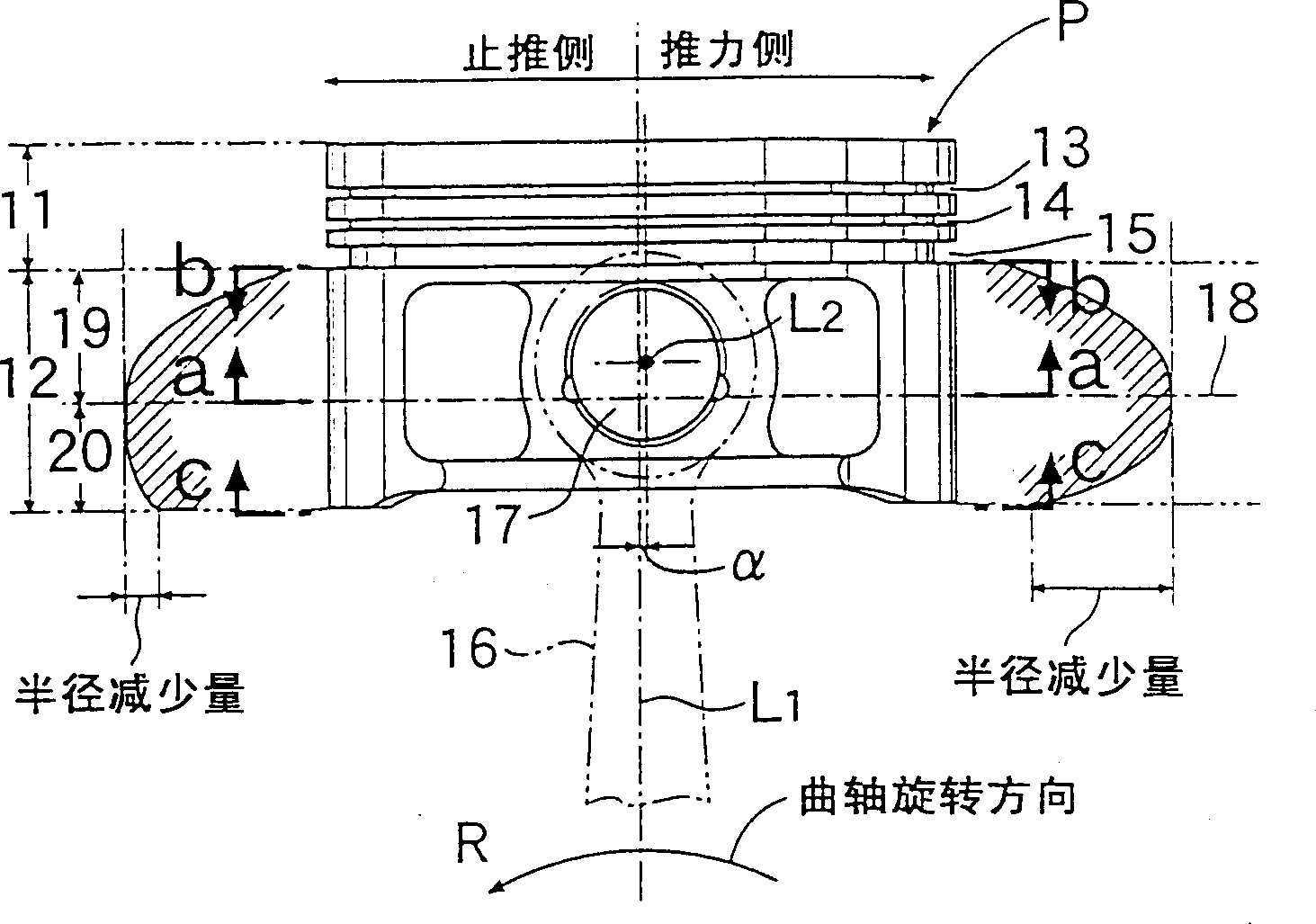

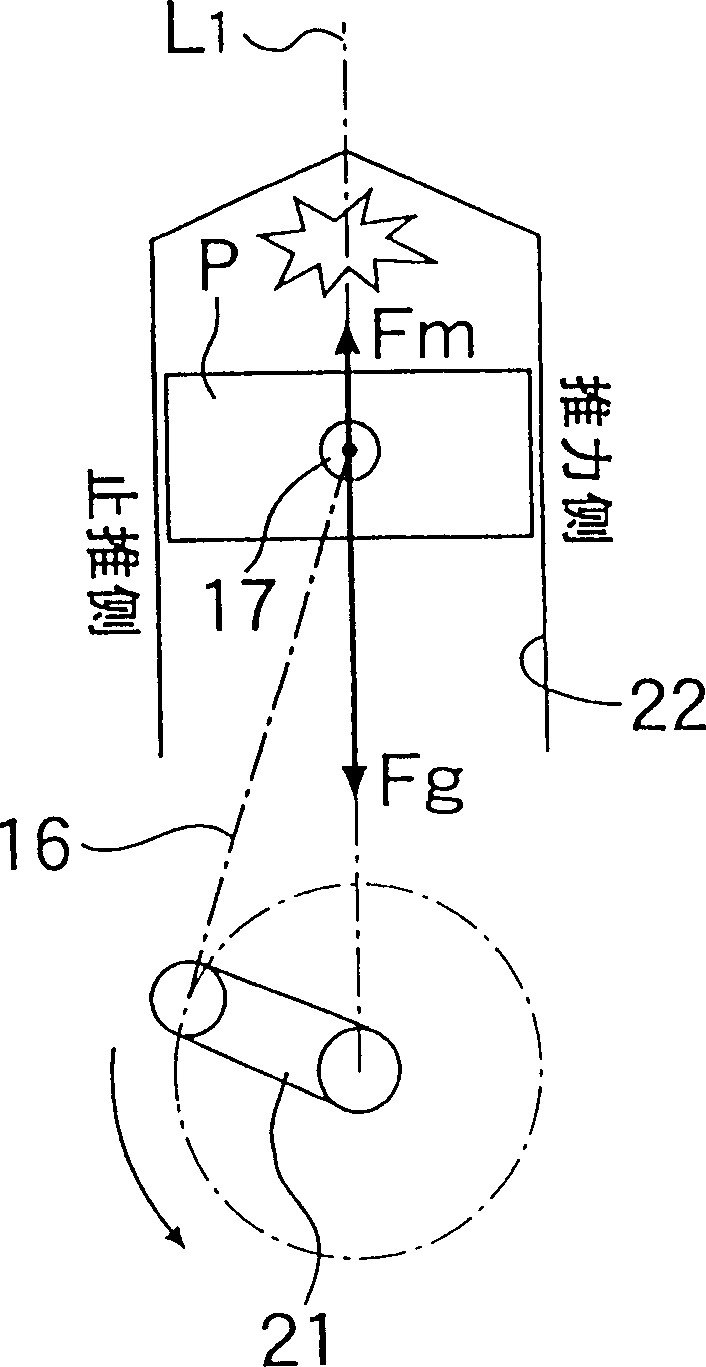

[0029] figure 1 The piston P of the shown 4-stroke cycle internal combustion engine comprises a piston crown 11 facing the combustion chamber and a skirt 12 facing the crankcase. Two compression ring mounting grooves 13 and 14 and an oil ring mounting groove 15 are defined on the piston top 11 . A connecting rod 16 is swingably connected at its small end to the skirt 12 via a piston pin 17 .

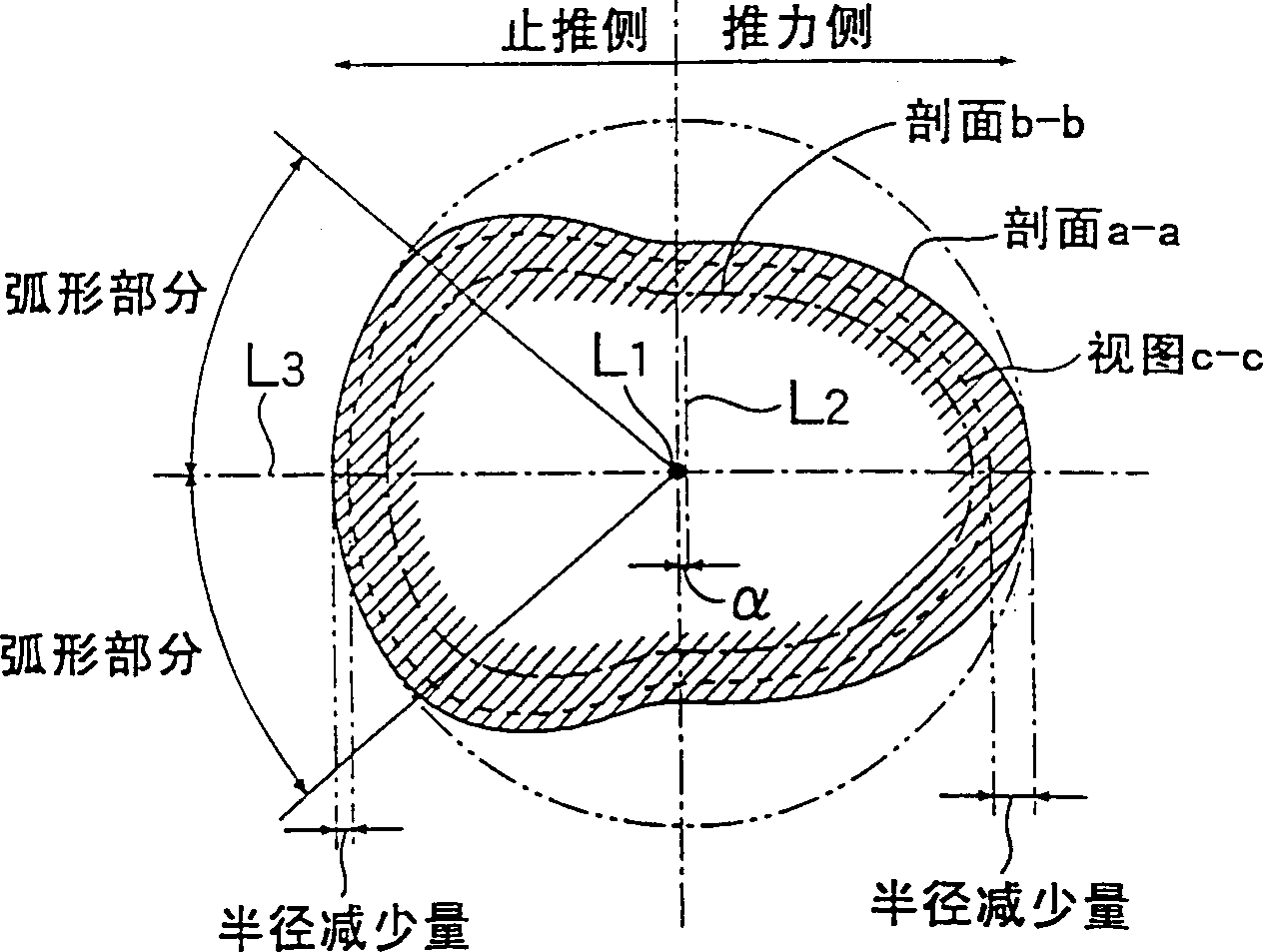

[0030] The cross-sectional shape of the skirt 12 of the piston P is along the cylinder axis L 1 changes continuously in the direction. More specifically, the skirt 12 is at its vertical middle portion (along the cylinder axis L 1 direction) has a maximum diameter portion 18, and the upper skirt 19 and the lower skirt 20 are separated from each other by the maximum diameter portion 18. The largest diameter portion 18 is the portion of the skirt 12 that has the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com