Tubular lamp and mfg. method thereof

A manufacturing method and technology for tubular lamps, which can be applied to incandescent lamps, discharge lamps, discharge tubes, etc., can solve the problems of increased cost, manual operation, and reduced production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

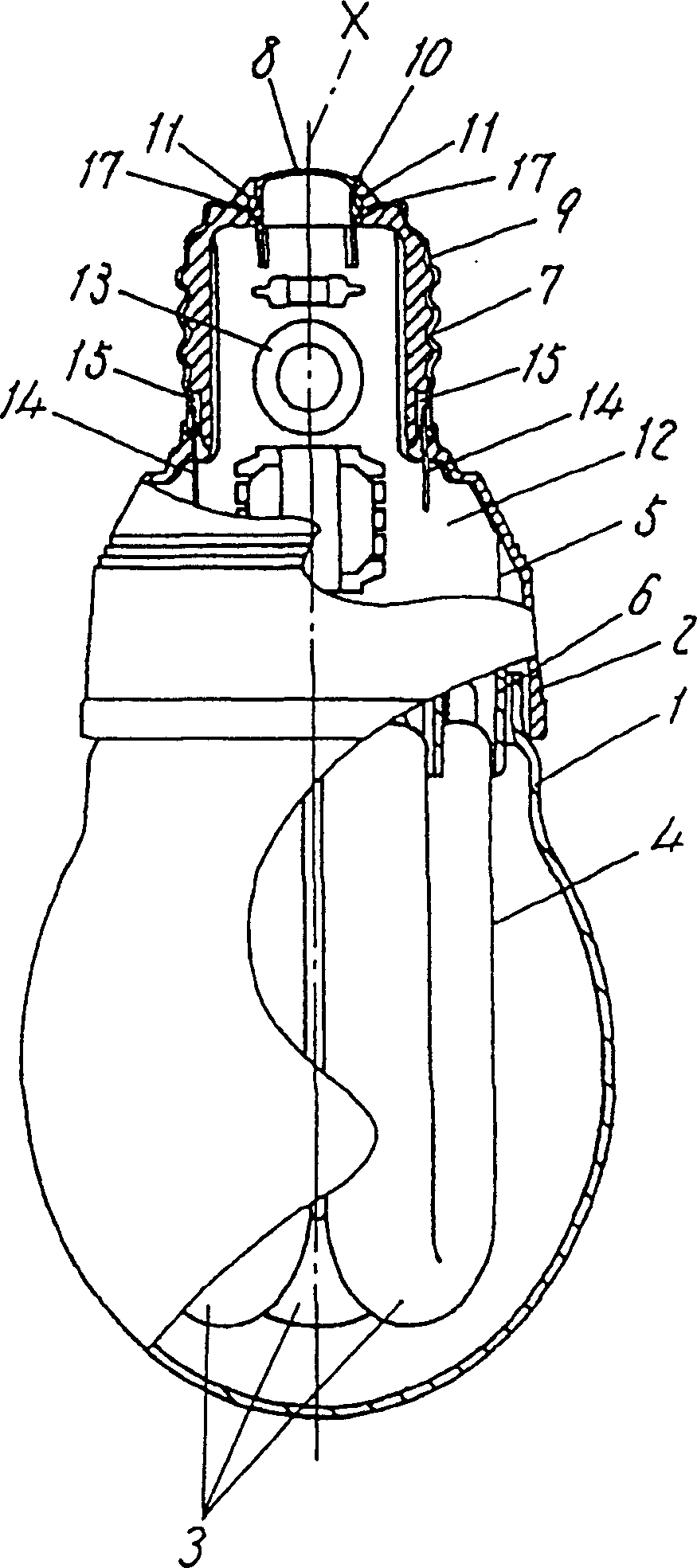

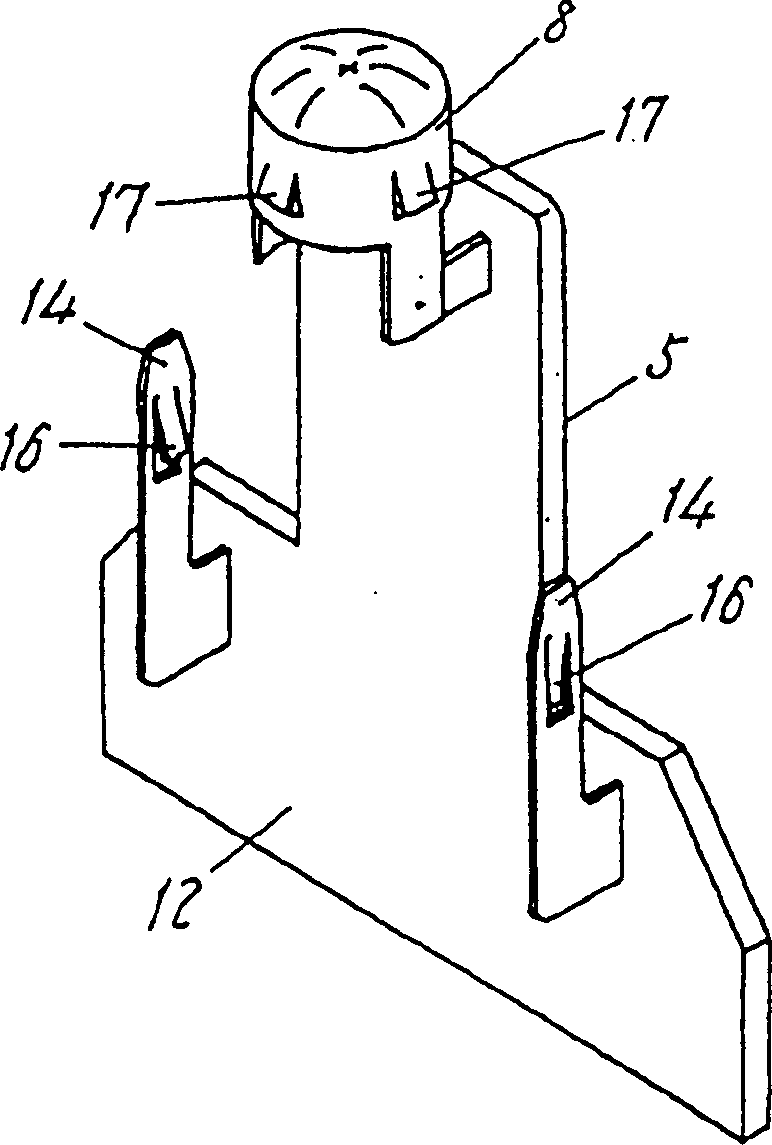

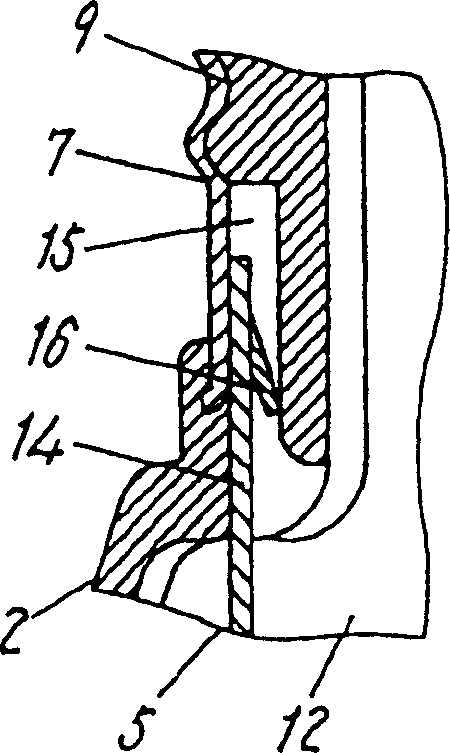

[0027] Embodiments of the present invention will be described below with reference to the drawings.

[0028] The bulb-type fluorescent lamp of the first embodiment of the present invention with a rated power of 13W has an overall length of 120 mm and a maximum outer diameter of 60 mm. Such as figure 1 As shown, in a peripheral device formed by a light-transmitting glass shell 1 and a resin tube shell 2, a fluorescent tube 4, which is bridged by three U-shaped tubes 3 with an outer diameter of 11mm to form a discharge circuit, is installed. A lighting circuit 5 for lighting the tube 4 , and a holder 6 that holds one end of the fluorescent lamp 4 and holds the lighting circuit 5 on the opposite side of the fluorescent tube 4 .

[0029] At one end of the case 2, a socket portion 7 to be inserted into a base (not shown) of a lighting fixture is formed. The socket part 7 has an eyelet 8 and a base 9 which are in electrical contact with the base. Furthermore, an eye socket porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com