Shield support for thick coal layer

A technology for shielding brackets and top coal caving, which is applied to mine roof brackets, mining equipment, earthwork drilling, etc., and can solve problems such as reduced bearing capacity of brackets, unusability, and small height of cut coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

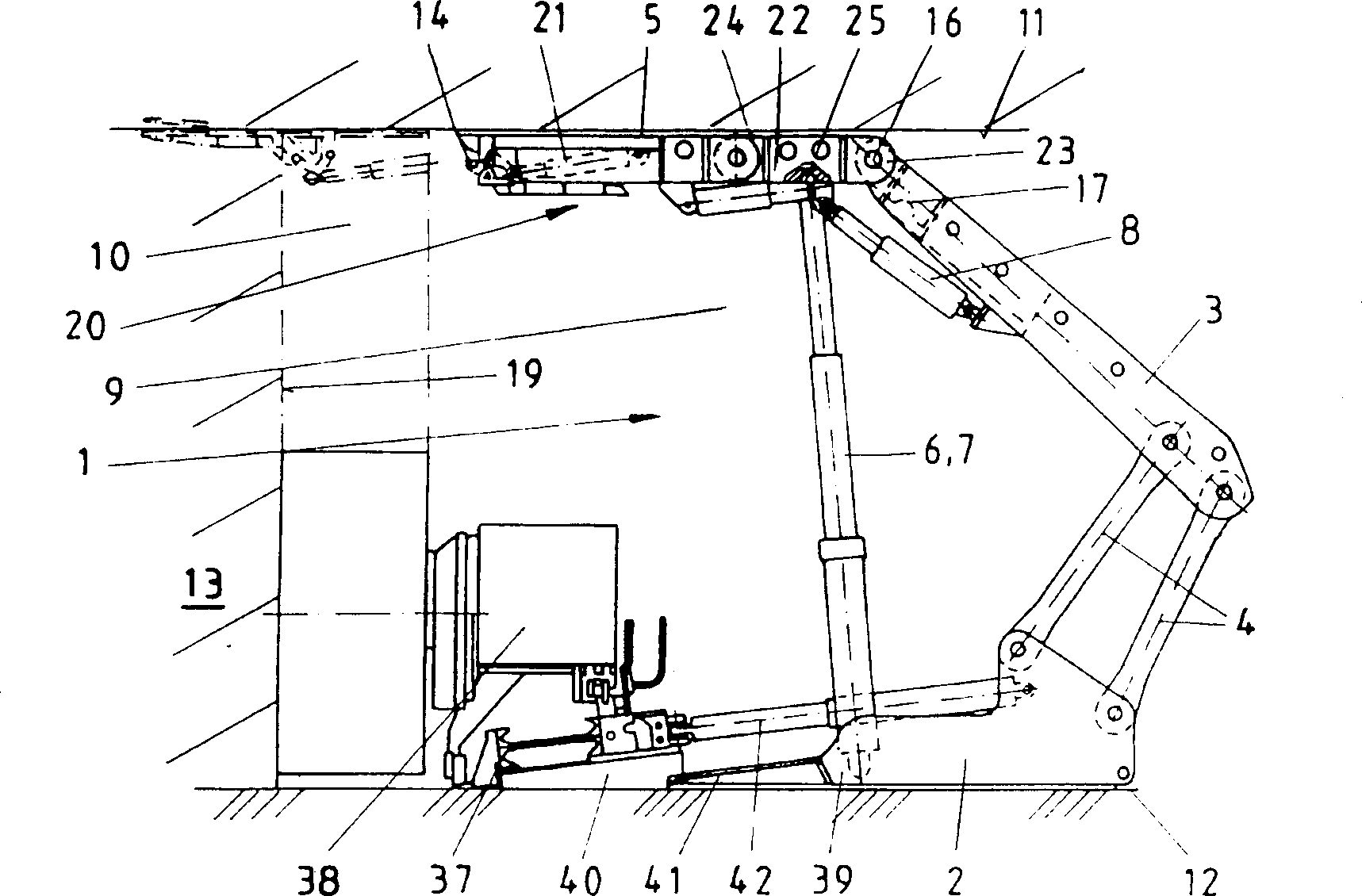

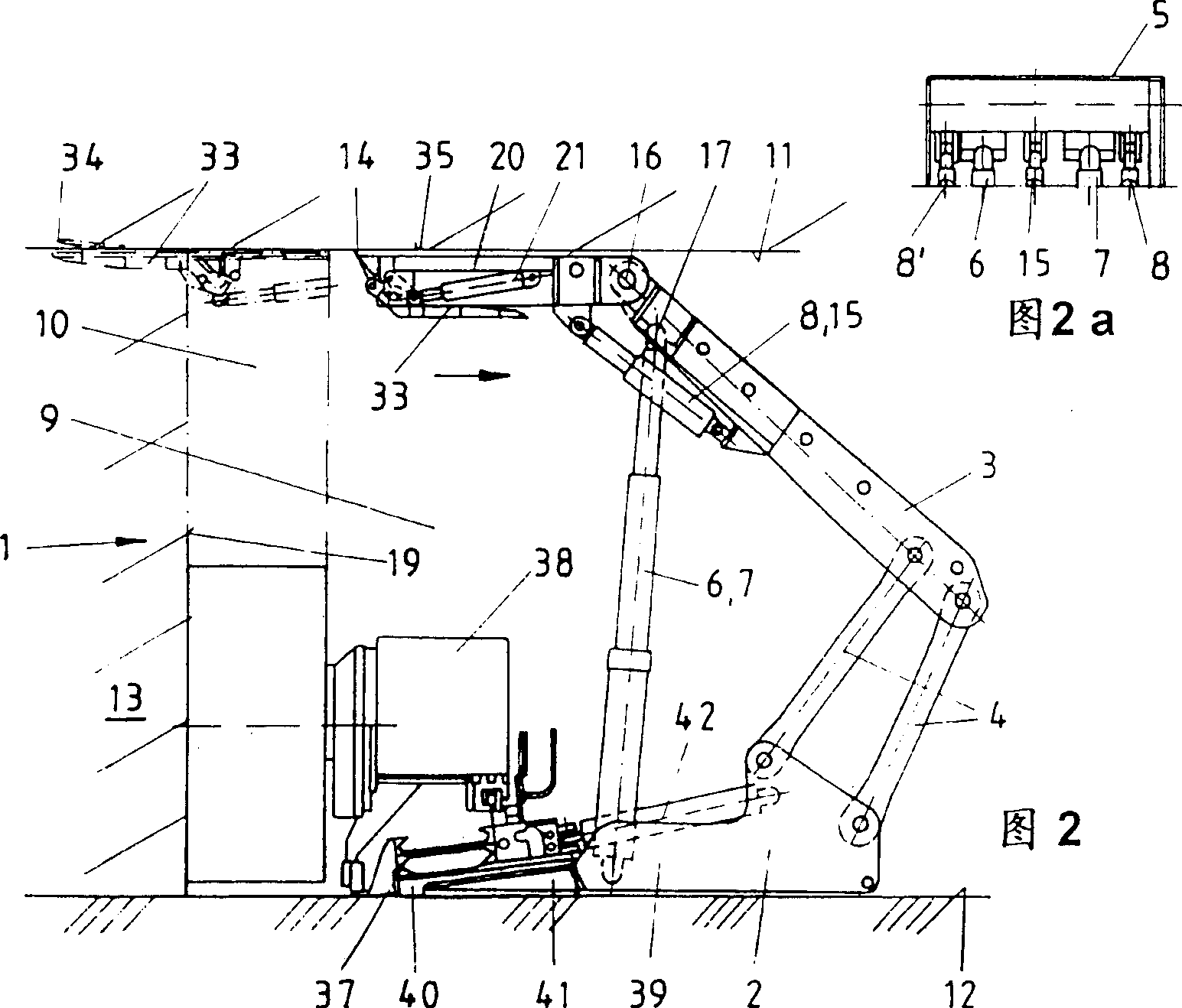

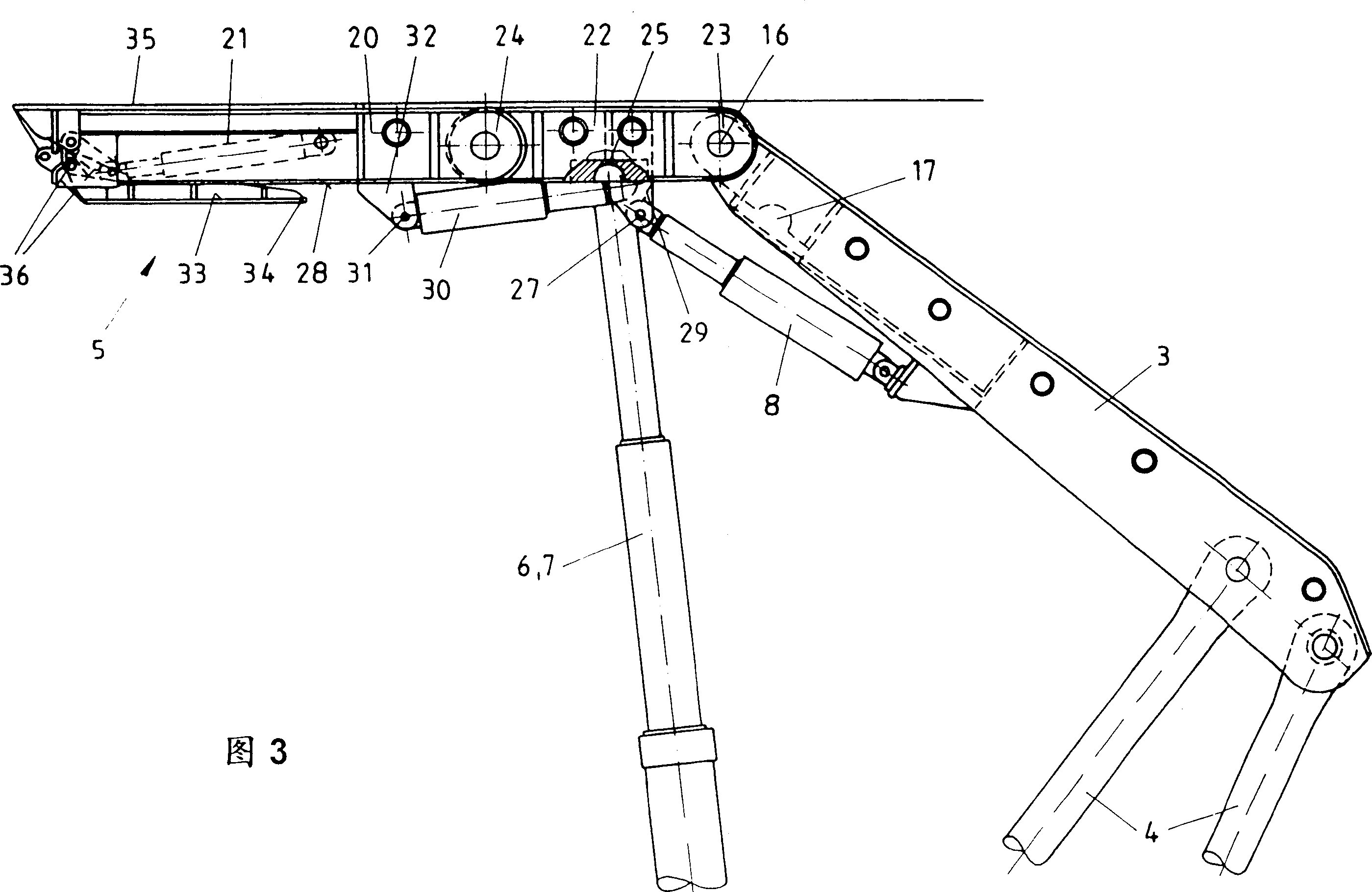

[0019] exist figure 1 A screen bracket is shown in , which is called a composite screen bracket. This shield bracket 1 is similar to the usual form, has a solid base 2, a shield beam 3 hingedly connected to the base 2 by a four-bar linkage mechanism 4 and a top beam 5, which passes through hydraulic columns 6, 7 between the top plate 11 and the bottom plate 12 Tighten, the hydraulic column 6,7 is then supported on the support base 2. FIG. 2 a shows the situation of two hydraulic columns 6 , 7 .

[0020] The special structure of the cover support 1 enables the opening space 9 in the direction of the coal wall 10 to be maintained, and the cover beam 3 ensures that the cover support stops the falling gravel under the action of the limit jack 8 .

[0021] The coal seam 13 depicted here is at least partially mined by a shearer 38 at which time the coal is then removed by a longwall face conveyor 37 .

[0022] despite figure 1The shield 1 shown is referred to as a conventional s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com