Oil gas pipeline leak intelligent on line monitoring method based on distribution type optical fibre sensor

A distributed optical fiber and sensor technology, used in optical instrument testing, machine/structural component testing, instruments, etc., can solve problems such as long time, low positioning accuracy, and unpredictable leakage hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles of the present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments completed by the inventor according to the technical solution, and the present invention is not limited to these embodiments.

[0026] The intelligent online monitoring method for oil and gas pipeline leakage based on distributed optical fiber sensors of the present invention comprises the following steps:

[0027] 1) Lay one or several optical cables in parallel with the oil and gas pipeline near the oil and gas pipeline, and use the optical fiber as a sensor to monitor the oil and gas pipeline in real time;

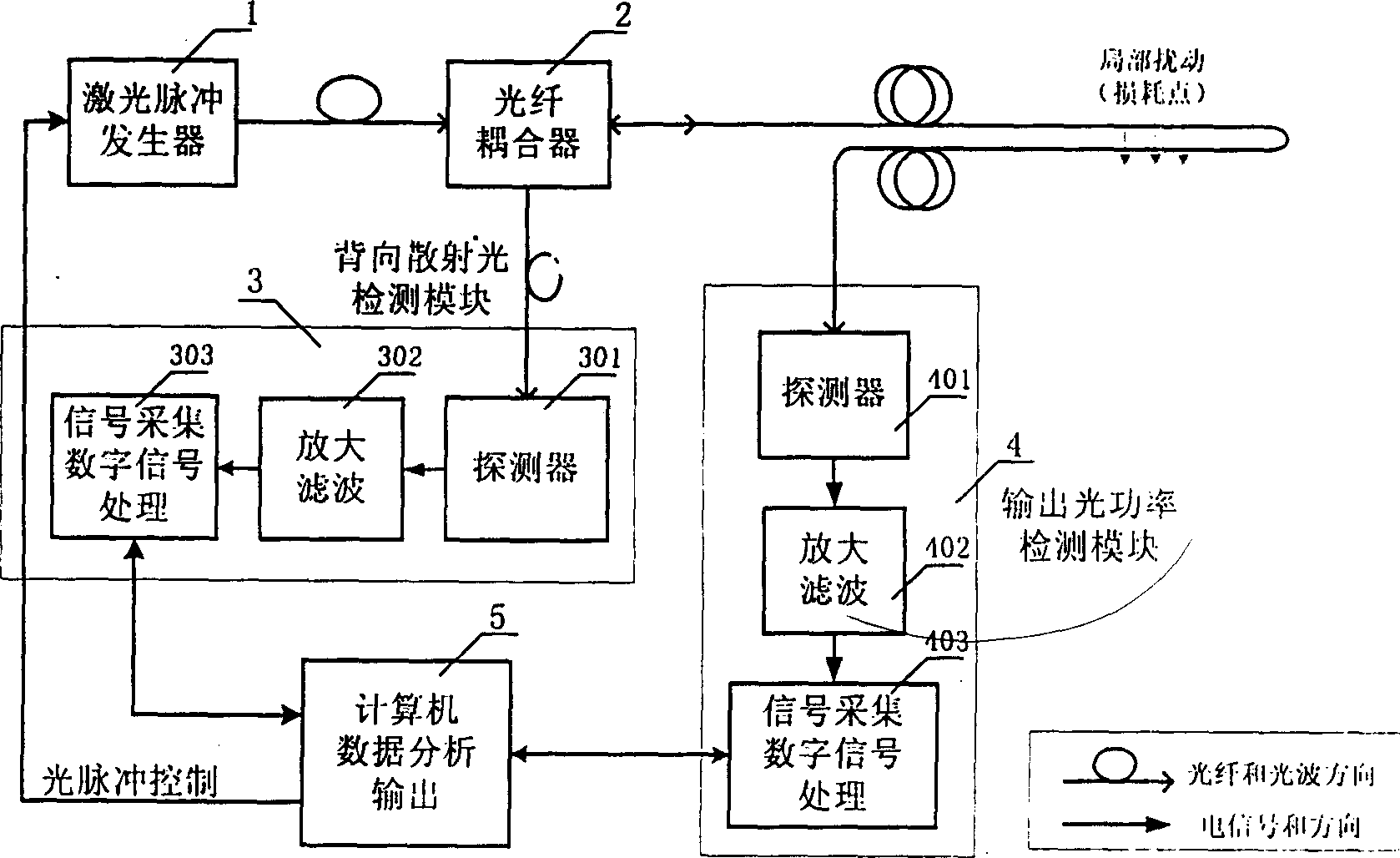

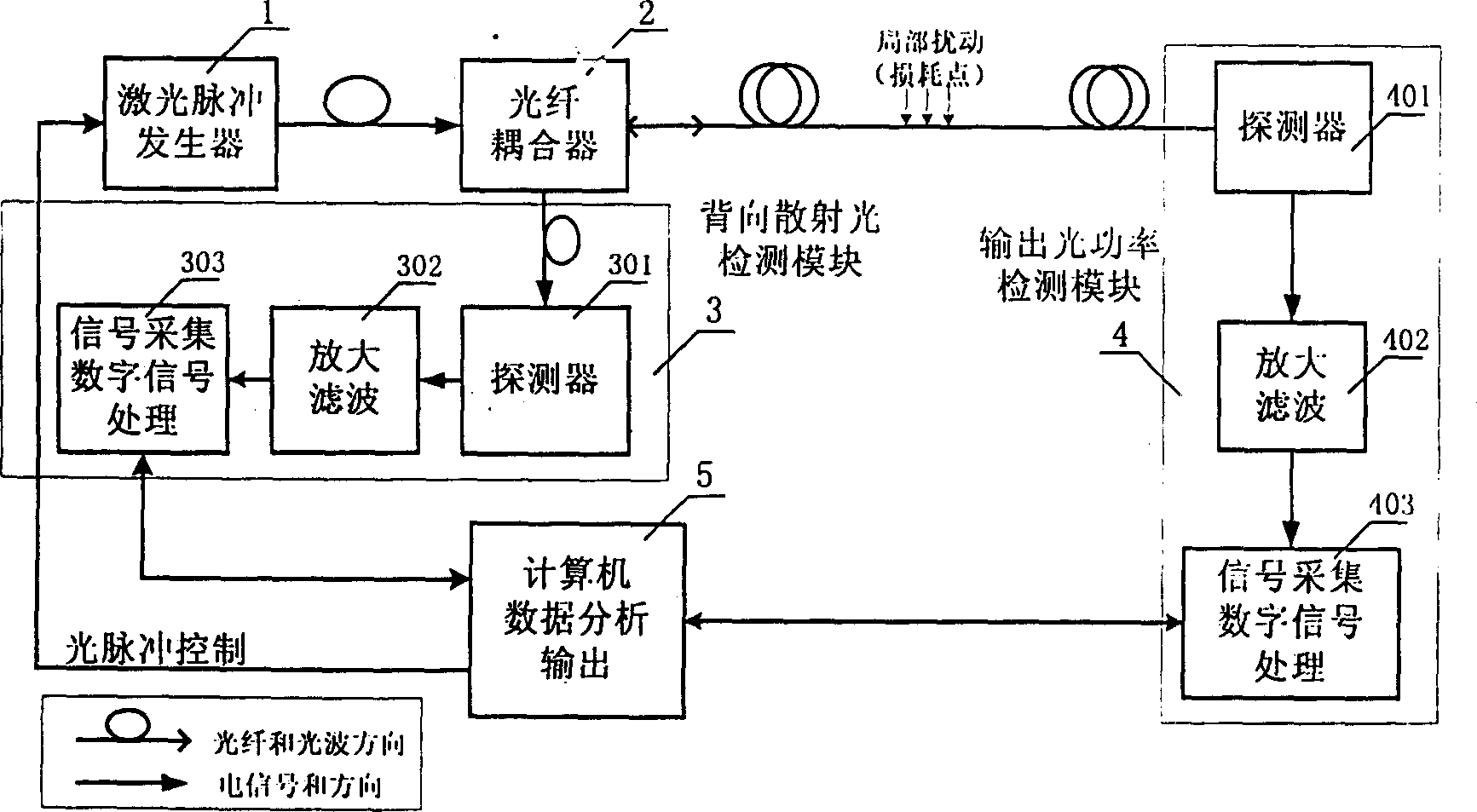

[0028] 2) At both ends of the optical fiber, that is, the input end and the output end of the oil and gas pipeline, a backscattered light detection module 3 and an optical fiber output optical power detection module 4 are arranged;

[0029] At one end of the optical fiber, that is, the input end of the optical pulse, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com