Ceramic envelope device, lamp with such device

A technology of ceramic shells and components, used in discharge lamps, electrical components, gas discharge lamps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

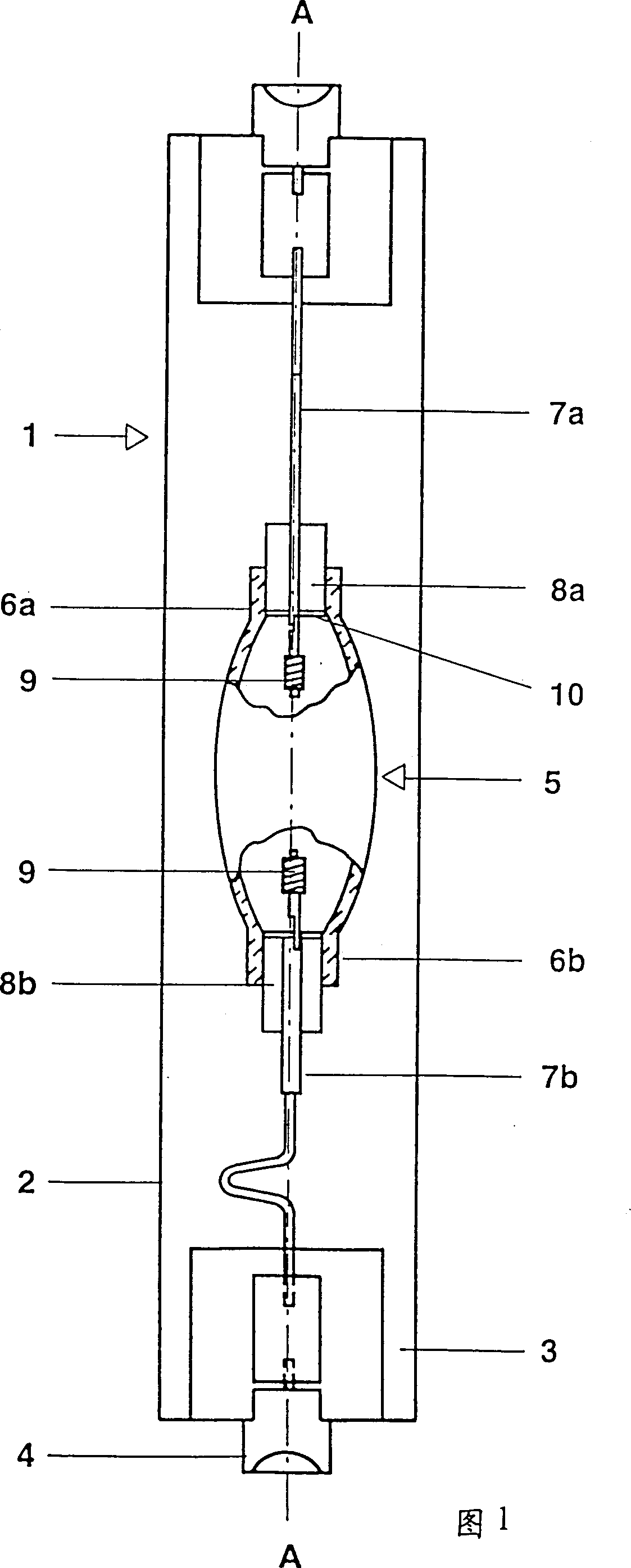

[0094] To illustrate, first refer to FIG. 1, which shows a highly schematic view of a metal halide discharge lamp 1 with a rated power of 150W. This lamp has a substantially cylindrical shell 2 made of quartz glass, which is compressed and sealed at its end 3, and has a base 4. The ceramic shell assembly 5 functions as a discharge vessel or arc tube, and it is enclosed in the shell 2. The ceramic shell assembly 5 is made of alumina, which determines the central longitudinal axis A and has two ends. For example, it is made into a cylindrical tube (not shown) or it protrudes outward at the center as shown in the figure. It forms cylindrical ends 6a and 6b at both ends. The two current through wires 7a, 7b are matched with ceramic (cermet) end plugs 8a, 8b, and the end plugs 8a, 8b are located at the ends 6a and 6b.

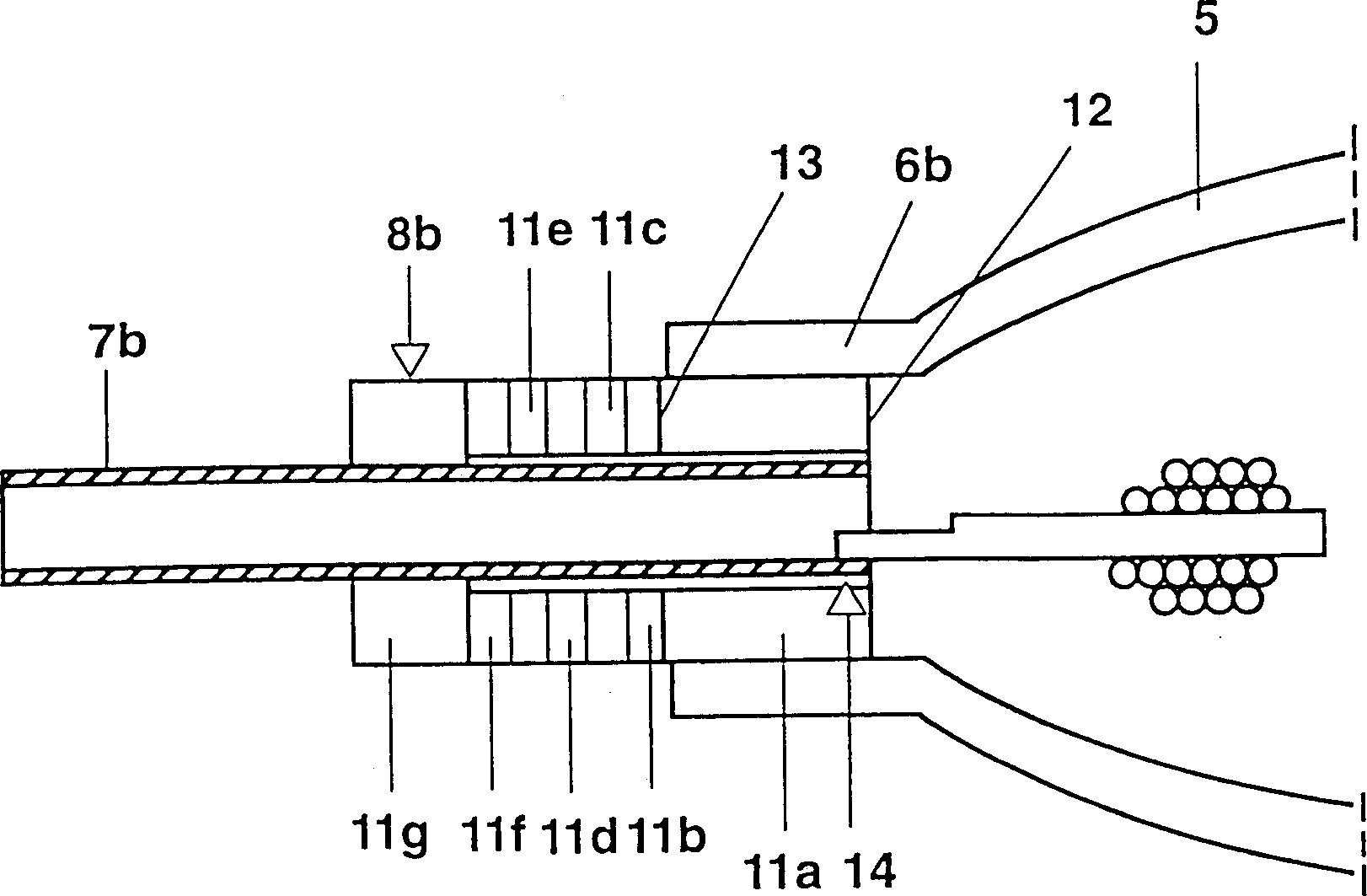

[0095] The first current through wire 7a is a molybdenum rod, which is sintered directly into the first end plug 8a at the first end 6a. The end plug is a single-piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com