Serial multi-stage process and its compact equipment for fast gas-solid separation and settling

A gas-solid rapid separation and settling device technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as easy coking, large oil and gas retention space, etc., to eliminate oil and gas retention space and product distribution Improve and avoid the effect of coking

Inactive Publication Date: 2004-11-17

CHINA UNIV OF PETROLEUM (BEIJING) +1

View PDF13 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In U.S. Patent No. 5,314,611 (1994), there is also a cyclone arm type gas-solid rapid separation with a closed cover, which can realize efficient and rapid separation of catalysts and rapid extraction of oil and gas, but this patent does not specify the cyclone. The specific structure of the flow arm type gas-solid rapid separation device, and the oil and gas stagnation space outside the closed cover is too large, which is still easy to cause coking

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

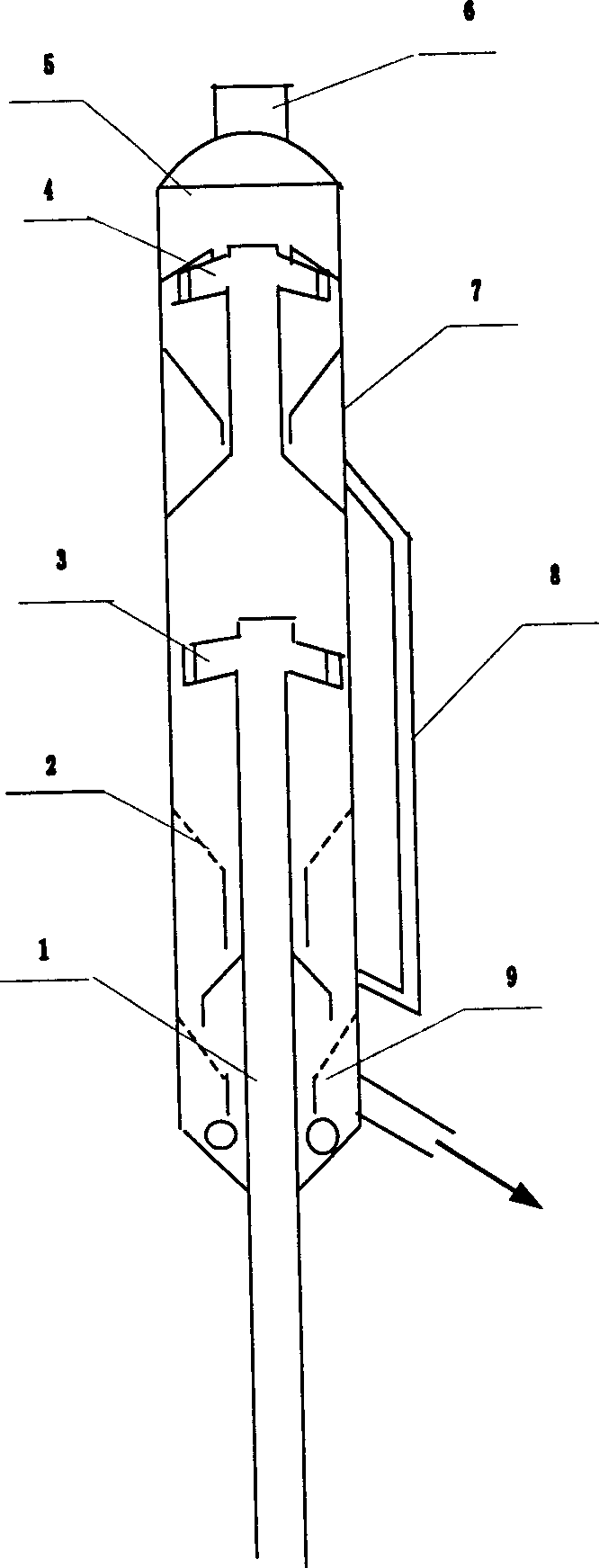

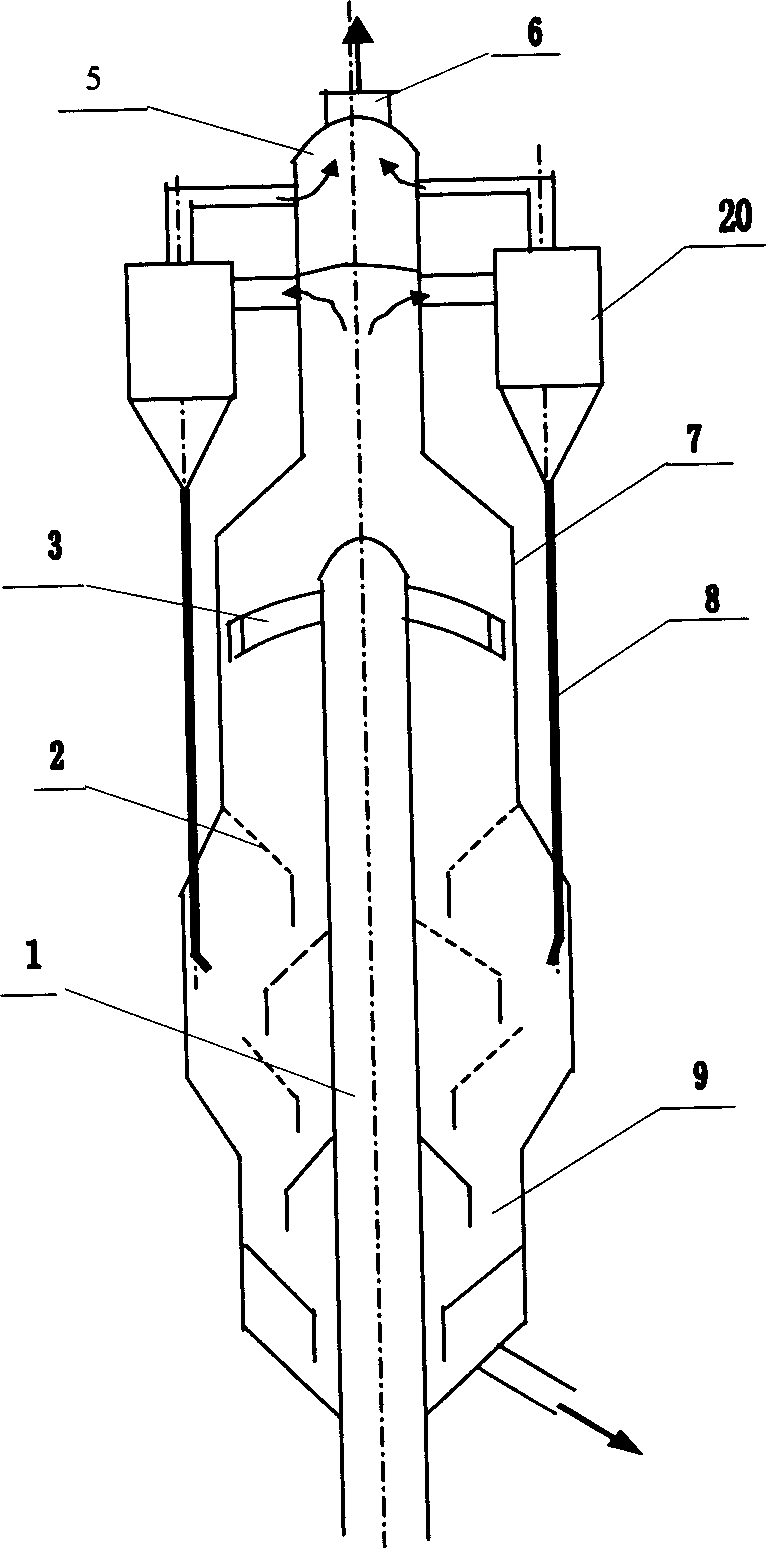

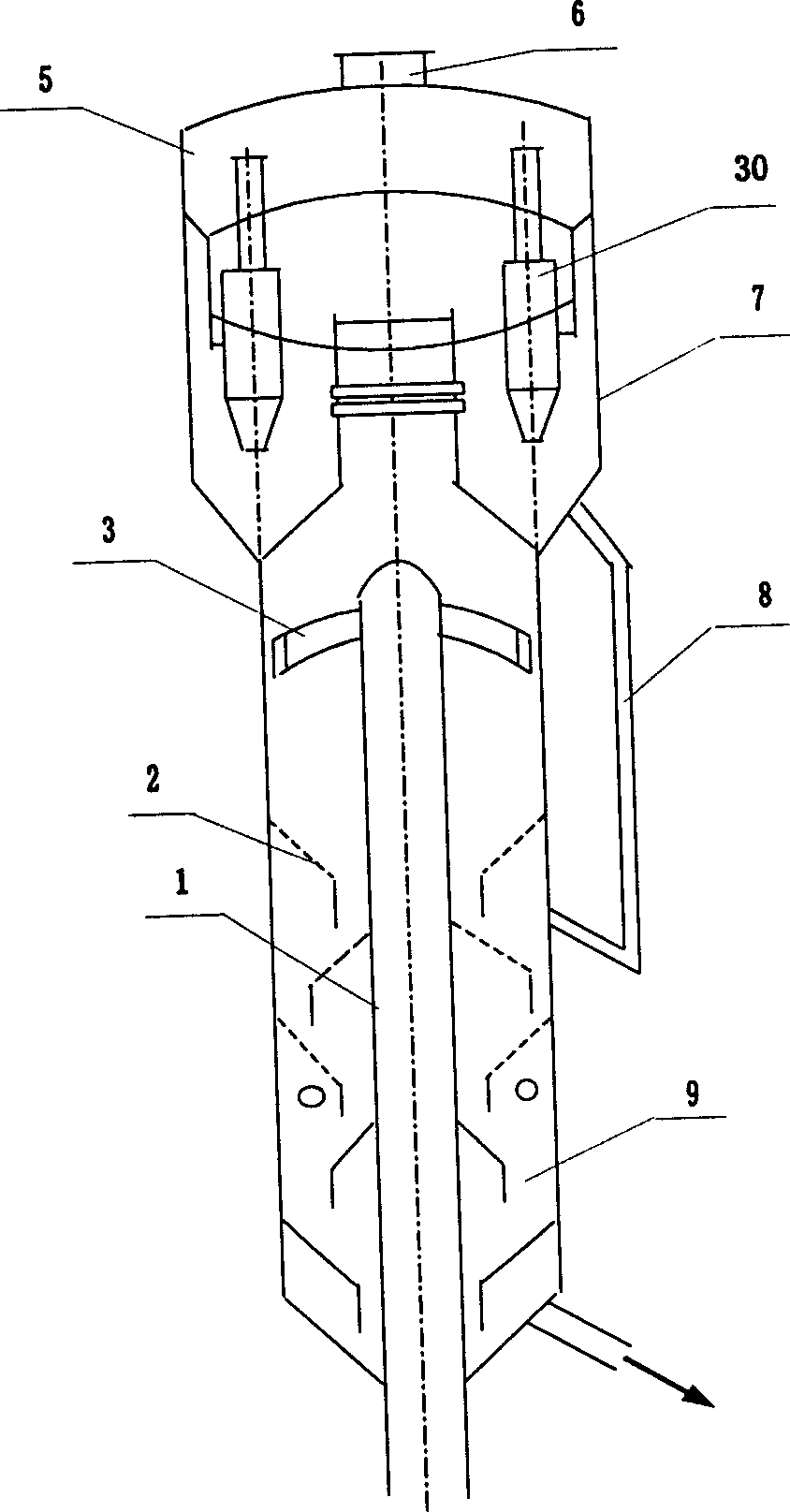

[0042] The main difference between Embodiment 3, Embodiment 2 and Embodiment 1 is: Embodiment 2 uses multiple parallel cyclone separators 20 to replace the secondary cyclone type quick separation 4 of Embodiment 1, and uses cyclone separator material leg 81 to replace the lower Material pipe 8; embodiment 3 adopts multi-tubular cyclone separator 30 to replace the secondary cyclone type quick separation 4 of embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A fast gas-solid separating and depositing process and apparatus used for outlet of lift pipe in fluidized catalytic cracking technology is disclosed. Its apparatus is composed of fast cyclone separator, feeding pipe, the combination of cyclone separator and cyclone pipe, and settling equipment. Its stage-1 fast cyclone separator, stage-1 stripping segment, stage-2 stripping segment, stage-2 fast cyclone separator, gas collecting chamber and oil-gas pipeline are serially connected. Its advantages include small size of settling equipment, short stay time of oil (gas) in settling equipment to prevent coking and improve distribution of products.

Description

[0001] Involved areas [0002] The invention belongs to the field of petrochemical technology, and relates to an oil refining and chemical process and its equipment, in particular to a method and device for rapid separation of gas and solid at the riser outlet of the fluidized catalytic cracking process and a settler. Background technique [0003] At the outlet of the riser of the fluidized catalytic cracking reaction system in the refinery, a gas-solid rapid separation device is installed to realize the separation of catalyst and oil and gas, and terminate unnecessary excessive reaction. There are currently two types of such separation devices. The first type is inertial gas-solid rapid separation device, which relies on the gas-solid two-phase inertial difference generated when oil and gas containing a large number of catalyst particles change the flow direction sharply to achieve gas-solid separation. Typical inertial gas-solid rapid separation devices have inverted L-type,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D45/12C10G11/18C10G47/30

Inventor 卢春喜张立新魏耀东陈俊武时铭显张韩金有海南春祥赵合俊

Owner CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com