Production method of high strength mixed rare earth metal filament core-spun wire

A technology of mixing rare earths and production methods, which is applied in the field of cored wire processing, can solve the problems that cannot meet the requirements of steelmaking production, etc., and achieve the effects of eliminating the deterioration of mold flux, increasing the yield of rare earths, and reducing the oxidized inclusions of rare earths

Inactive Publication Date: 2004-12-15

武钢集团有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, it still cannot meet the requirements of steelmaking production

Method used

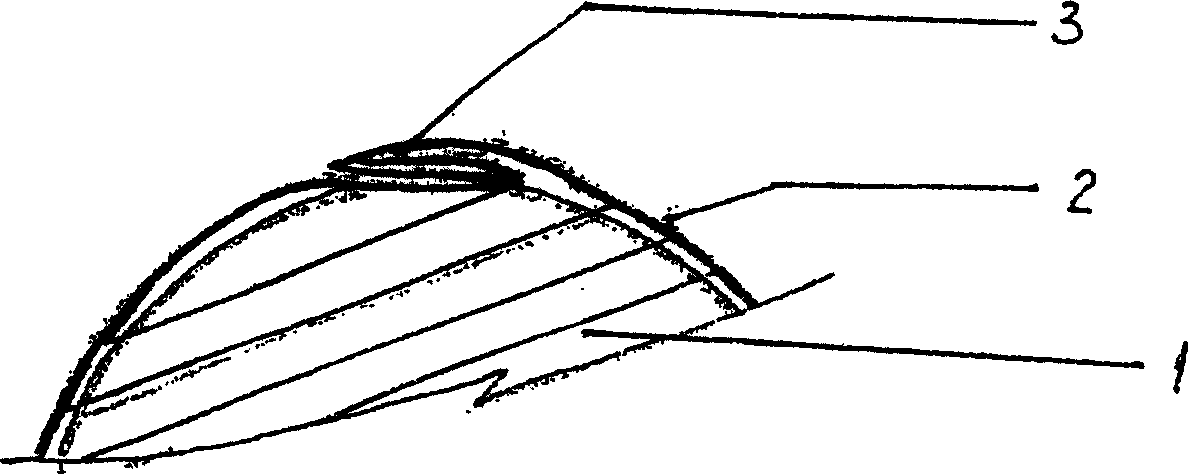

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0015] Improve the domestic GBX-5 core wrapping machine, reduce 13 sets of rolling wheels to 8 sets of rolling wheels, and change the composition to RE-Ce 45 La 32 Nd 8 The mixed rare earth metal wire with a diameter of 2.5mm and the nominal size: δ=0.15mm, d=16mm. The 08Al soft strip is processed into a cored wire with a diameter of 3.0±0.2mm by continuous coating with 8 sets of rolling wheels. The output speed can be adjusted arbitrarily.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

THe GBX-5 type wire covering machine made in China is modified. Thus, 13 sets of rolling wheels are reduced to 8 sets of rolling wheels. The wire of mixed rare earth RE-Ce45La32Nd8 is as the law material, and 08AI flexible strip steel as the covering material. The repeated sewing mode with two sides and two layers is adopted. Continuous processing through 8 sets of rolling wheels groups obtains the covered wire with diameter 2.5-5.5 mm. The speed of manufacturing wire can be adjusted at will. The invented method provides the features of reducing the encrusting matter of oxide in the steel, increasing recovery factor of rare earth and eliminating the deterioration of the covering layer caused by the oxide of the rare earth.

Description

Technical field: [0001] The invention relates to the technical field of cored wire processing, in particular to a RE-Ce 45 La 32 Nd 8 A production method of a high-strength mixed rare earth wire cored wire. Background technique: [0002] At present, the rare earth additives used in steelmaking are mostly naked cerium-rich (Ce ≥ 45%) mixed rare earth metal wires, which are continuously added to the molten steel in the mold of the continuous casting machine through special wire feeding equipment. Metamorphic inclusions, deoxidation and desulfurization to purify molten steel and microalloying, improve the physical and chemical properties of steel. However, due to the low melting point (861°C) of cerium (Ce ≥ 45%), which is the main component in the naked cerium-rich (Ce ≥ 45%) mixed rare earth metal wire, when it is added, it will melt at high temperature when it penetrates the mold slag layer, forming a large amount of Rare earth-oxygen-sulfur inclusions lead to deteriorat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22D11/08C21C7/00C22C35/00

Inventor 高平祥韩永泽柴钟山王跃华万恒瑜

Owner 武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com