Suction cleaner

A technology for vacuum cleaners and dust collection rooms, which is applied to the installation of vacuum cleaners, electrical equipment, and cleaning equipment, etc. It can solve problems such as affecting the appearance and unpleasantness of users, and achieve the effects of reducing damage to the appearance, suppressing scratches, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

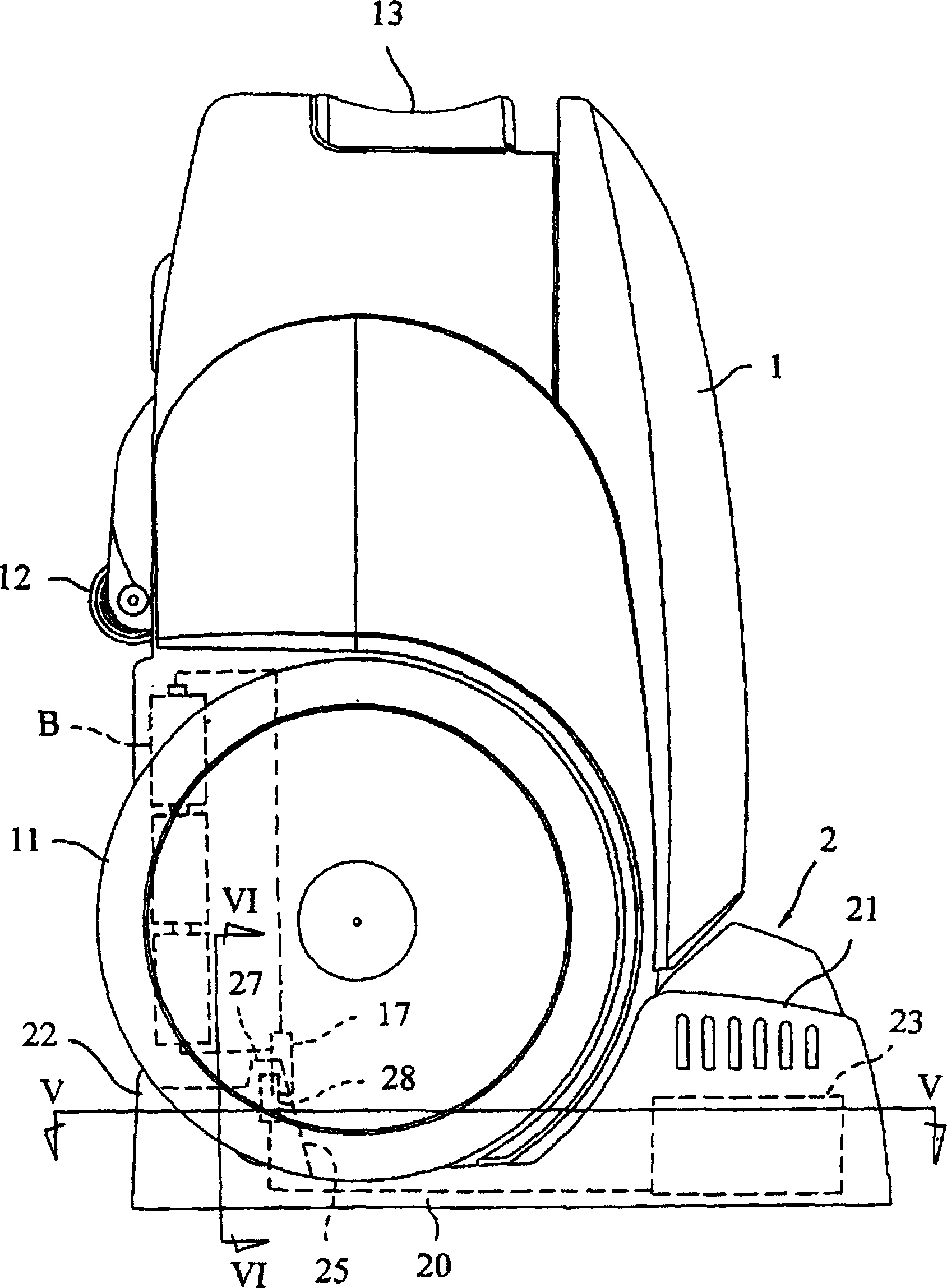

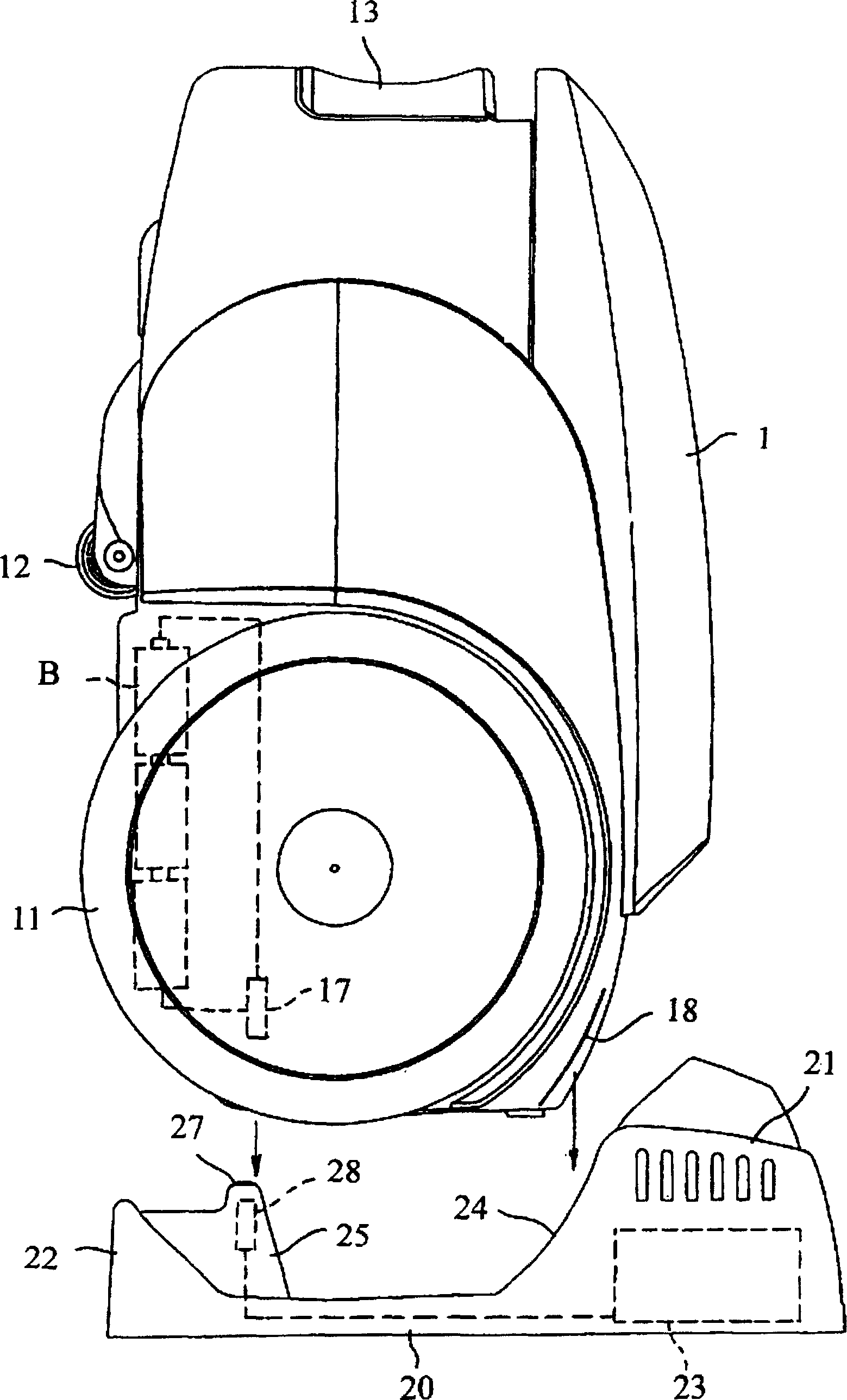

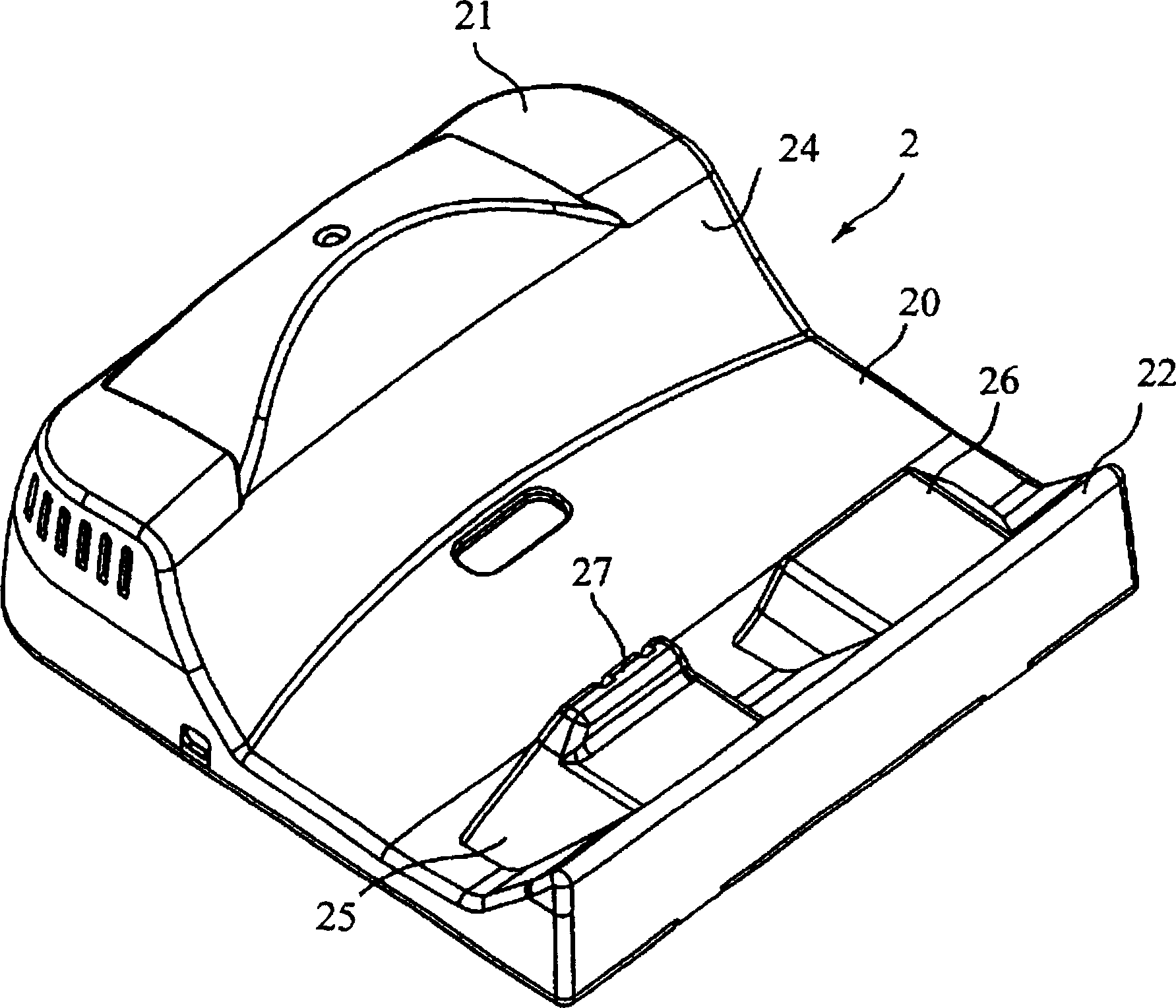

[0040] figure 1 It is a side view of the main part of the vacuum cleaner of the present invention, 1 in the figure is the main body of the vacuum cleaner, and 2 in the figure is the charging stand.

[0041] Above-mentioned vacuum cleaner main body 1 has a left and right pair of large-diameter rear wheels 11,11 (only one is shown in the figure) on its outside, and the small-diameter front wheel 12 that is made of castors, and there are electric fans and electric fans for air suction inside it. The dust collection chamber (all not showing among the figure) that catches dust usefulness, simultaneously, have suction port 13 and exhaust port 14 (referring to Figure 4 ), during use, the above-mentioned suction port 13 is connected with the suction pipe and the dust collector by a flexible suction hose.

[0042] Inside the vacuum cleaner main body 1, such as figure 1 and figure 2 As shown by the dotted line in , a battery B as a power source is housed inside, and the electric cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com