Metal corrosion-resisting testing device

A measuring device and corrosion resistance technology, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of potential difference corrosion, the inability to use numerical values to express the corrosion degree of test pieces, and low corrosion resistance , to achieve the effect of quantitative corrosion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The metal corrosion resistance measuring device of the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

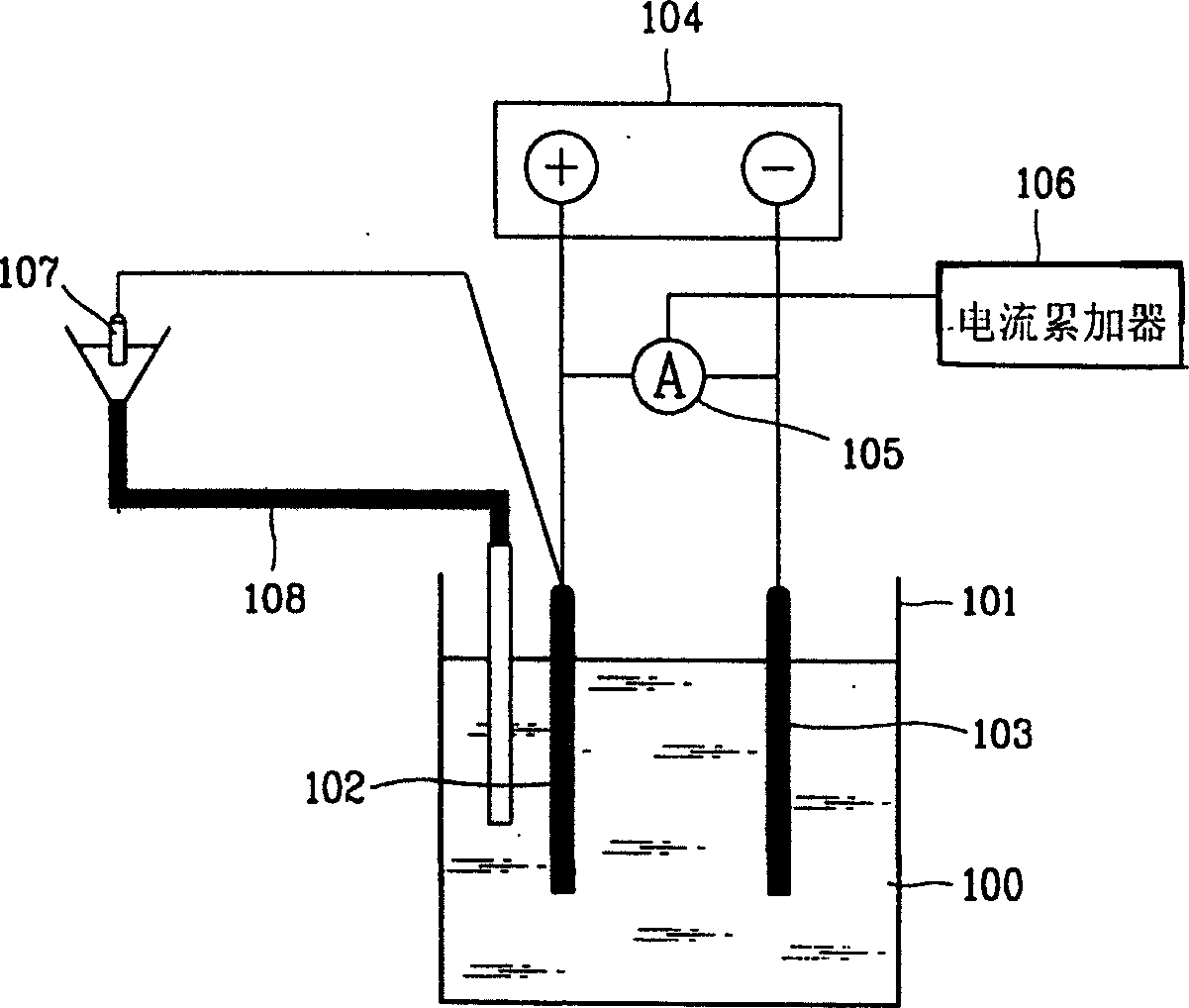

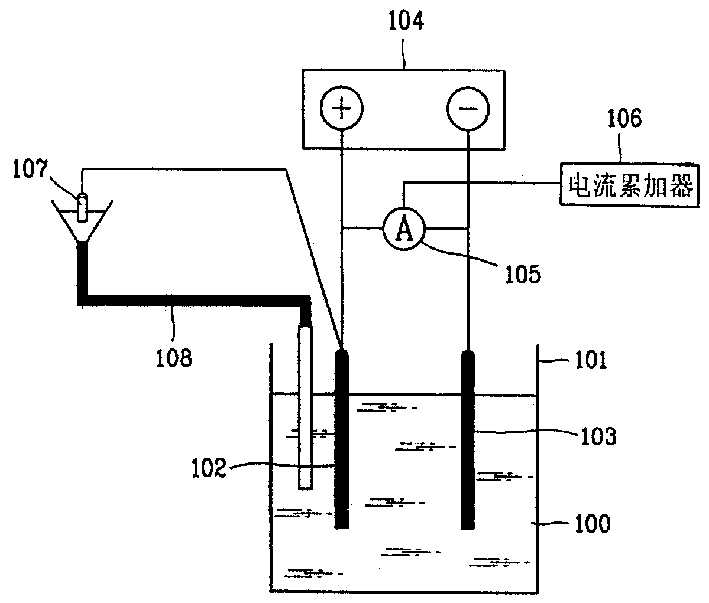

[0015] As shown in the figure, the metal corrosion resistance measuring device designed by the present invention has been immersed in the aluminum 102 of test corrosion amount and corresponding electrode copper 103 inside the container 101 that immerses 5% brine (NaCl) 100, and aluminum 102 and copper 103 The anode (+) and the cathode (-) are connected by the DC power supply 104, and there will be ion movement between the aluminum 102 and the copper 103 when the DC power supply is added, and the display anode is connected on the DC power supply 104 The ammeter 105, which changes the amount of current between the cathode, is connected to the current accumulator 106. At the same time, in order to set the reference potential, the aluminum test piece 102 is connected to the reference copper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com