Pouring-coating type coating appts. and coating method and flat member mfg. appts.

A coating device and a coating-type technology are applied in the field of sheet-like member manufacturing equipment and sheet-like member manufacturing equipment, and can solve problems such as difficulty in distinguishing coating film specifications and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

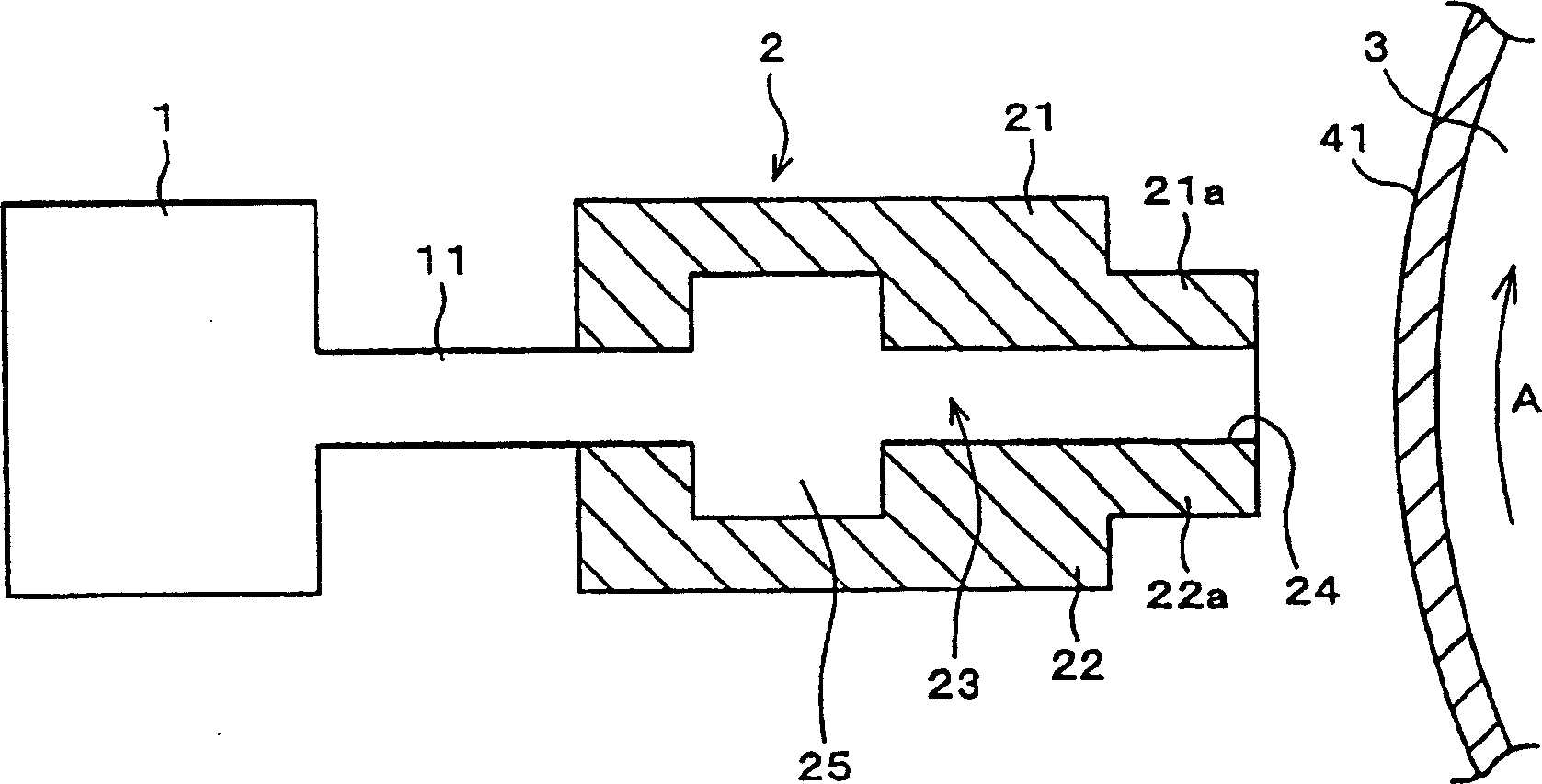

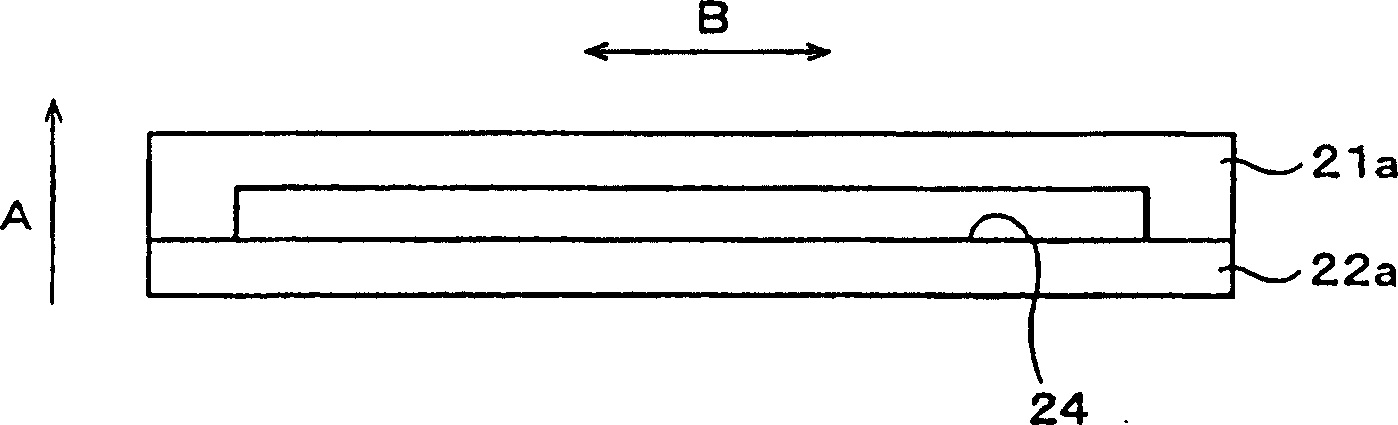

[0067] The following will refer to Figure 1 to Figure 7 Embodiments of the present invention will be discussed, but the present invention is not limited thereto.

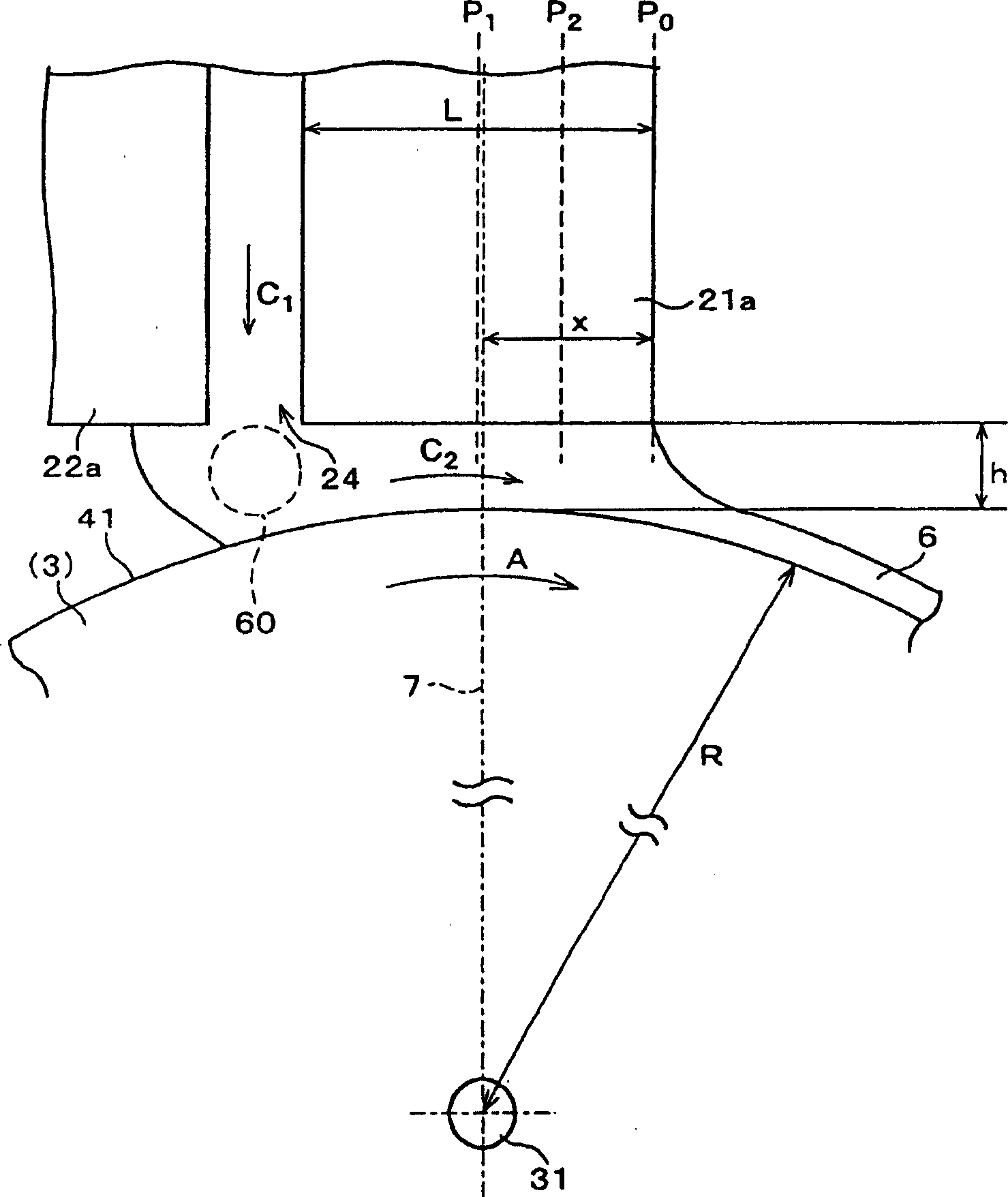

[0068] Regarding the casting coating type coating device (first casting coating type coating device) and coating method according to the present invention, when it is assumed that the reference plane includes the rotation axis of the back-up roll and is along the When the projection direction is formed, the positional relationship between the casting and the back-up roll is adjusted so that the downstream projection can be projected to some extent from the reference plane.

[0069] In the following discussion, the protruding direction of the discharge port, that is, the axial direction of the backup roll, is referred to as the "width direction", and the direction perpendicular to the width direction, that is, the direction of the coated film formed by the rotation of the backup roll The direction, as discussed bel...

no. 2 example

[0113] The following will refer to Figure 8 Let's discuss another embodiment according to the present invention. However, the present invention is not limited to the Examples. For convenience of discussion, components having functions as components used in the first embodiment are denoted by the same reference numerals, and explanations thereof are omitted.

[0114] Regarding the first cast coating type coating apparatus of the first embodiment, the coating film that has been formed on the surface of the material to be coated is continuously rotated in accordance with the rotation of the backup roll. However, the present invention is not limited thereto, and may be applied to a cast coating type coating device that does not use a coating material. The cast coating type coating apparatus which does not use a coating material is called the 2nd cast coating type coating apparatus of this invention.

[0115] As an example of the 2nd casting coating type coating device accordin...

no. 3 example

[0133] Another embodiment according to the present invention will refer to Figure 9 to discuss. The present invention is not limited to this example. To simplify the discussion, components having functions as components used in the first embodiment are denoted by the same reference numerals, and explanations thereof are omitted.

[0134] In the first or second embodiment, the coating device for forming the coating film has been discussed. However, the present invention is not limited to this type of coating device, and can be better applied to a manufacturing device of a sheet-like member (manufacturing machine of a sheet-like member), which can be used to manufacture a sheet formed of a coated film. shape components.

[0135] In particular, for example, in Figure 9 As shown in (a), there is provided a first sheet member manufacturing apparatus according to this embodiment including: the first cast coating type coating apparatus (coating apparatus) 20a discussed in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com