Carbon dioxide transcrisis refrigeration circulation rolling rotor energy recovery device

A technology of rolling rotor and carbon dioxide, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of difficult application, complex structure, expander machinery, etc., and achieve the advantages of safe operation, overcoming the starting dead point, and reducing noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The arrangement of the present invention in the system is as attached Figure 5 The dashed box part in.

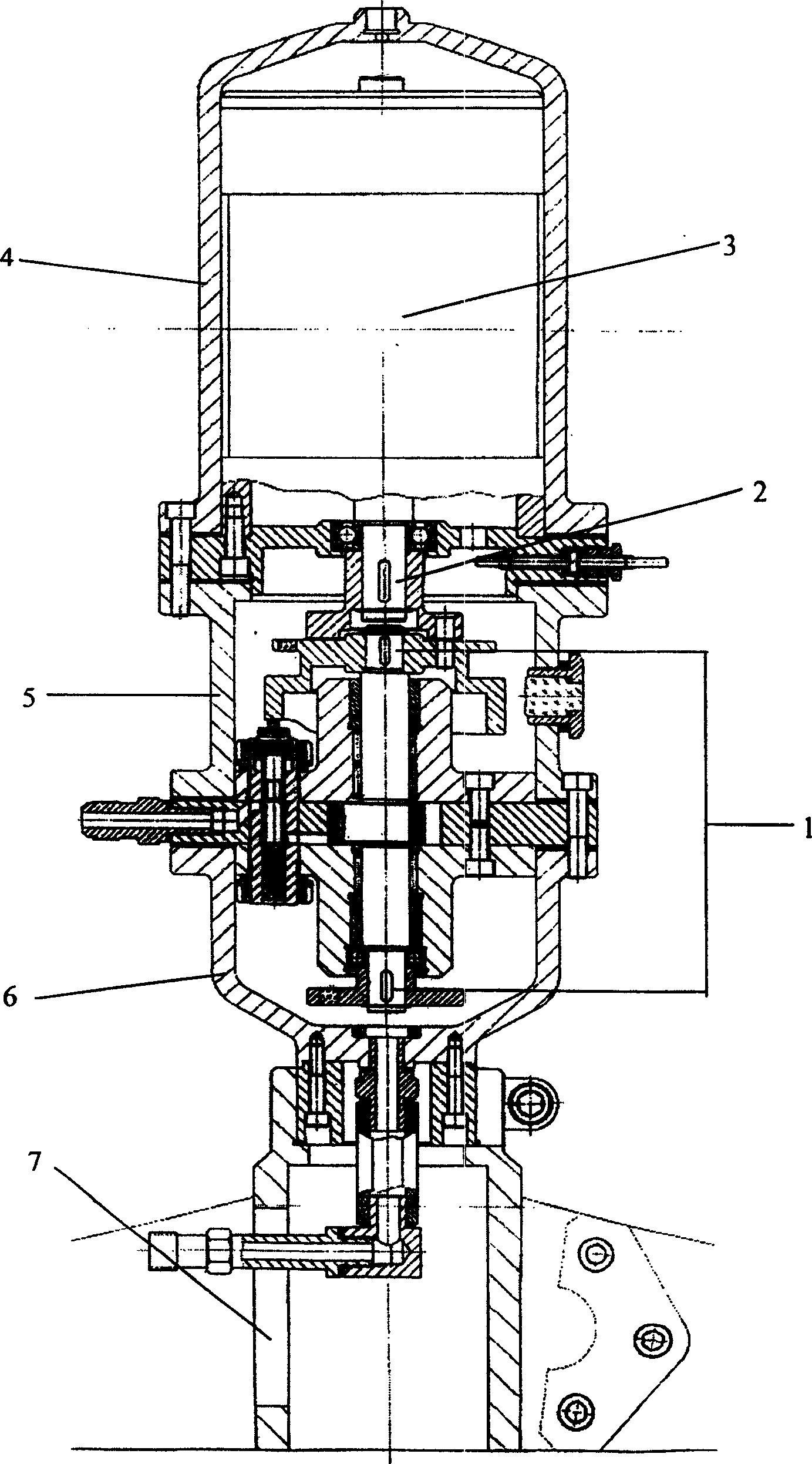

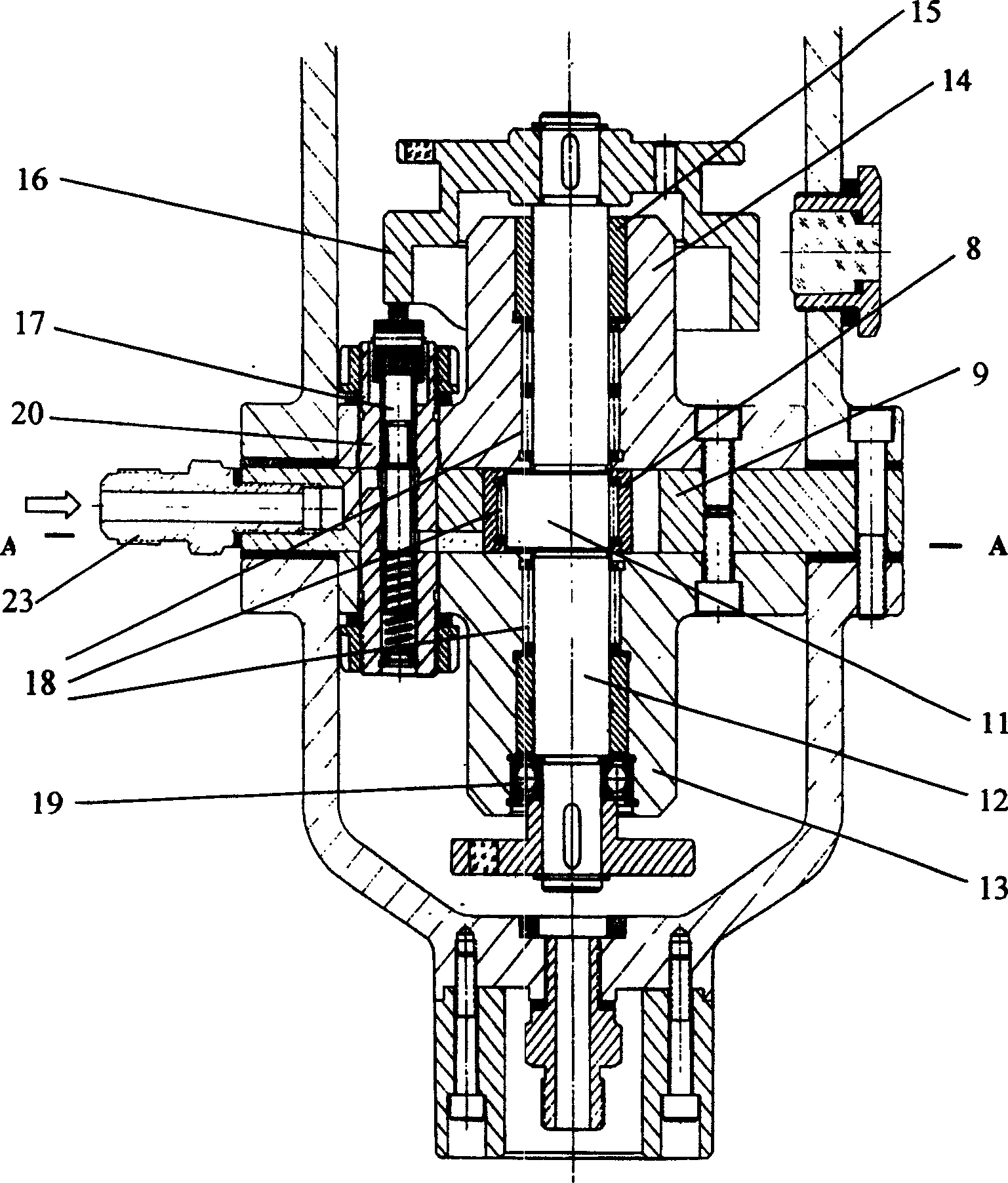

[0010] During installation, the inlet pipe 23 of the carbon dioxide transcritical refrigeration cycle rolling rotor energy recovery device (the present invention) is connected to the outlet of the gas cooler 30, and the outlet 24 is connected to the inlet of the evaporator 31. The main shaft 12 of the rolling rotor expander 1 is coaxially and vertically installed with the main shaft of the generator-motor 3 through a coupling 2. The electric energy output by the generator-motor 3 is used for the operation of the load, and the load can be a small electric device such as a water pump and a fan of the system.

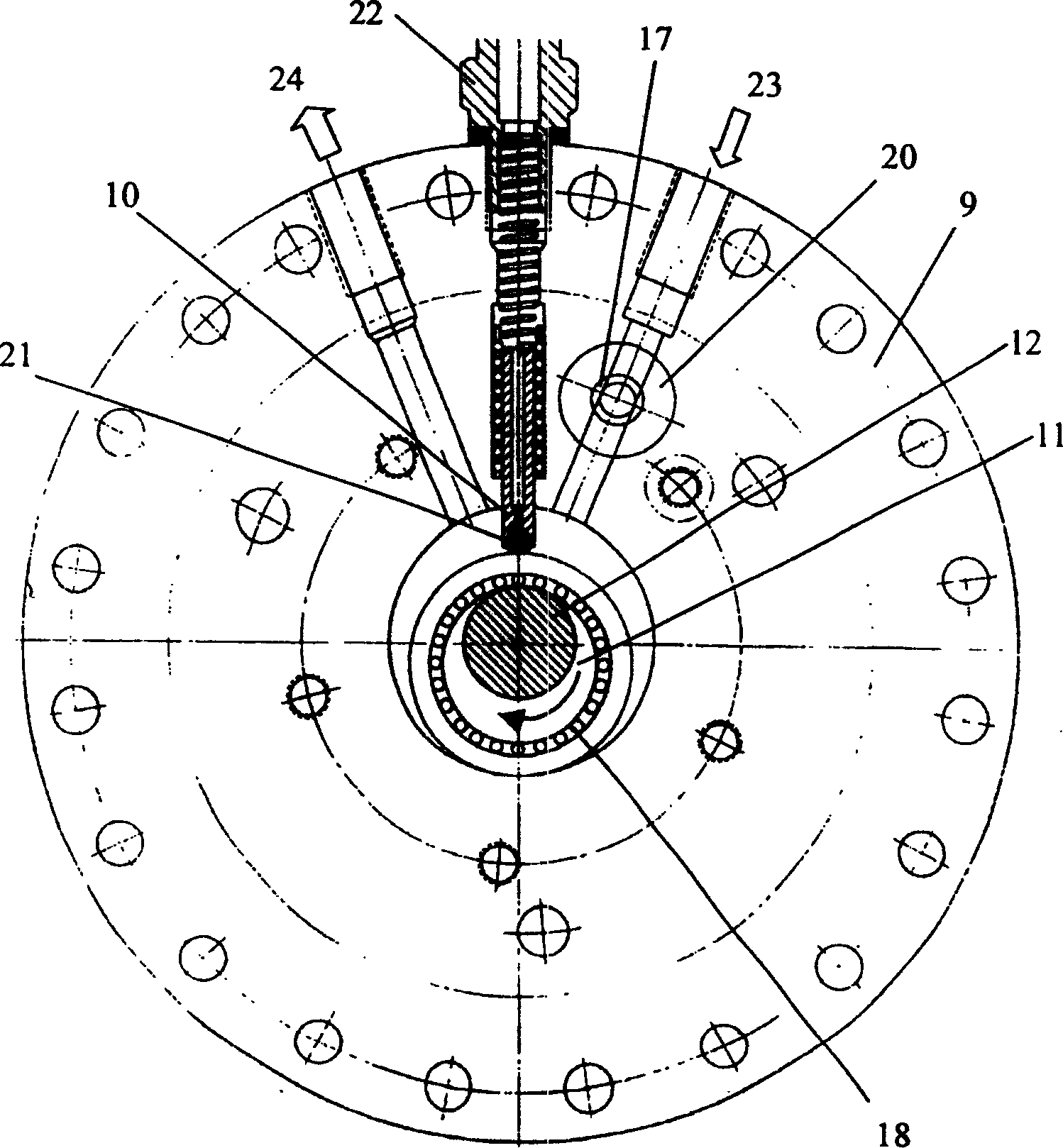

[0011] When working, press the normally open contact switch 27, the electric motor 26 of the generator-motor 3 starts, and drives the rolling rotor expander 1 to rotate in the direction shown in FIG. 3, which overcomes the starting dead point of the rolling rotor exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com