Magnetic attracted plane reflective mirror optical valves

A flat mirror and magnetic adsorption technology, applied in the coupling of optical waveguides, can solve problems such as difficult assembly, high insertion loss, and increased difficulty in installation and manufacturing, and achieve the effects of not easy to wear, high repeatability, and avoiding position changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

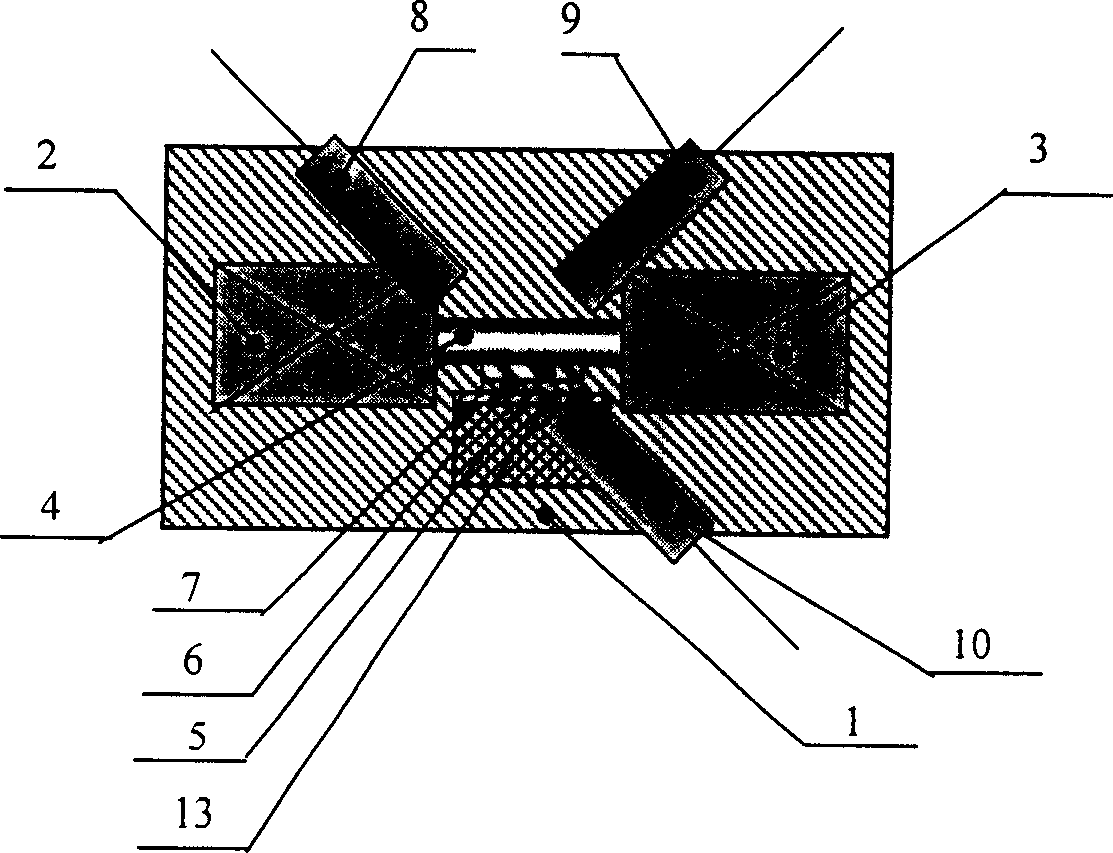

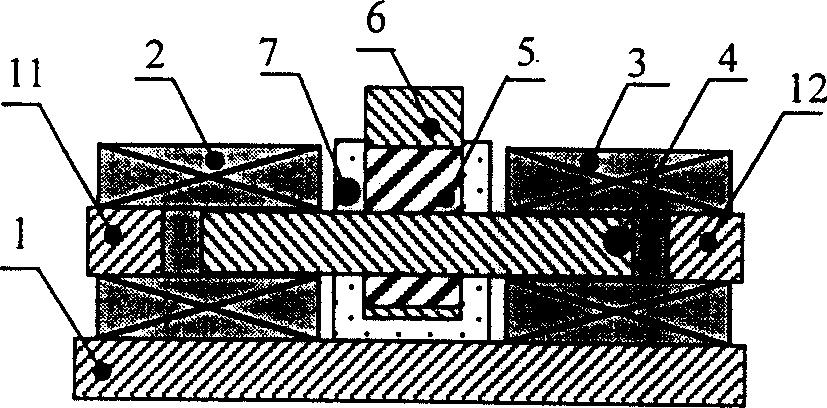

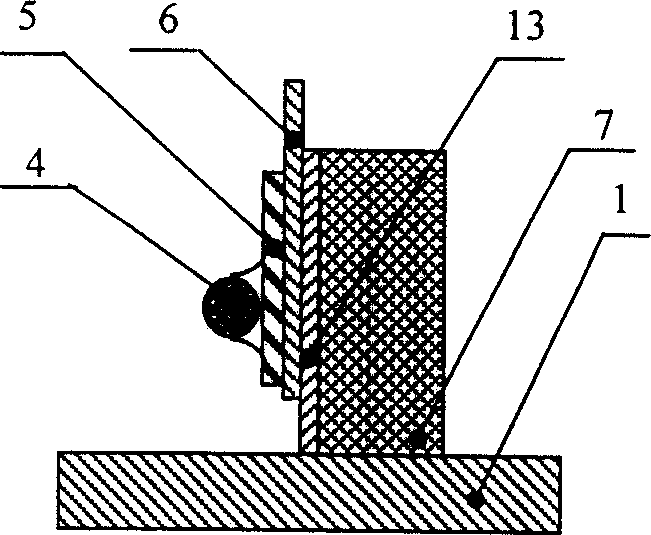

[0020] see first figure 1 and figure 2 , The optical switch of the magnetic adsorption planar mirror of the present invention includes four parts: a substrate, an optical path coupling, a magnetic adsorption holding and an electromagnetic drive. The optical path coupling part is made up of the first fiber collimator 8, the second fiber collimator 9, the third fiber collimator 10 and the plane mirror 6; the magnetic adsorption holding part includes a fixed soft magnet 7, quartz glass 13 and The movable permanent magnet 5 ; the electromagnetic drive part includes a first electromagnetic coil 2 , a second electromagnetic coil 3 , a moving shaft 4 , a first limiting block 11 and a second limiting block 12 . The latter three parts are all fixed on the base plate 1, and the base plate 1 is made of super duralumin material.

[0021] Such as figure 2 As shown, the first electromagnetic coil 2 and the second electromagnetic coil 3 of the electromagnetic drive part are symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com