Dielectric barrier discharge lamp

A dielectric barrier, discharge lamp technology, applied in the manufacture of discharge lamps, gas discharge lamps, discharge tubes/lamps, etc., to achieve the effect of cheap glass fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

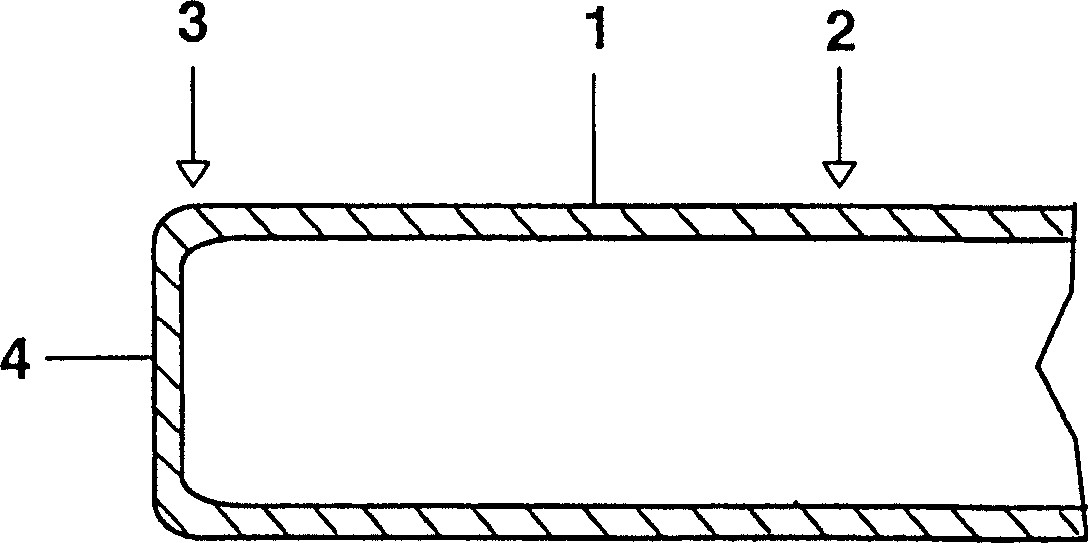

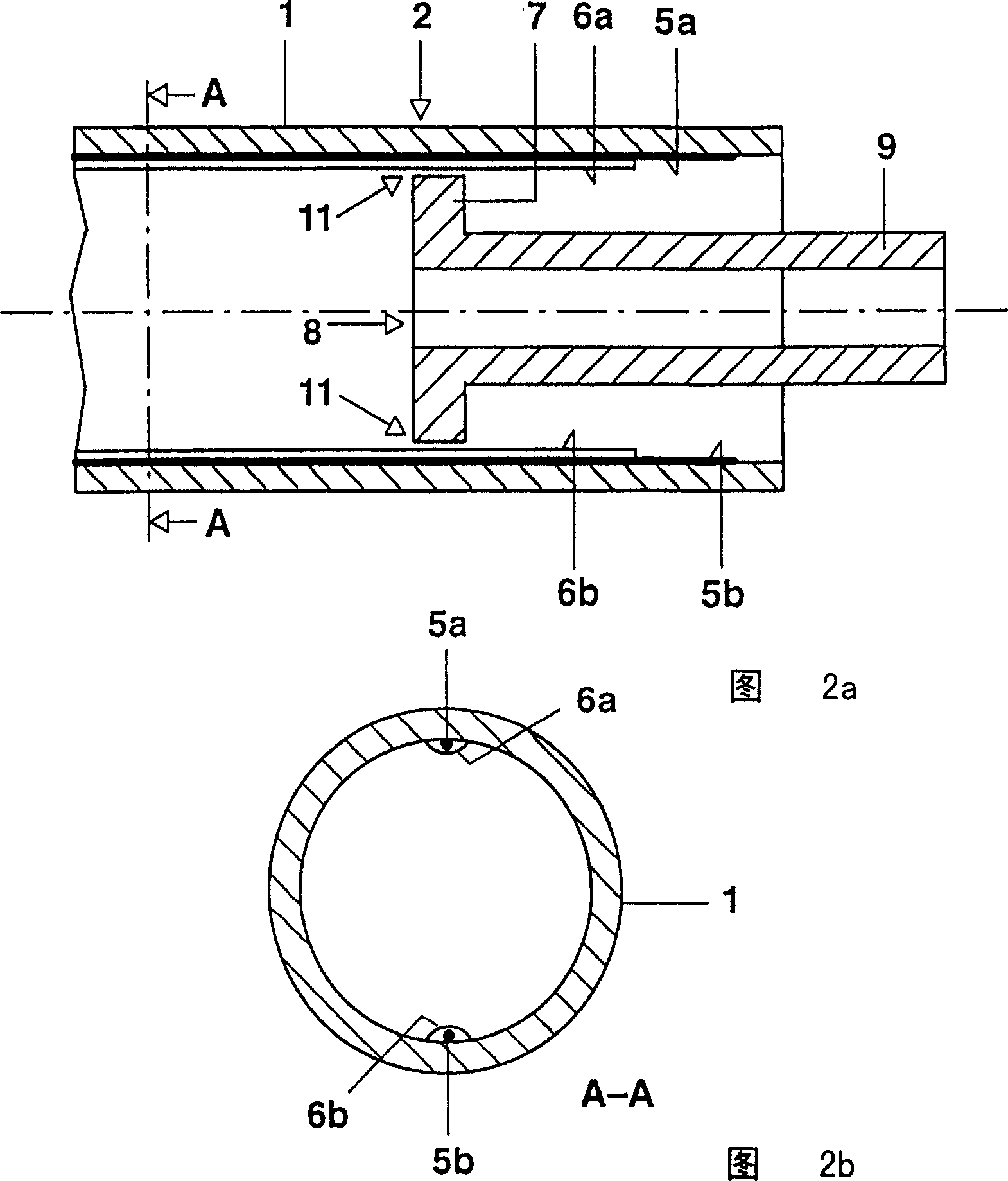

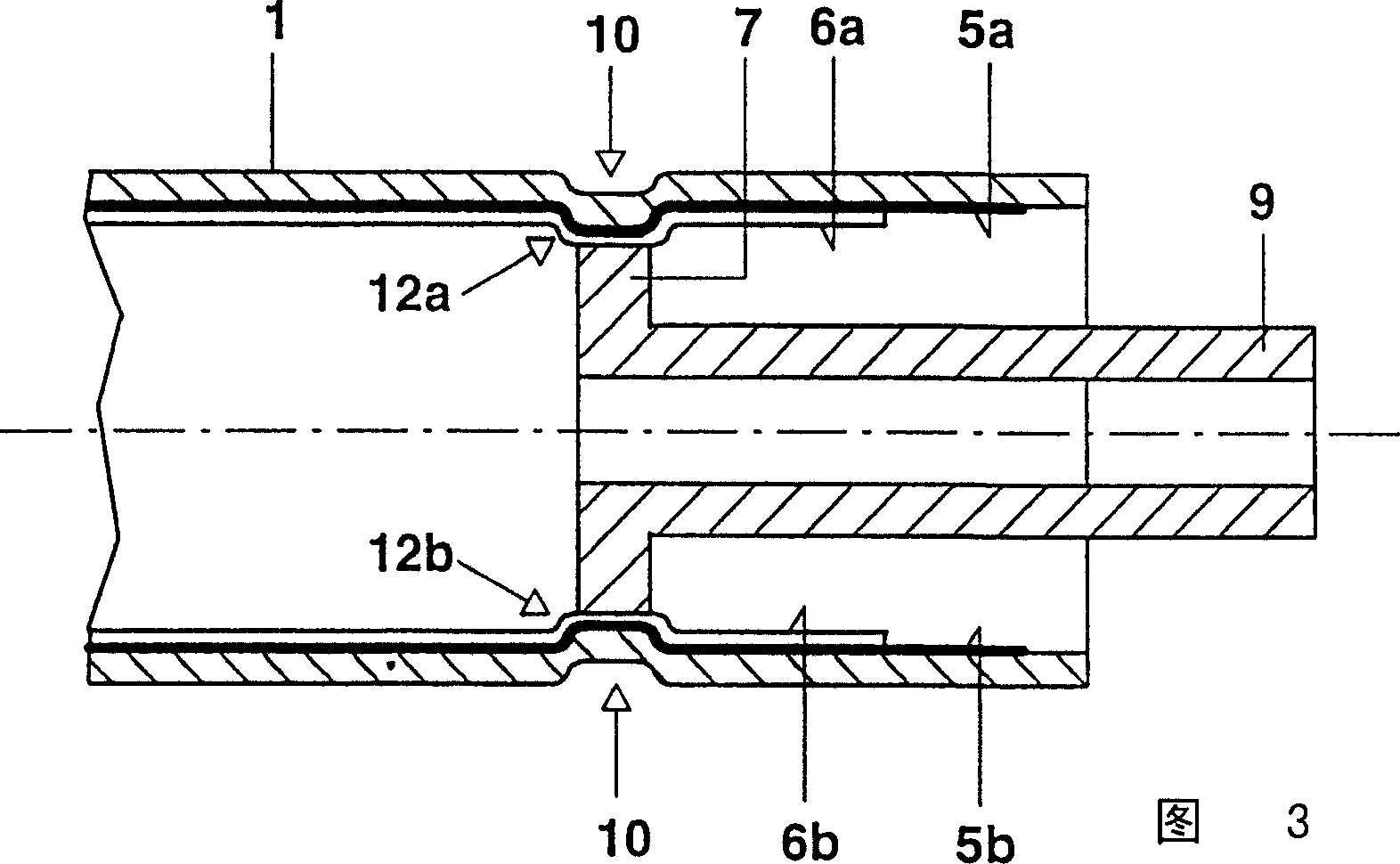

[0030] figure 1 to 3 are used to illustrate the dielectric barrier layer-discharge lamp manufacturing method of the present invention.

[0031] figure 1 A discharge vessel 1 made of soda-lime glass is shown, which is temporarily still open at a first end 2, but whose second end 3 has been sealed with a flat frit 4.

[0032] 2a, 2b respectively show a schematic longitudinal section of the open end 2 of the discharge vessel 1 and a schematic cross section along the section line A-A. The inner wall of the discharge vessel 1 has been provided with two radially arranged linear silver inner electrodes 5a, 5b which are each covered with a dielectric glass barrier layer 6a, 6b. Furthermore, a disc-shaped sealing element 7 has been arranged concentrically in the open end 2 of the discharge vessel 1 . The outer diameter of the disk-shaped sealing element 7 is slightly smaller than the inner diameter of the discharge vessel minus the thickness of the two inner electrodes 5a, 5b includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com