Plug-in device for sandwishing material between layers

A technology for inserting devices and sheet layers, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and installation of optical fibers/cables, etc. It can solve the problems of cost increase, occlusion, and efficiency reduction, and achieve the effect of reducing costs and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

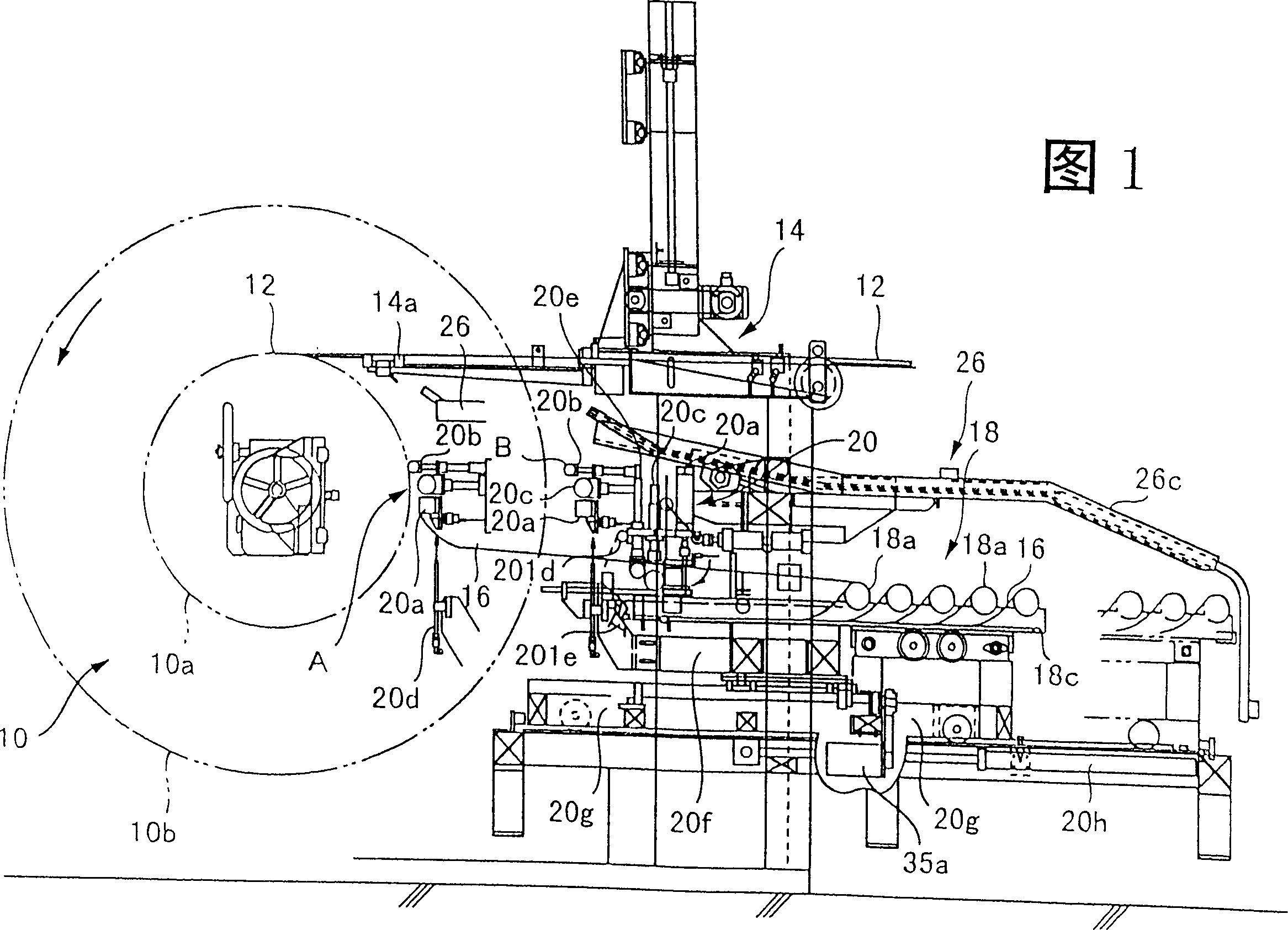

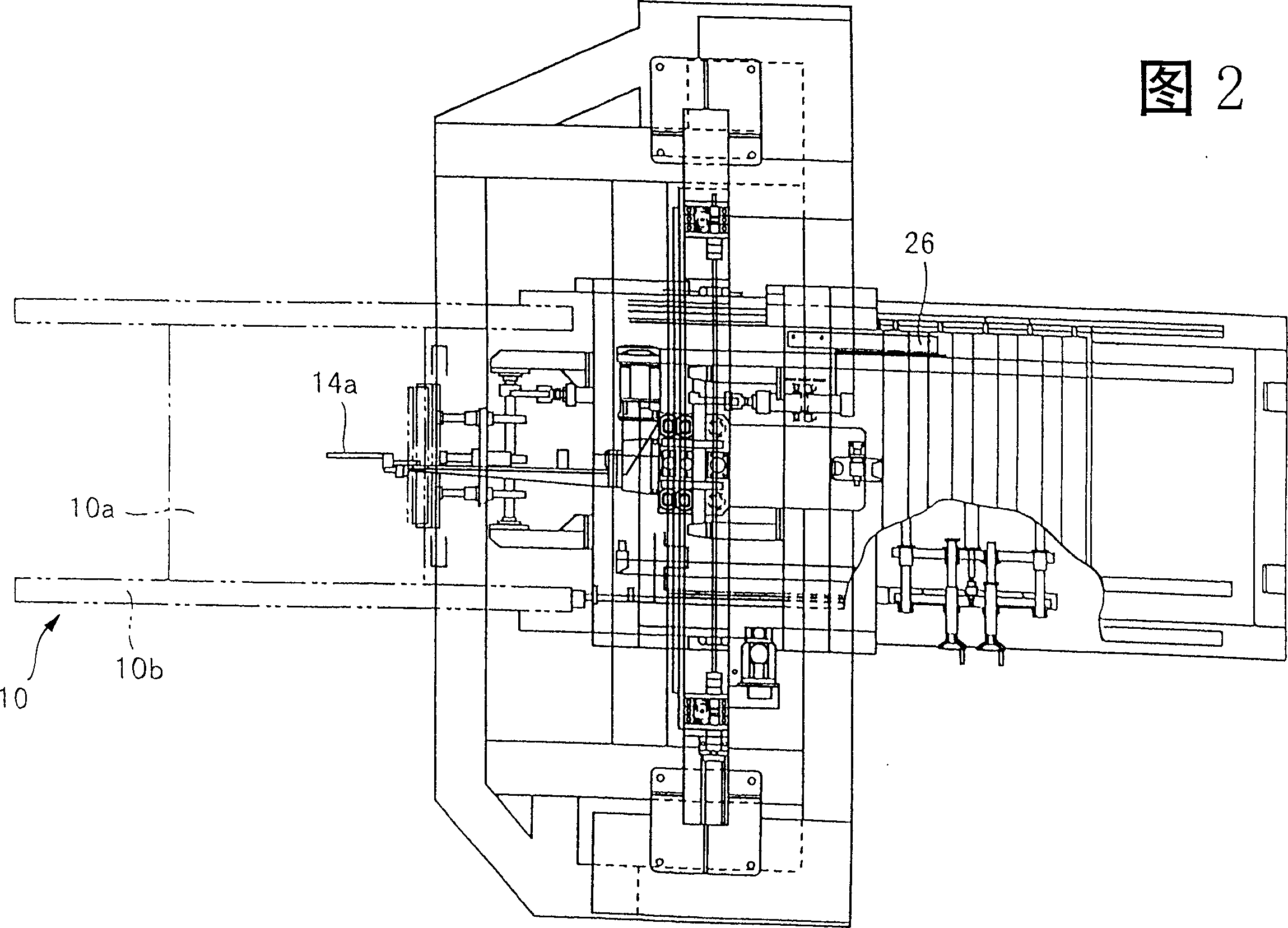

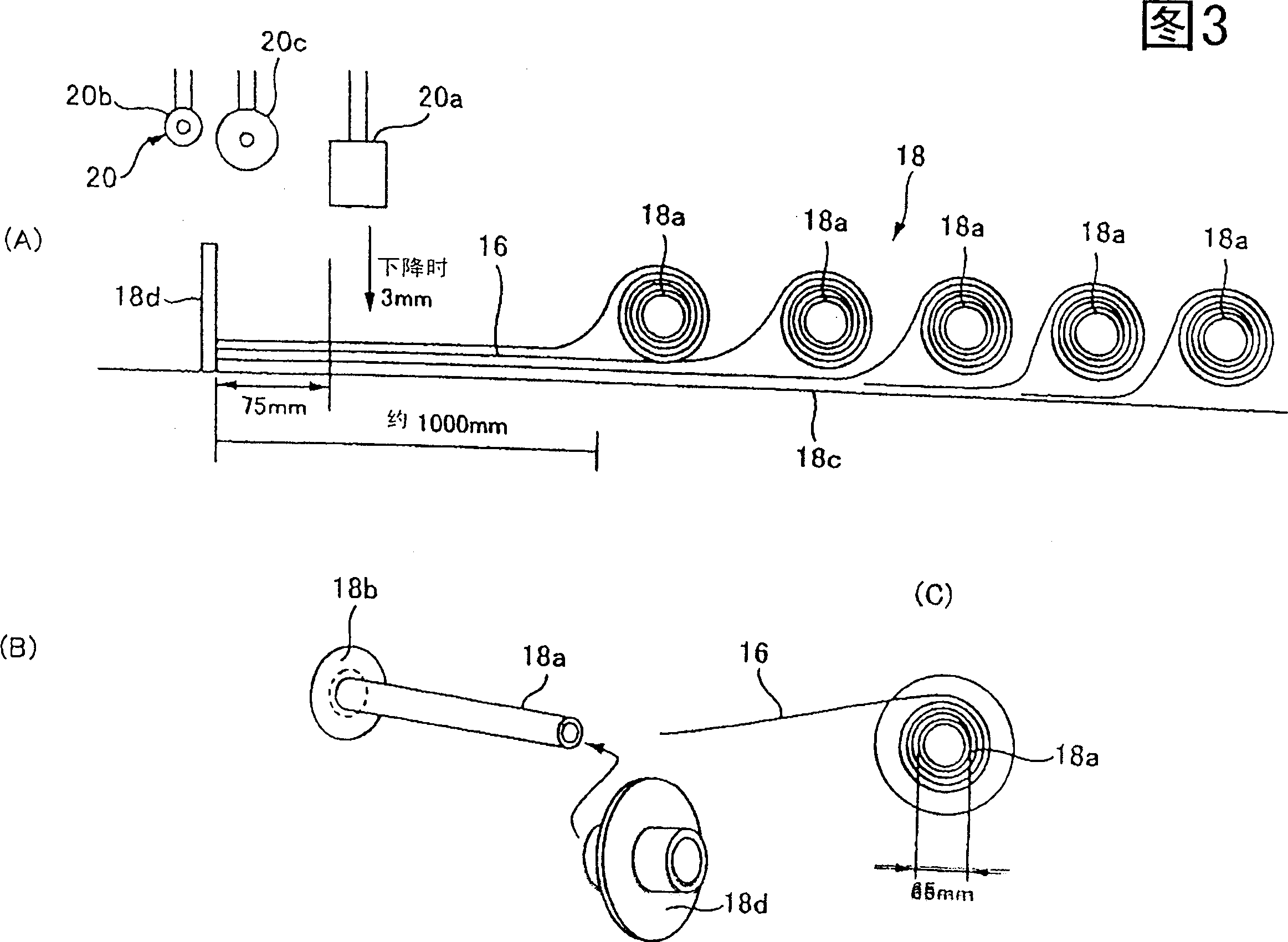

[0047] Hereinafter, the applicable embodiments of the present invention will be described in detail with reference to the drawings. 1 to 3 show Embodiment 1 of an interlayer inserting device related to the present invention.

[0048] The interlayer inserting device shown in the figure is used when the separator for the optical cable is wound in multiple layers around the outer circumference of a bobbin 10 driven by a traversing mechanism 14 .

[0049] The winder 10 has a cylindrical reel 10a and flanges 10b arranged in pairs at both ends of the reel 10a. The reel 10a is supported approximately horizontally and rotates in the direction indicated by the arrow in FIG. 1 , and its exterior is neatly wound There are multiple layers of separator 12 .

[0050] Plate-shaped interlayer materials 16 such as kraft paper or cardboard are sandwiched between upper and lower layers of the wound separator 12 . The traverse mechanism 14 is, for example, basically the same structure as that s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com