A polymer soft-pack lithium battery extrusion vacuum pumping system and a vacuum pumping process thereof

A soft-packed lithium battery and vacuum system technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of air leakage, insertion into the aluminum-plastic film, and shaking of the aluminum-plastic film, and increase the sealing effect. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures. It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict.

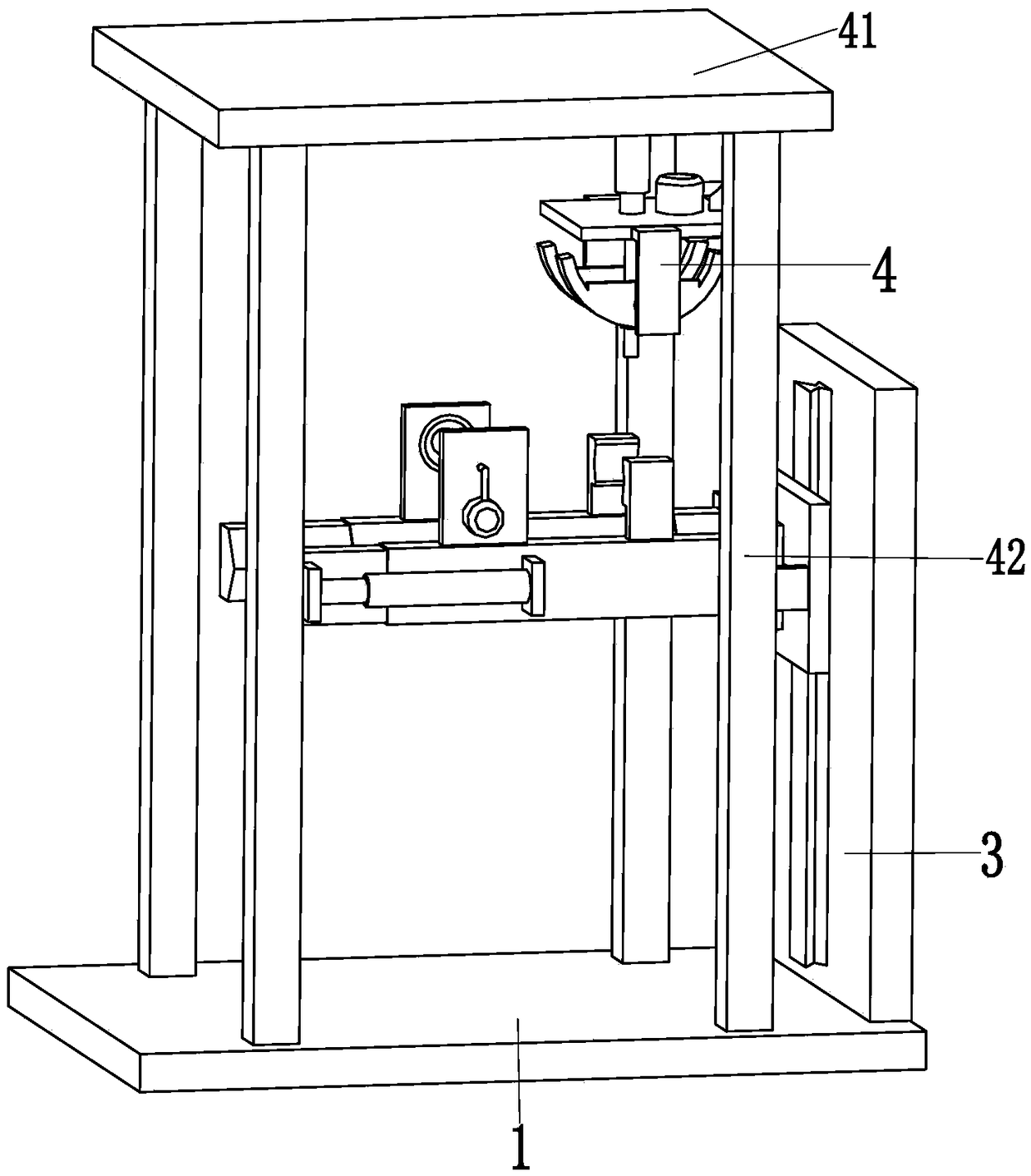

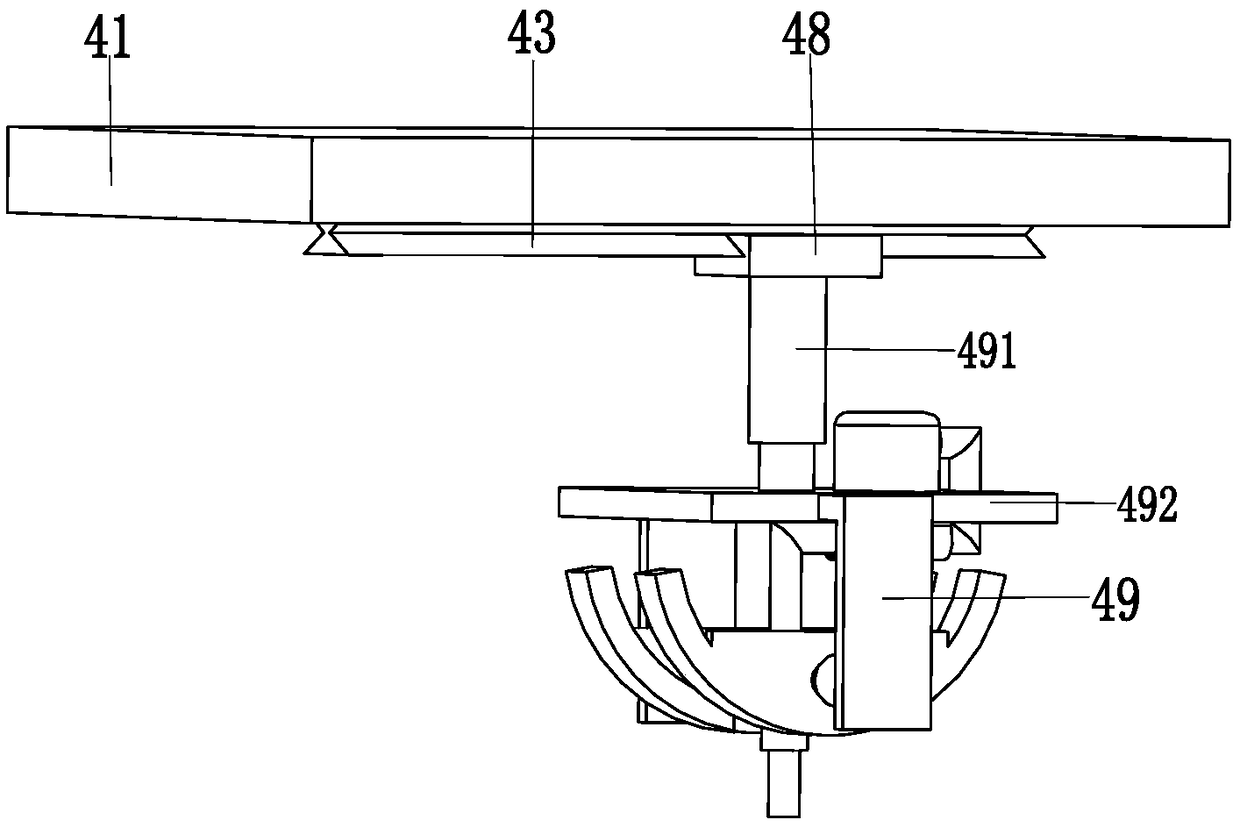

[0023] like Figure 1 to Figure 4 As shown, a polymer soft-packed lithium battery extrusion vacuum system includes a support base plate 1, a leveling device 3 and an extraction device 4, the leveling device 3 is installed on the top of the right end of the support base plate 1, and the extraction device 4 is mounted on top of the outer end of the support base plate 1 .

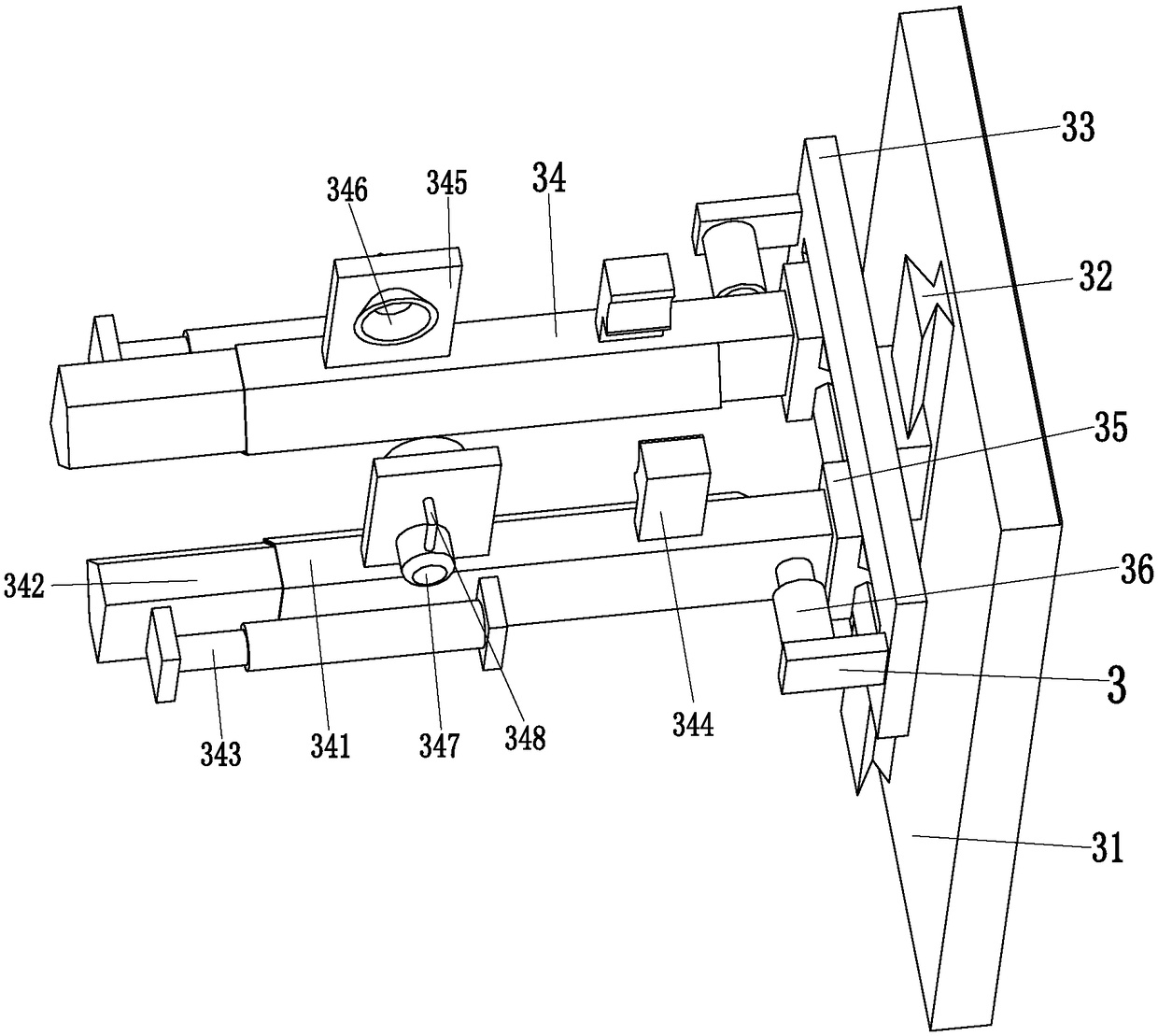

[0024]The smoothing device 3 includes a smoothing side plate 31, a smoothing electric slider 32, a smoothing support plate 33, a smoothing mechanism 34, a smoothing sliding plate 35 and a smoothing push rod 36. The smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com