General purpose combined harvester and thresher

A combine harvester and machine body technology, applied in the direction of harvesters, applications, cutters, etc., can solve the problems of body tilt left and right, complex conveying structure, weight increase, etc., to shorten the front and rear length, realize power consumption, and improve access Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

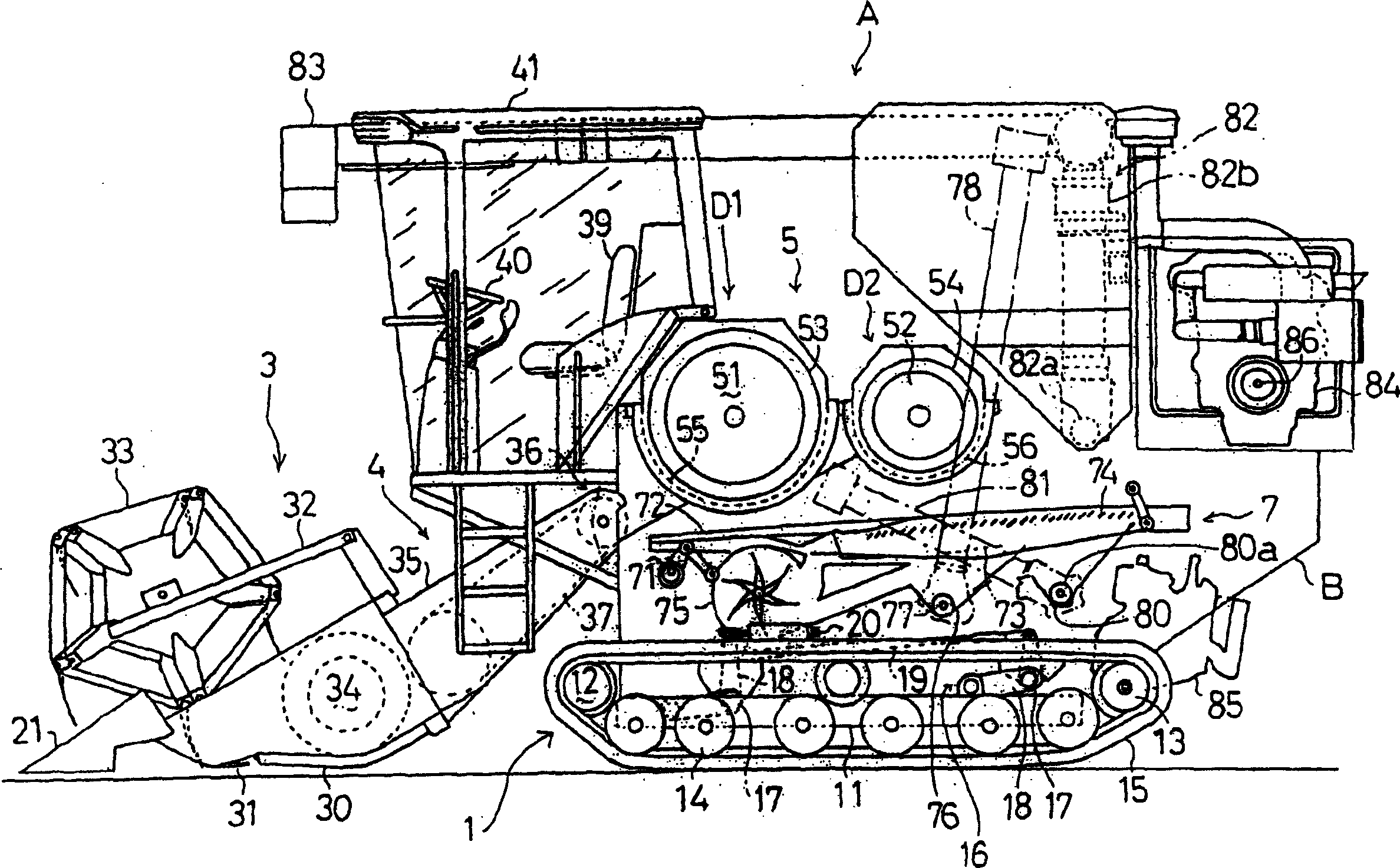

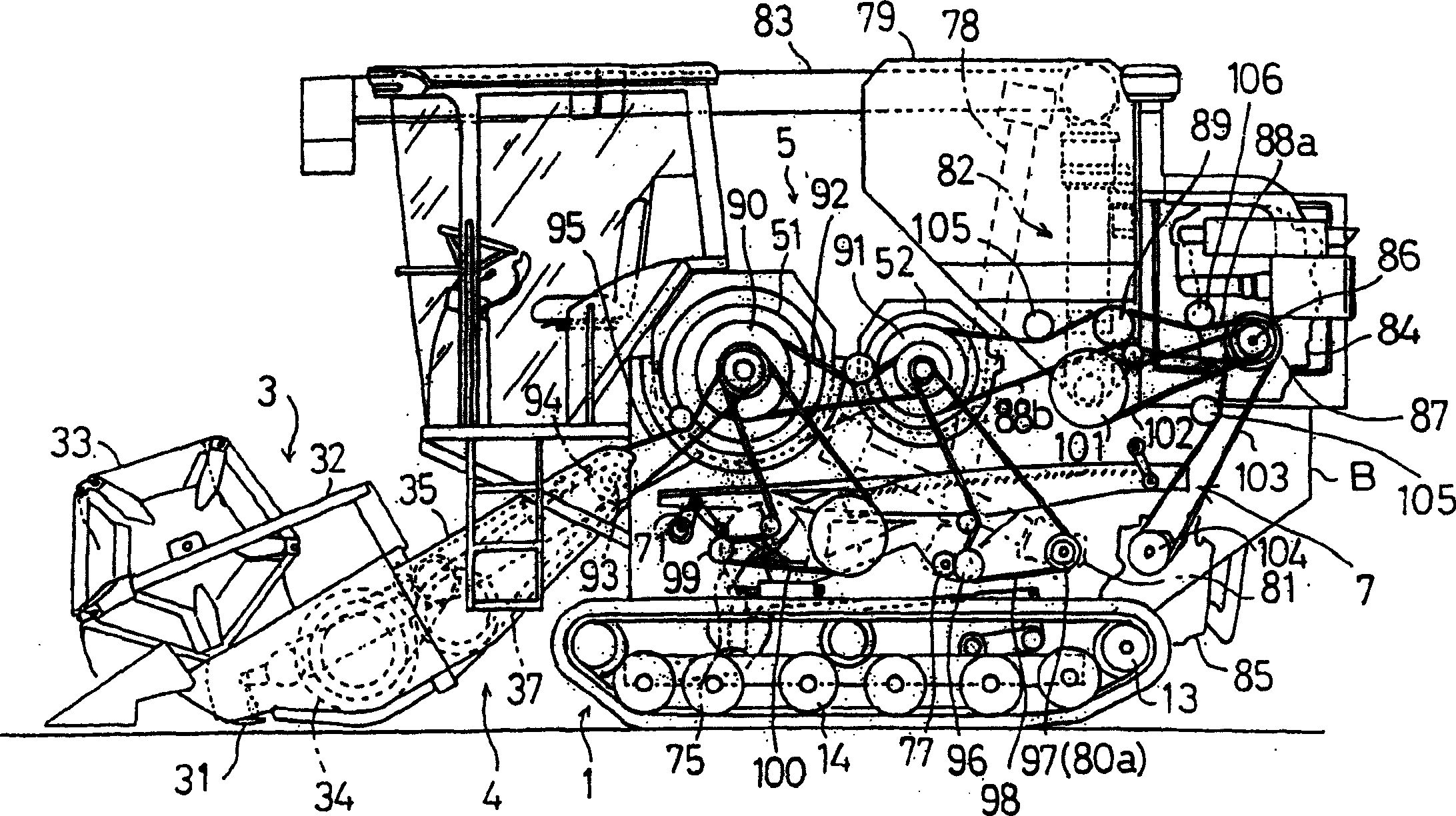

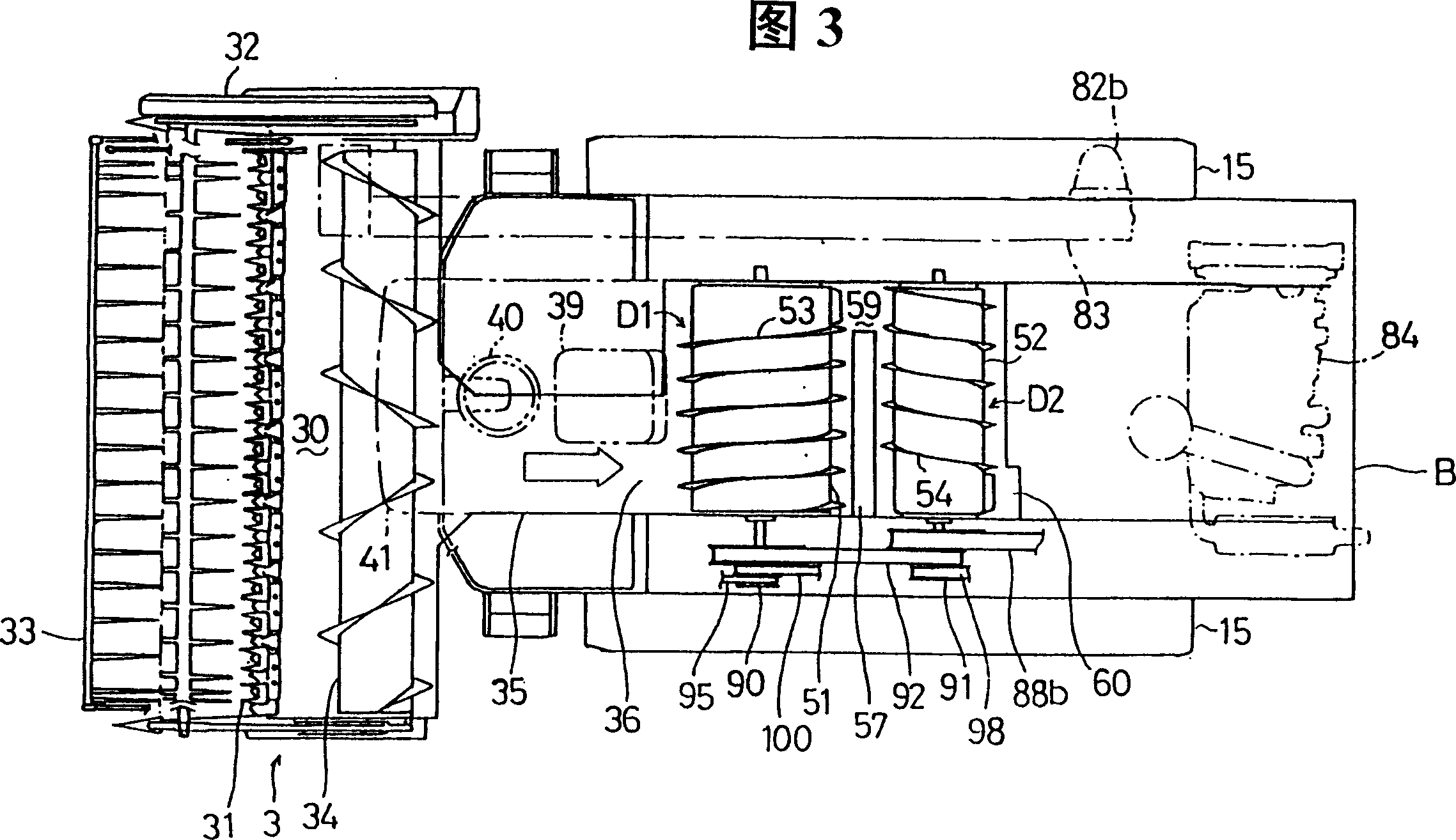

[0060] Figure 1 to Figure 11 The basic example of the general-purpose combine harvester A of this invention is shown. First, the general-purpose combine A of this basic implementation side is demonstrated. In addition, the left-right relationship is relative to the front-back direction of the body.

[0061] This general-purpose combine harvester A mounts the main machine B on the top of the running part 1, and the front of this main machine B protrudes and installs the reaping part 3 and the conveyance part 4 freely. As the transmission mechanism for the raising and lowering, for example, other examples will be described later. Figure 23 In , an embodiment is disclosed in which a lifting piston cylinder 140 of a hydraulic type or a pneumatic type is installed between the running part 1 and the feeder 35 .

[0062] walking part 1 such as figure 1 As shown, the driven wheel 12 and the driving force 13 are respectively supported on the front and rear ends of a pair of walki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com