Electric connector

A technology of electrical connectors and connecting parts, applied in the field of piercing electrical connectors, can solve the problems of reduced reliability of electrical connections, and achieve the effect of high reliability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

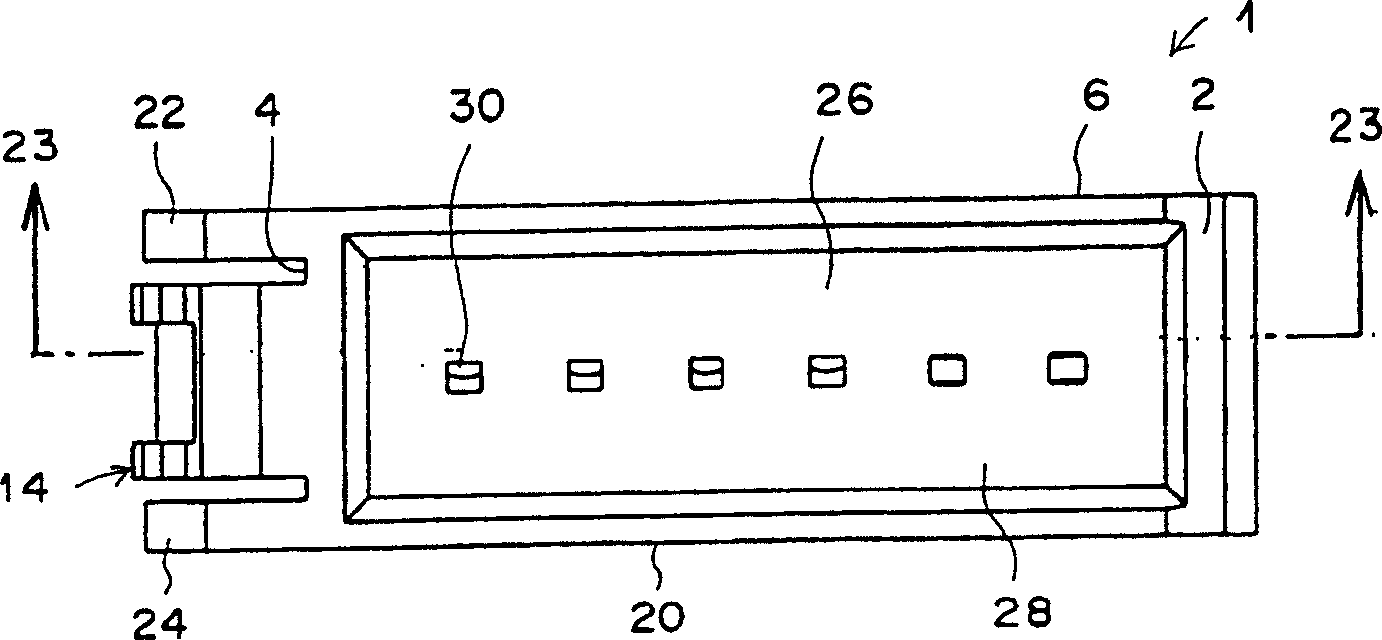

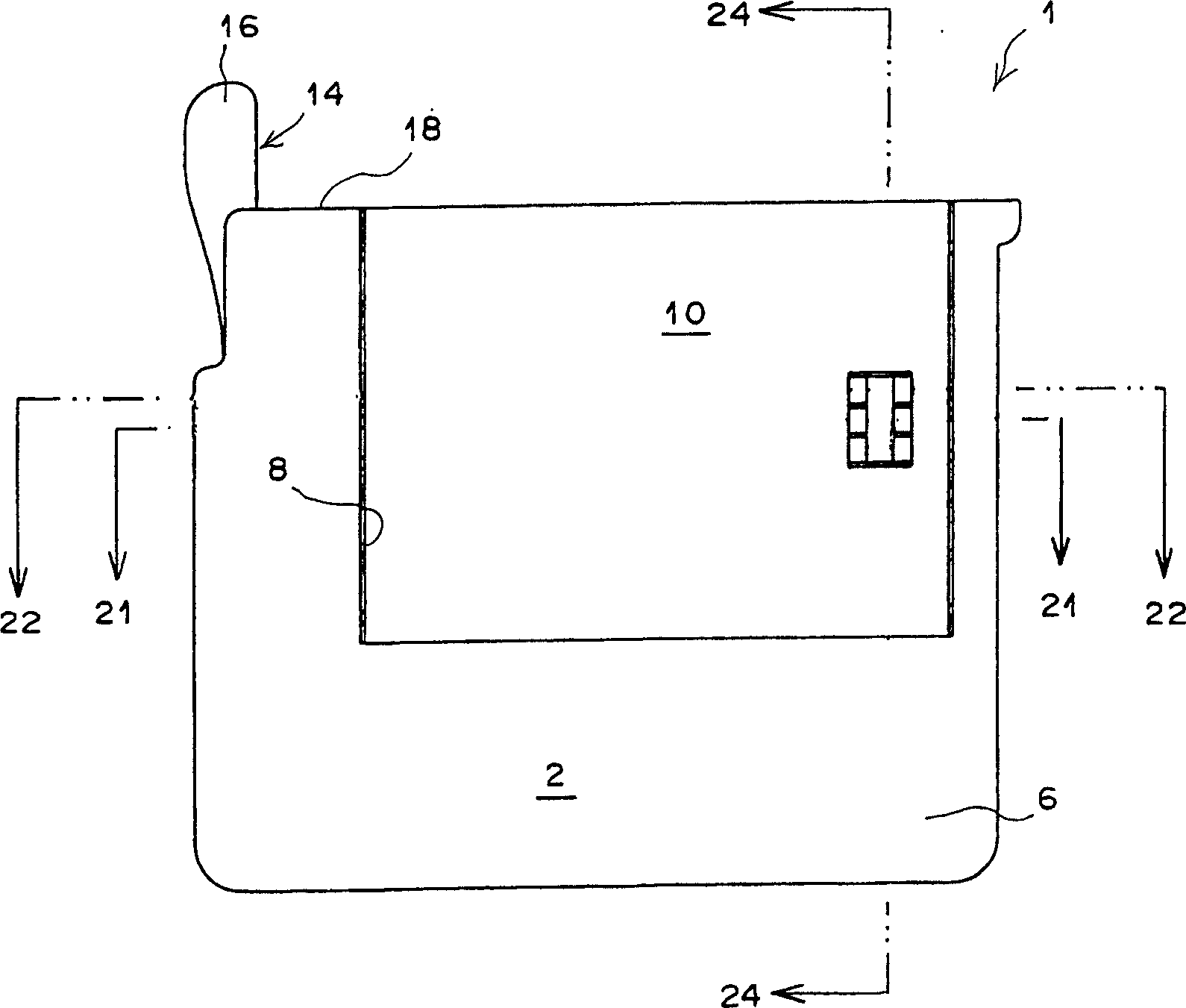

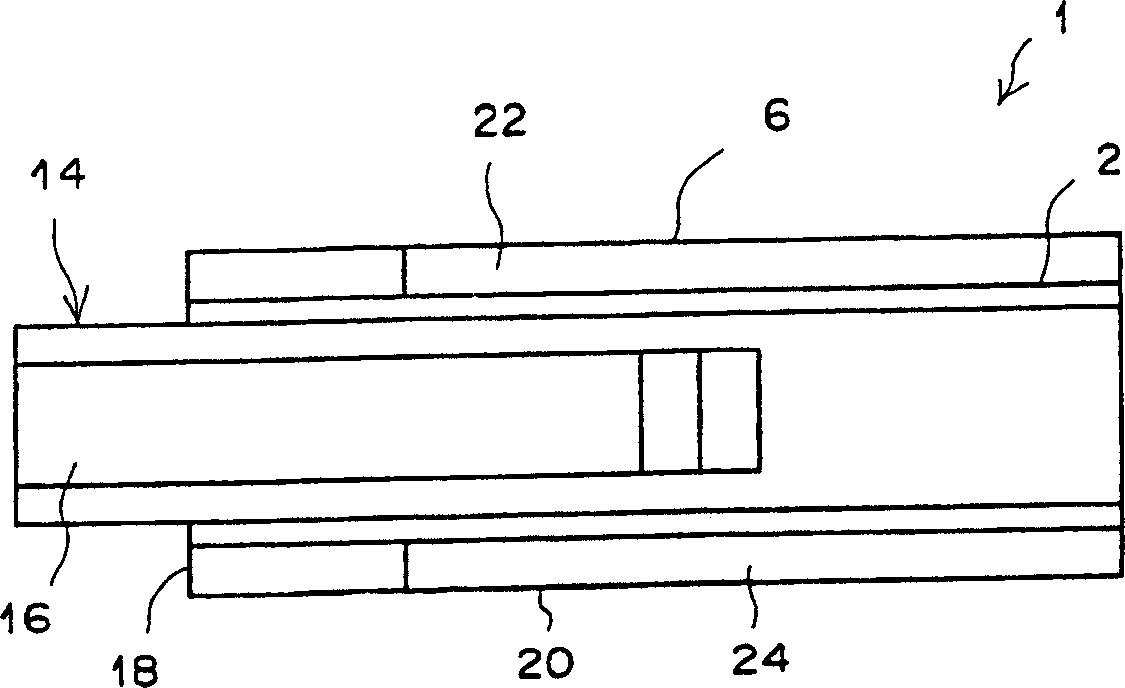

[0051] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 is a front view of the connector constituting the first embodiment of the present invention. figure 2 Yes figure 1 A floor plan of the connector shown. image 3 Yes figure 1 Left side view of the connector shown. Figure 4 is figure 1 Rear view of the connector shown. Refer below figure 1 Refer to Fig. 4 for description.

[0052] The housing 2 used in the connector 1 is substantially rectangular, and its plan view is close to a square. On the upper wall 6 of the housing 2, a rectangular groove 8 is formed, so that the groove 8 is separated from the housing 2 (in the figure 2 The bottom of the) near the center of the front part of the extension ( figure 2 ). The slot 8 is open towards the rear at the top. A cover housing 10 whose shape is complementary to the groove 8 is mounted inside the groove 8 . A circular hole 12 for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com