Fuel soft tube mounting structure of fuel jet engine

A technology for mounting structures and engines, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of unconfigurable, limited engine space, and reduced reliability of connections, so as to improve reliability, reduce the number of pipelines, Effect of improved connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described below with reference to the drawings.

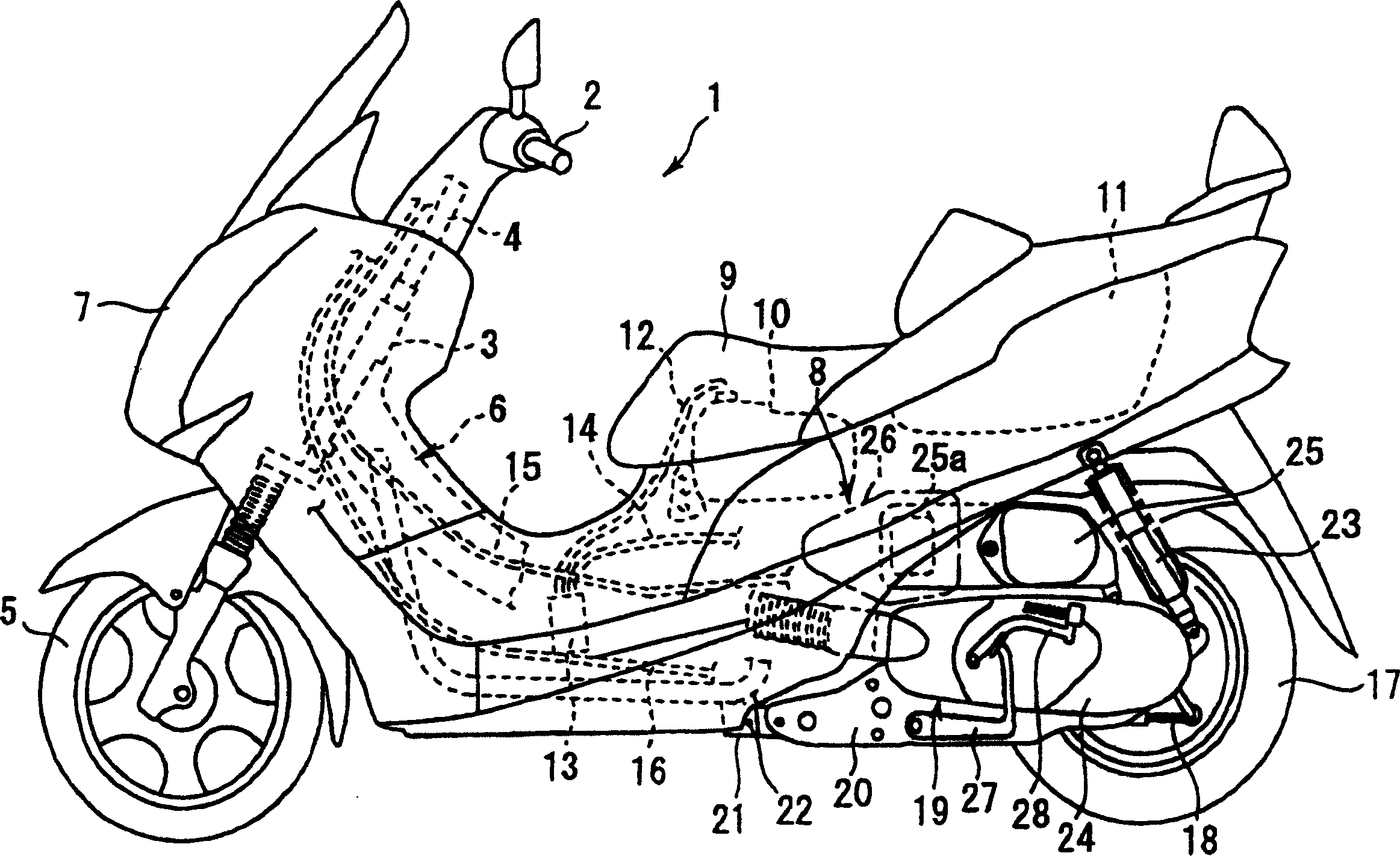

[0048] figure 1 It is an external view of a scooter suitable for the present invention.

[0049] The front part of the car body 1 has a handlebar 2, and the handlebar 2 is connected with the front wheel 5 through the steering shaft 4 inserted with the front pipe 3. The vehicle body frame 6 is combined with the head pipe 3 . The vehicle body frame 6 forms the overall frame structure of the vehicle. The front portion of the vehicle body is covered with a cowl 7 . From the outside of the vehicle body frame 6 , the vehicle body 1 is covered by a vehicle body cover 8 . Car body center is provided with vehicle seat 9, and its underside is provided with fuel tank 10, and its rear is provided with hood box (loading) 11. The fuel tank 10 supplies fuel to a nozzle (not shown) through a fuel hose (not shown). One end of a breather hose 12 is connected to the upper portion of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com