Runway type pneumatic drilling machine

A pneumatic drilling rig, runway-type technology, which is applied to rotary drilling rigs, impact drilling, rotary drilling and other directions, can solve the problems of inability to fully control the drilling rig, difficulty in constructing discharge holes, and the need for many personnel. Improve the ability to fight against unexpected risks, ensure safety and stability, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

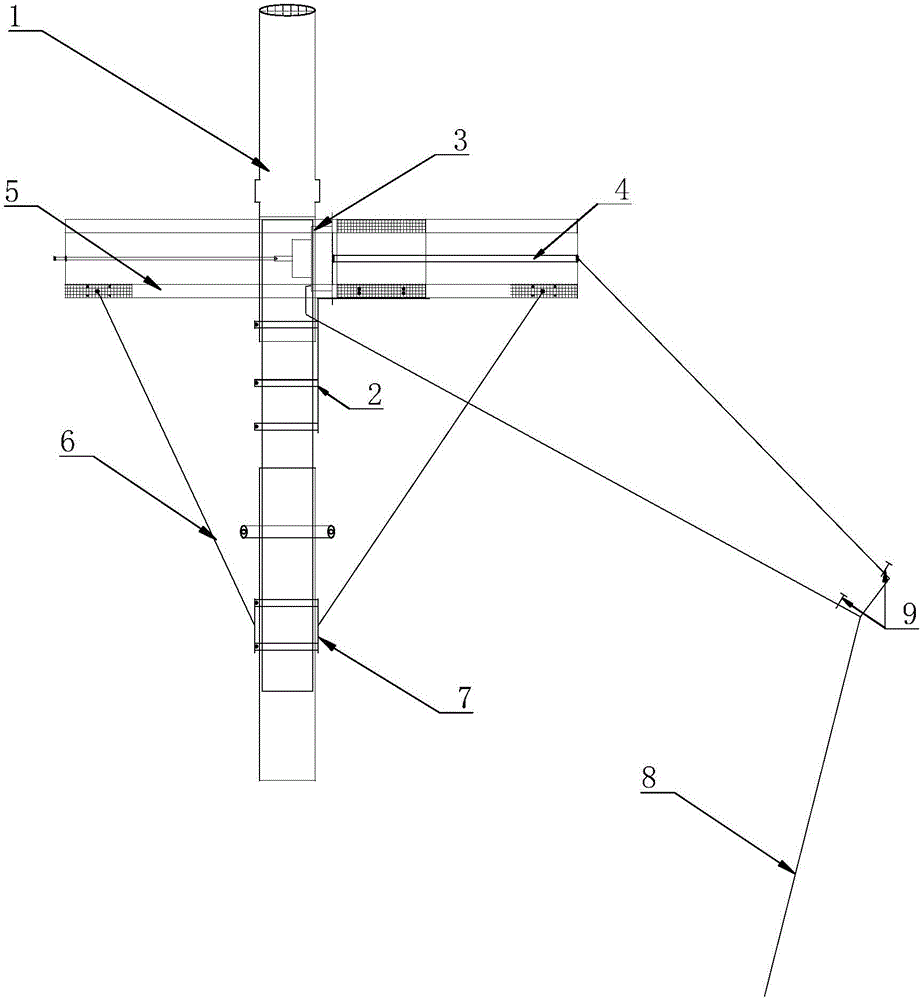

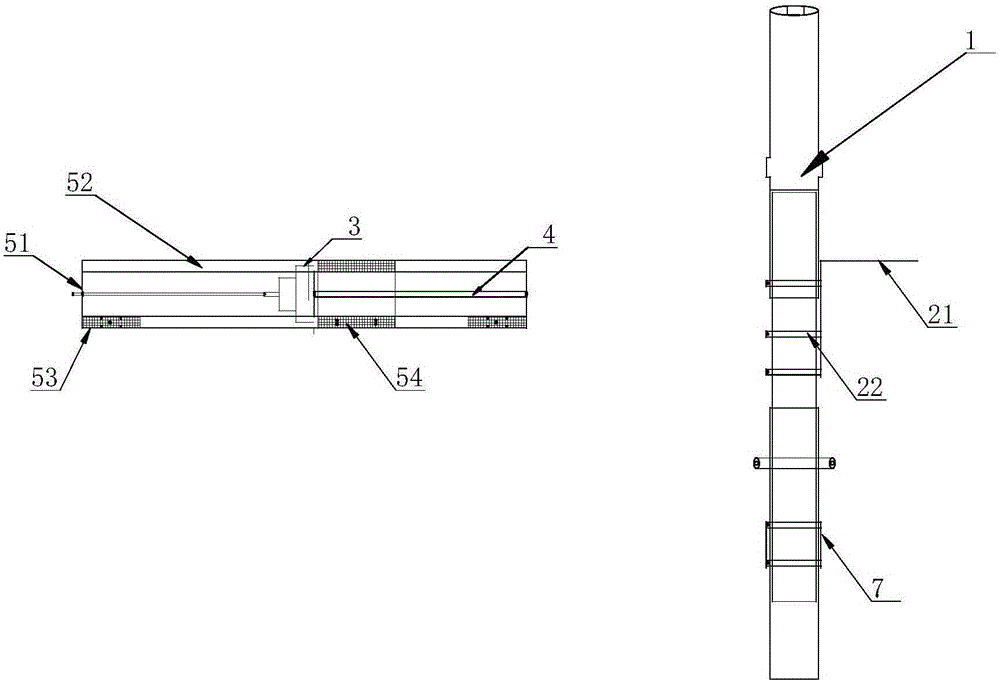

[0025] figure 1 It is a structural diagram of Embodiment 1 of the present invention, figure 2 is the invention figure 1 A partial disassembly schematic.

[0026] In the figure, the meanings of each reference sign are as follows: 1. Single hydraulic prop; 2. Second fixing device; 21. Arc plate; 22. Second fixing plate; 3. Pneumatic drilling machine; 4. Air pressure type Propelling cylinder; 5. Rig runway; 51. End baffle; 52. Guide column; 53. Support rod fixing device; 54. First fixing plate; 6. Support rod; 7. Third fixing device; 8. Main pipe ; 9. Ball globe valve.

[0027] In the figure, the meanings of each reference sign are as follows: 1. Single hydraulic prop 1; 2. Second fixing device 2; 21. Arc piece 21; 22. Second fixing plate 22; 3. Pneumatic drilling machine 3; 4. Air pressure propulsion cylinder 4; 5. Rig runway 5; 51. End baffle 51; 52. Guide column 52; 53. Support rod 6 fixing device 53; 54. First fixed plate 54; 6. Support rod 6; 7. The third fixing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com