Batch polycondensation method and rotating disc reactor therefor

A reactor and polycondensation technology, applied in the field of discontinuous polycondensation and its agitated reactors, can solve problems such as limiting polycondensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

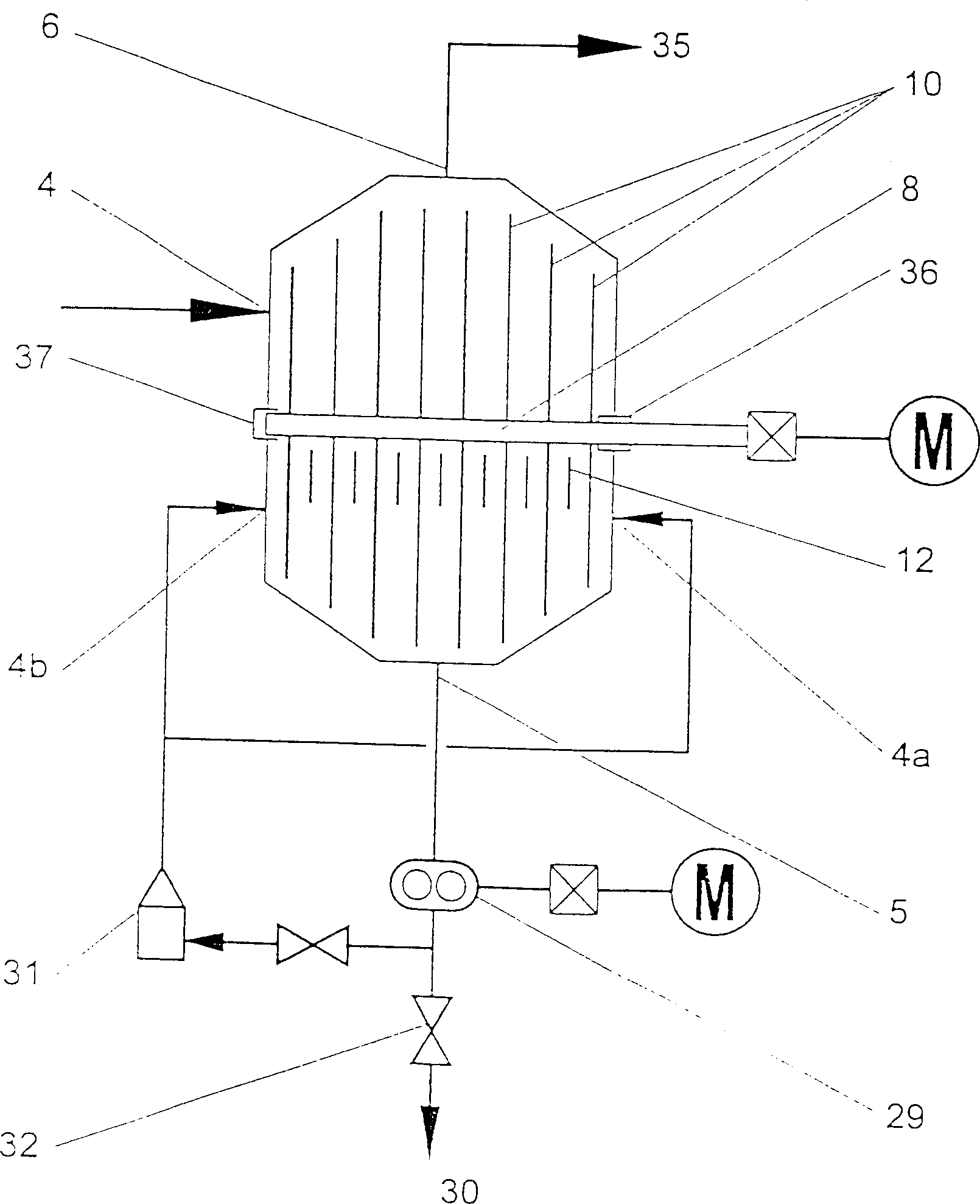

[0119] Starting from 212 kg of terephthalic acid (TPA) and 90 kg of ethylene glycol (EG), about 245 kg of PET is regularly produced as a melt in a typical plant in a discontinuous esterification and polycondensation process, and processed to obtain pellets, deduction of 2 to a starting loss of 2.5%.

[0120]Precondensation and polycondensation were done in the presence of 180 ppm Sb and 10 ppm P, which had been supplied to the process as antimony triacetate in ethanol solution or as phosphoric acid.

[0121] The temperature and pressure of the precondensation ended at 276°C and 60 mbar; prepolymer sampling showed a TPA conversion of 98.6% and an intrinsic viscosity IV in the range of 0.165 to 0.17 dl / g.

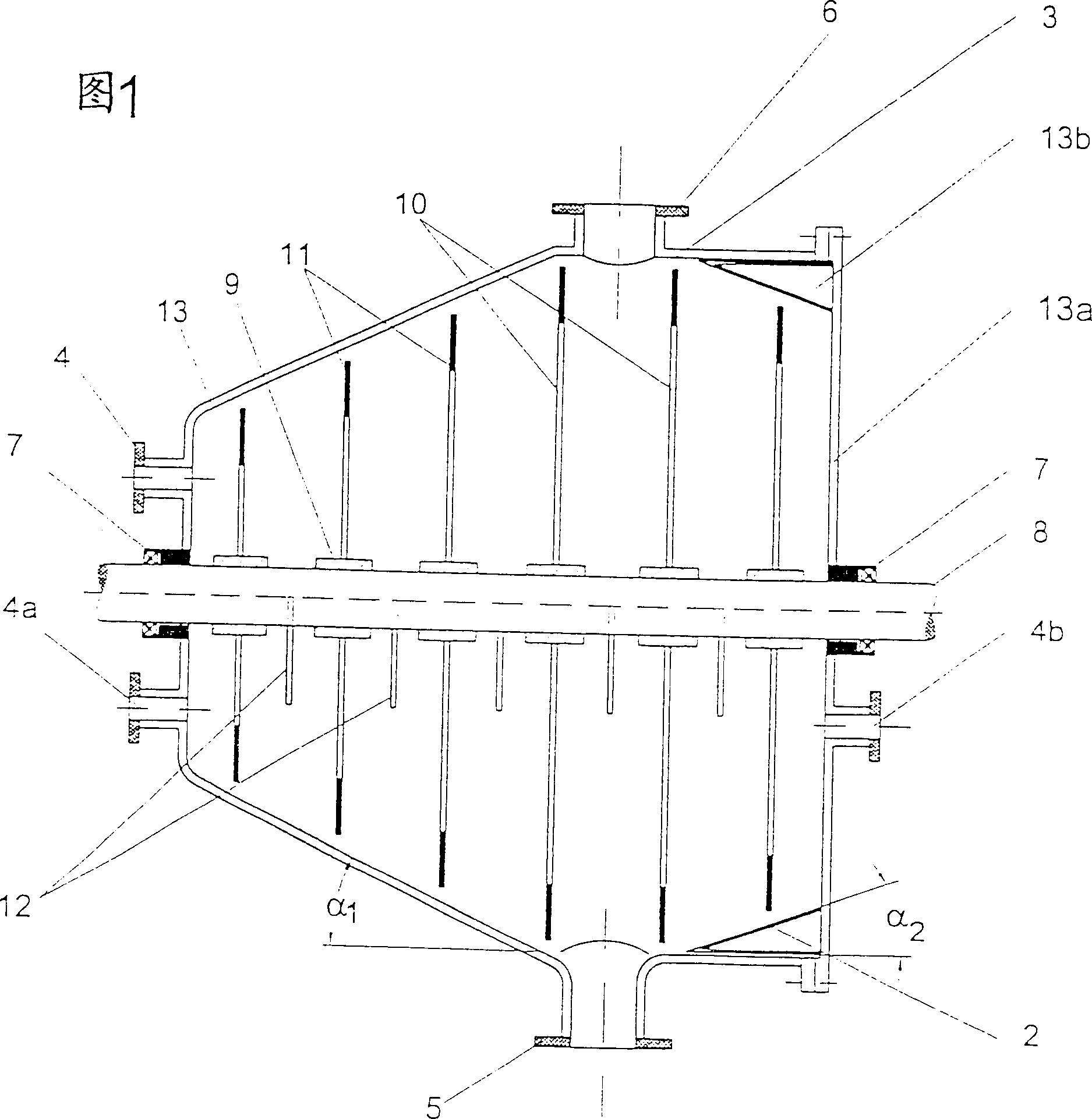

[0122] Within about 15 minutes, the prepolymer was transferred by means of nitrogen pressure into an agitated annular disk autoclave type B according to Table 2. After the previous batch had been granulated and the discharge valve closed, the autoclave was provided to accept ...

example 2

[0137] Similar to the plant in Example 1, in a typical plant starting from 180 kg of terephthalic acid (TPA) and 107 kg of 1,3-propanediol (PDO), approximately 222 kg of polypropylene terephthalate is produced intermittently as a melt (PTT), 85 ppm titanium was added in the form of butyl titanate, and granulation was performed with a yield of about 95%.

[0138] By means of esterification, the precondensation was carried out at a final temperature of 256° C. and a final pressure of 50 mbar. The precondensate showed a TPA conversion of about 99.9% and an intrinsic viscosity IV = about 0.17 dl / g.

[0139] Using speed control and pumping similar to Example 2 for external recirculation of the product, the polycondensation was completed at a vacuum of about 1.0 mbar after 60 minutes and a final vacuum of 0.5 mbar after about 150 minutes. Heating at a temperature of 254°C with constant HTM. The polycondensation was terminated after about 156 minutes, the product temperature rose t...

example 3

[0143] In the esterification transfer and polycondensation process of a typical plant, 250 kg of dimethyl terephthalate (DMT) and 151 kg of 1,4-butanediol (BDO) and 45 ppm Ti as tetraisopropyl titanate were used. 283 kg of polybutylene terephthalate (PBT) were produced and pelletized.

[0144] The precondensation was terminated at 236° C. with a vacuum of 80 mbar. For further polycondensation, the precondensate was supplied to a stirred reactor type A according to Table 2 and polycondensed to a DMT conversion of 99.5% and a solution viscosity IV=0.16 dl / g.

[0145] The main reaction parameters are:

[0146] - polycondensation time is 170 minutes,

[0147] - a constant rotation speed of 6.7 rpm for about 100 minutes, a linear decrease in rotation speed from 6.7 to 1.2 rpm in another hour, and a constant rotation speed of 1.0 rpm thereafter,

[0148] - a vacuum of 1.5 mbar after 60 minutes and a final vacuum of 1.2 mbar after about 150 minutes,

[0149] - product temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com