Methods and apparatus for reducing viberations induced within fan assemblies

A technology for fan components and equipment, applied in mechanical equipment, pump components, machines/engines, etc., can solve problems such as expensive, complex, and damping system failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

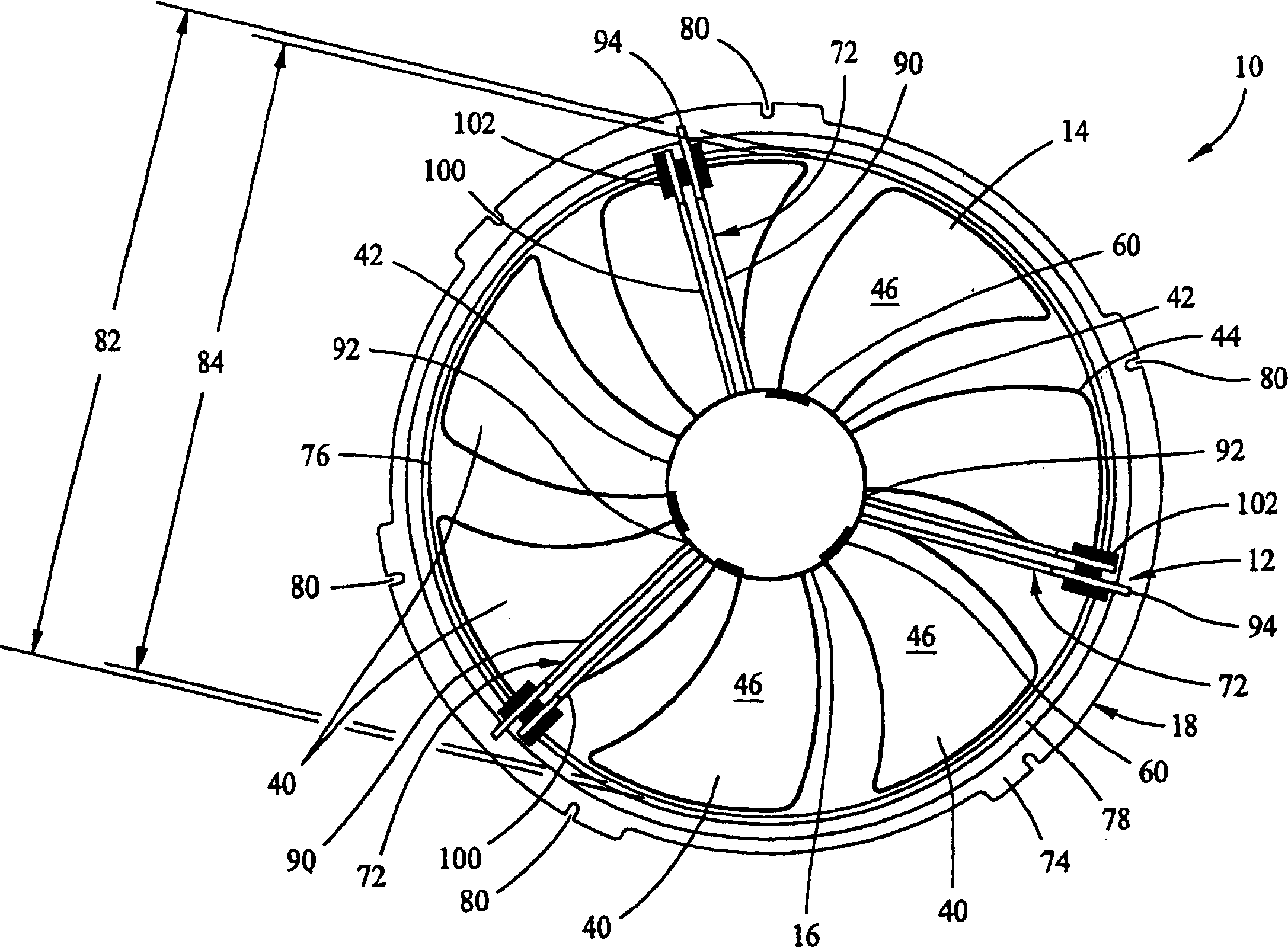

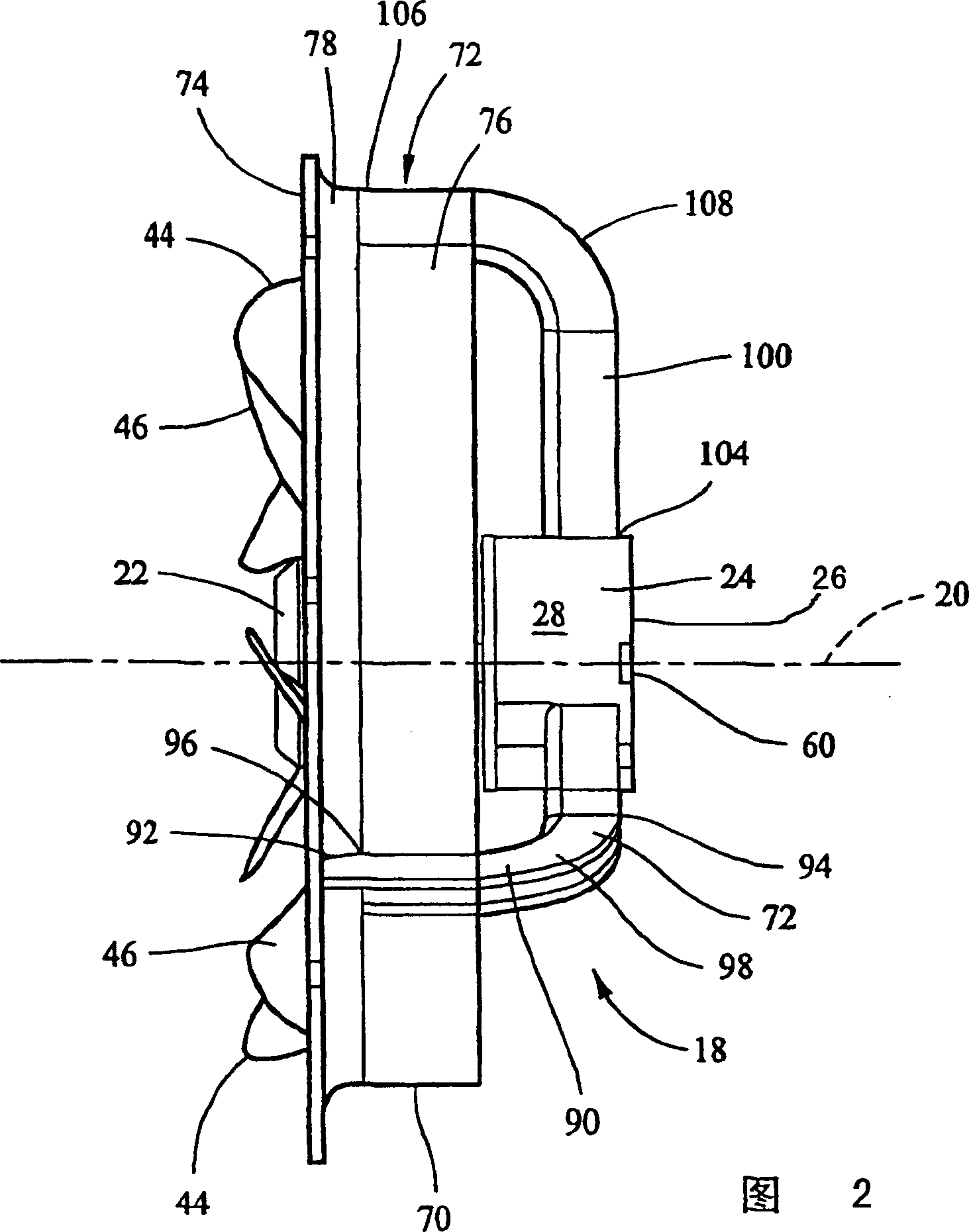

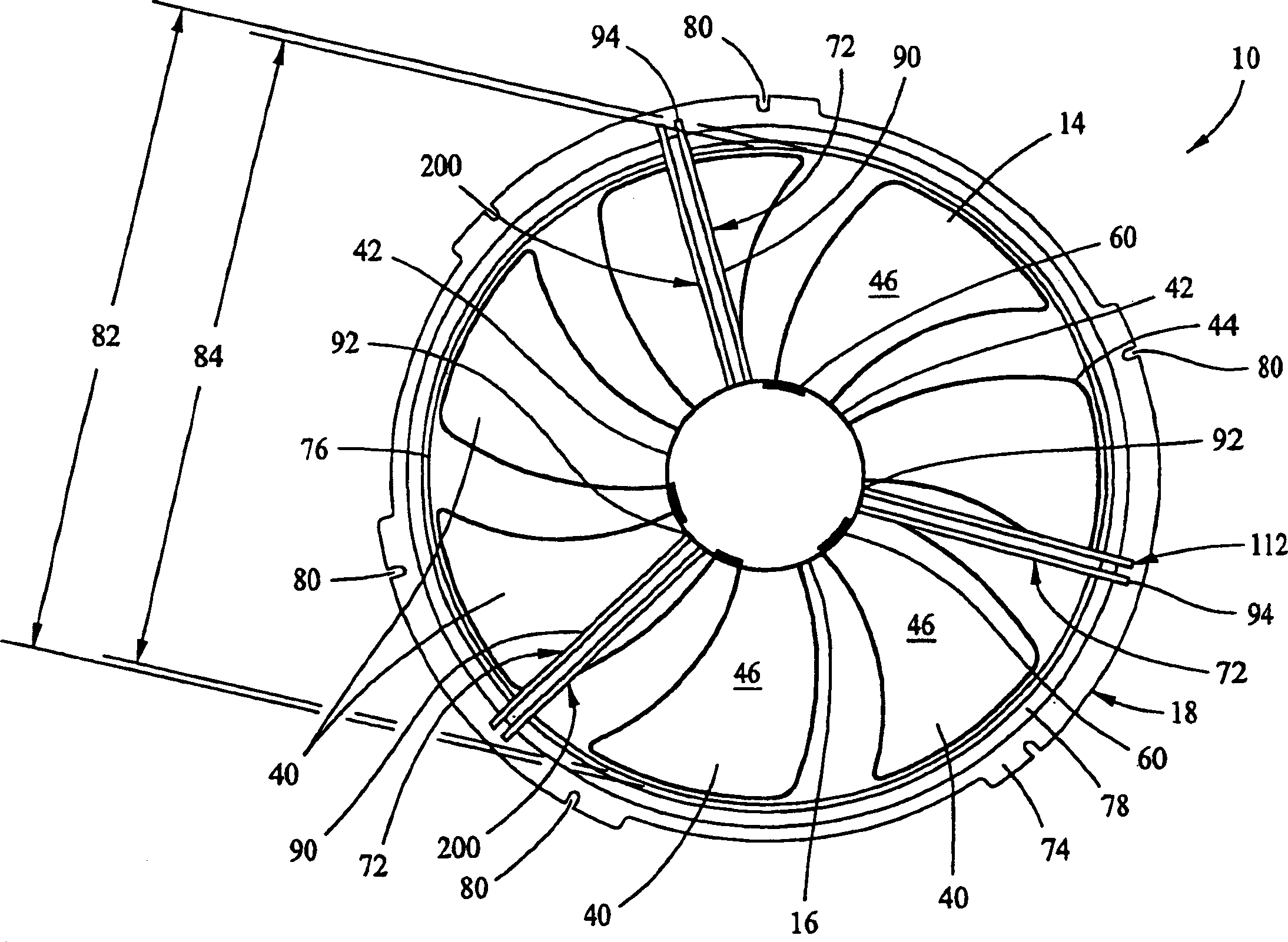

[0014] figure 1 and 2 are rear and side views, respectively, of the fan assembly 10 including the vibration damping system 12 . Fan assembly 10 includes a motor (not shown), a control unit (not shown), a fan 14 , a motor housing 16 , and a shield assembly 18 . The motor and fan control device is disposed inside the motor housing 16 and controls power to the fan 14 and controls rotation of the fan 14 about the axis of rotation 20 .

[0015] The motor housing 16 includes a rotating portion 22 and a stationary or shielding cup portion 24 . Stationary portion 24 is generally cylindrical and includes top 26, side walls 28, and a bottom flange (not shown). Side walls 28 extend substantially vertically from top 26 to the bottom flange. The bottom flange extends radially outwardly from the side wall 28 and enables the stationary portion 24 to be in sealing and rotatable contact with the rotating portion 22 .

[0016] The fan 14 is mounted to the rotating portion 22 and includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com