Textile fiber with conductive and magnetic conductive function and its preparing method

A technology of textile fibers, electrical conductivity and magnetic conductivity, which is applied in the field of preparing textile fiber materials with dual functions, and can solve problems such as electromagnetic leakage and harm of electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

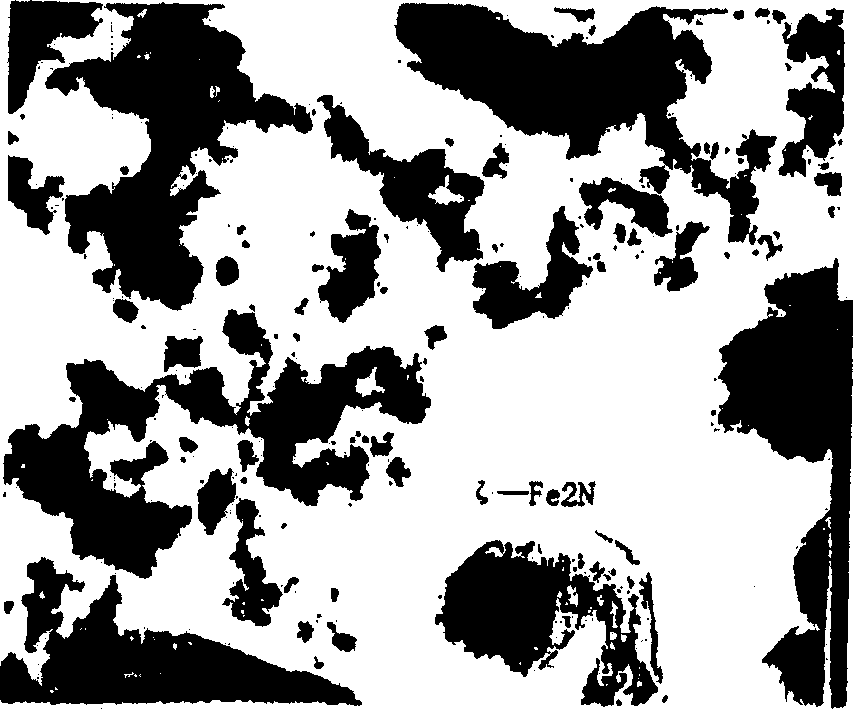

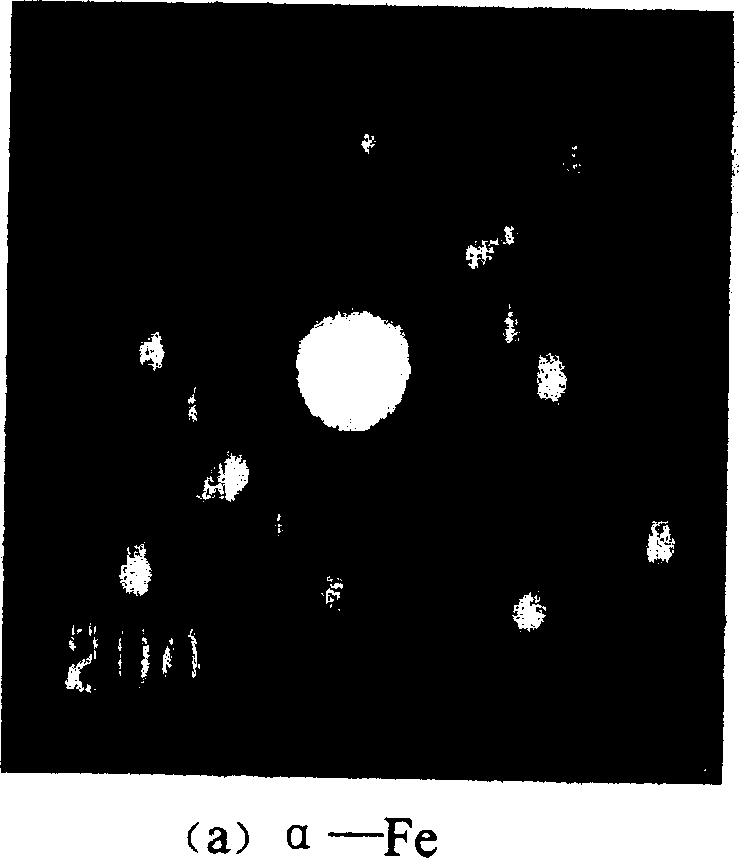

[0024] Method 1: According to the composition and preparation method of the fiber textile material with conductive and magnetic properties and dual-function functions, we have prepared three batches of fiber textile materials with double-function functions, and the preparation process is based on carbonyl thermal decomposition method. Production Parcel Fe 3 o 4 ζ—Fe 2N·α-Fe double-complex functional nano powder, then put the mixture into a high-speed mixer and stir it, and then melt it in the reactor after the material is mixed evenly. The treatment process is shown in Table 1, and then spin-oiling -The winding-stretching process adopts the method of the existing technology, and the twin-screw extruder equipment is used to process and produce semi-finished products, and the materials are processed into test products, and then the precision electronic device workshop and the confidential room are processed. Aspects of the application tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com