Electric compressor

An electric compressor and electric technology, applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve problems such as high-level electromagnetic noise, increased loss, unbalanced rotating magnetic field, etc., to reduce stator vibration and improve Rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the compressor of the present invention will be described with reference to the drawings. In addition, the same structure as the prior art is attached with the same code|symbol, and detailed description is abbreviate|omitted.

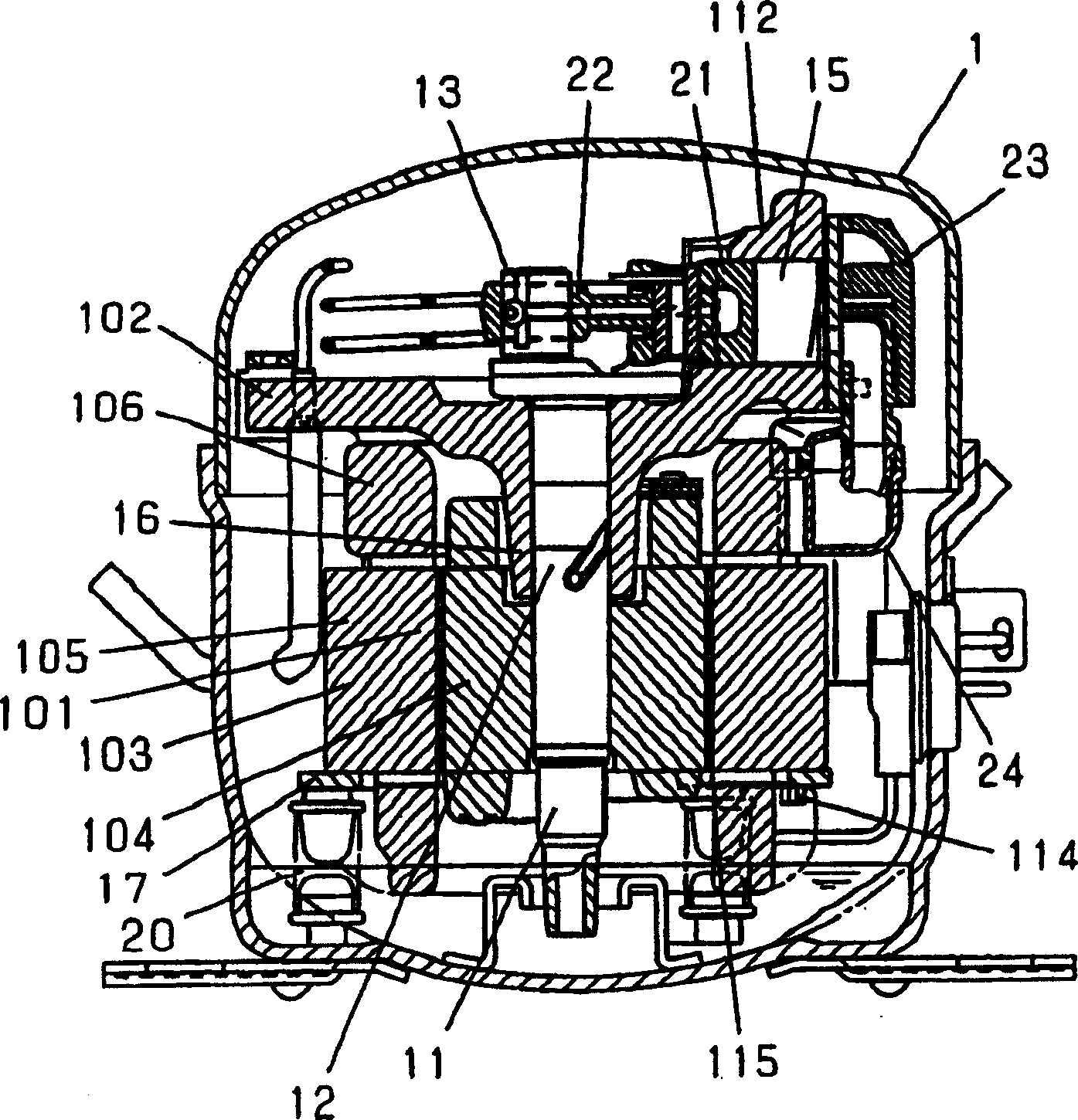

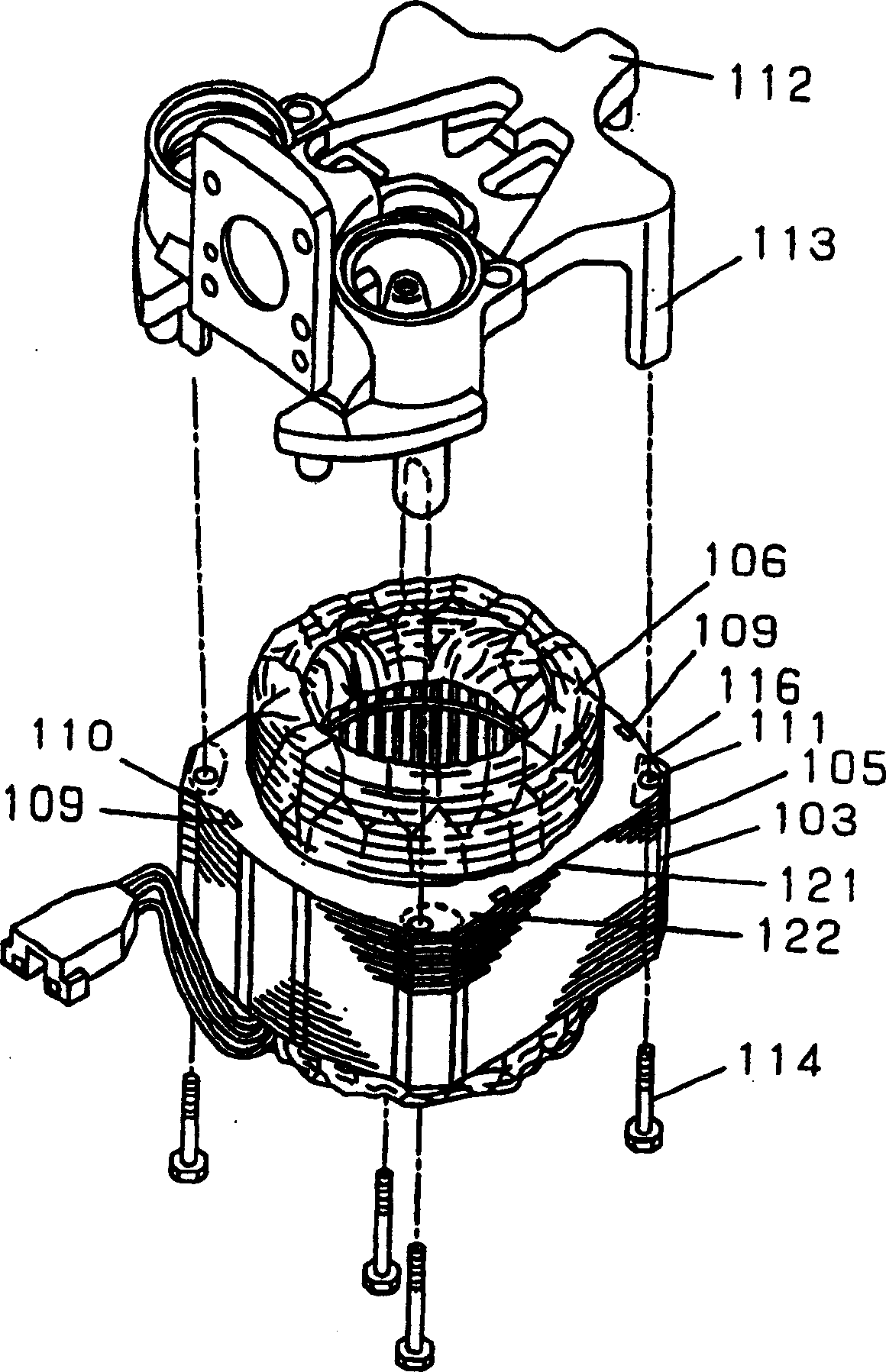

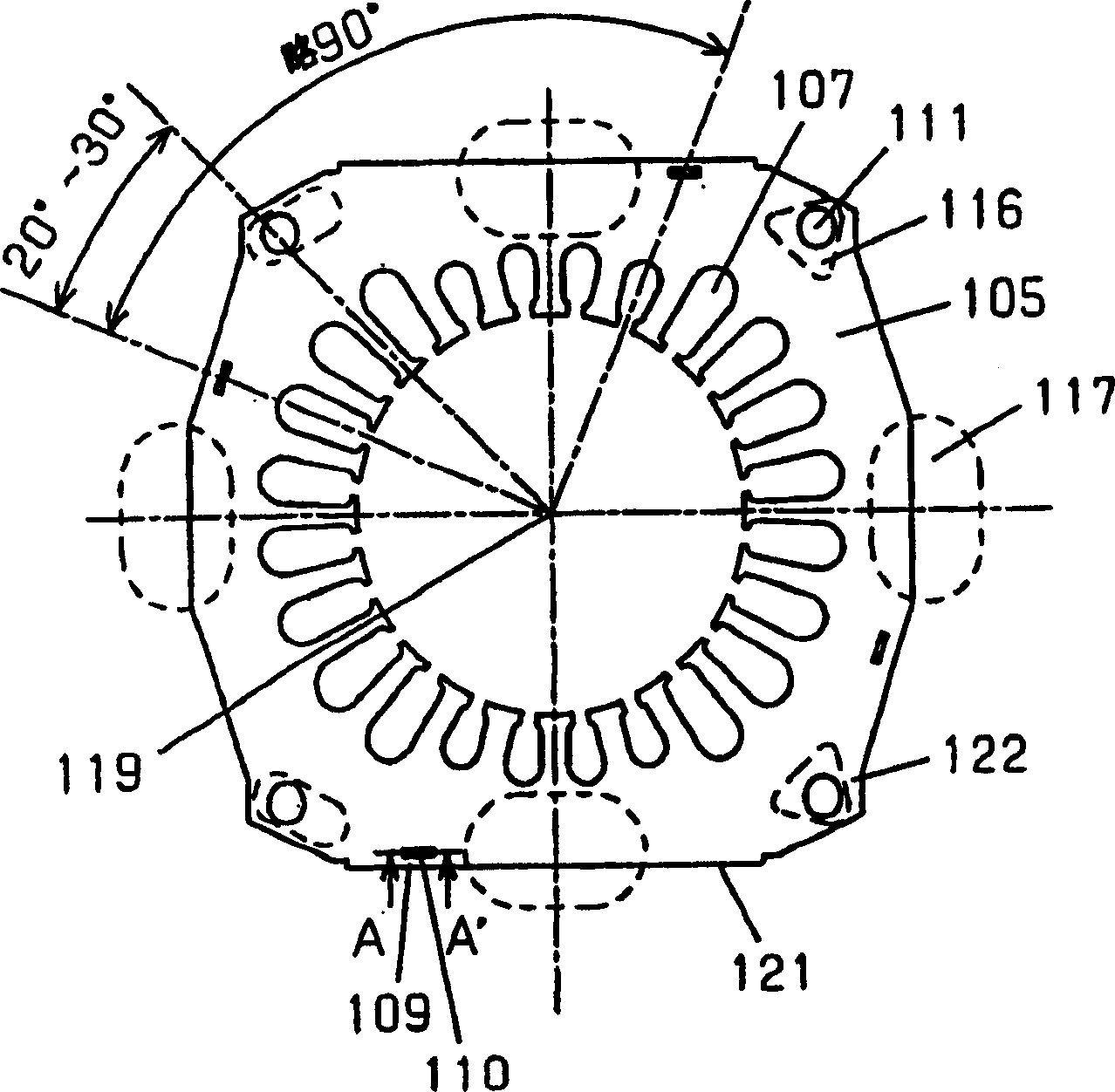

[0031] figure 1 It is a longitudinal sectional view of the first embodiment of the electric compressor of the present invention, figure 2 is an exploded perspective view of an end block, stator and penetrating bolts of the same embodiment, image 3 is a top view of the stator core of the same embodiment, Figure 4 for image 3 Sectional view at A-A' of . in addition, Figure 5 It is a plan view of the stator core of the electric compressor 2nd Embodiment of this invention.

[0032] Figure 1 to Figure 5 In the container 1, a motor assembly 101 and a compression assembly 102 are accommodated, and the motor assembly 101 is composed of a stator 103 and a rotor 104 . The stator 103 is composed of a stator core 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com