Luminous device and its producing method

A technology of light-emitting devices and production methods, which is applied in the field of light-emitting devices with high luminous efficiency, and can solve the problems of no improvement proposed and no consideration of light loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

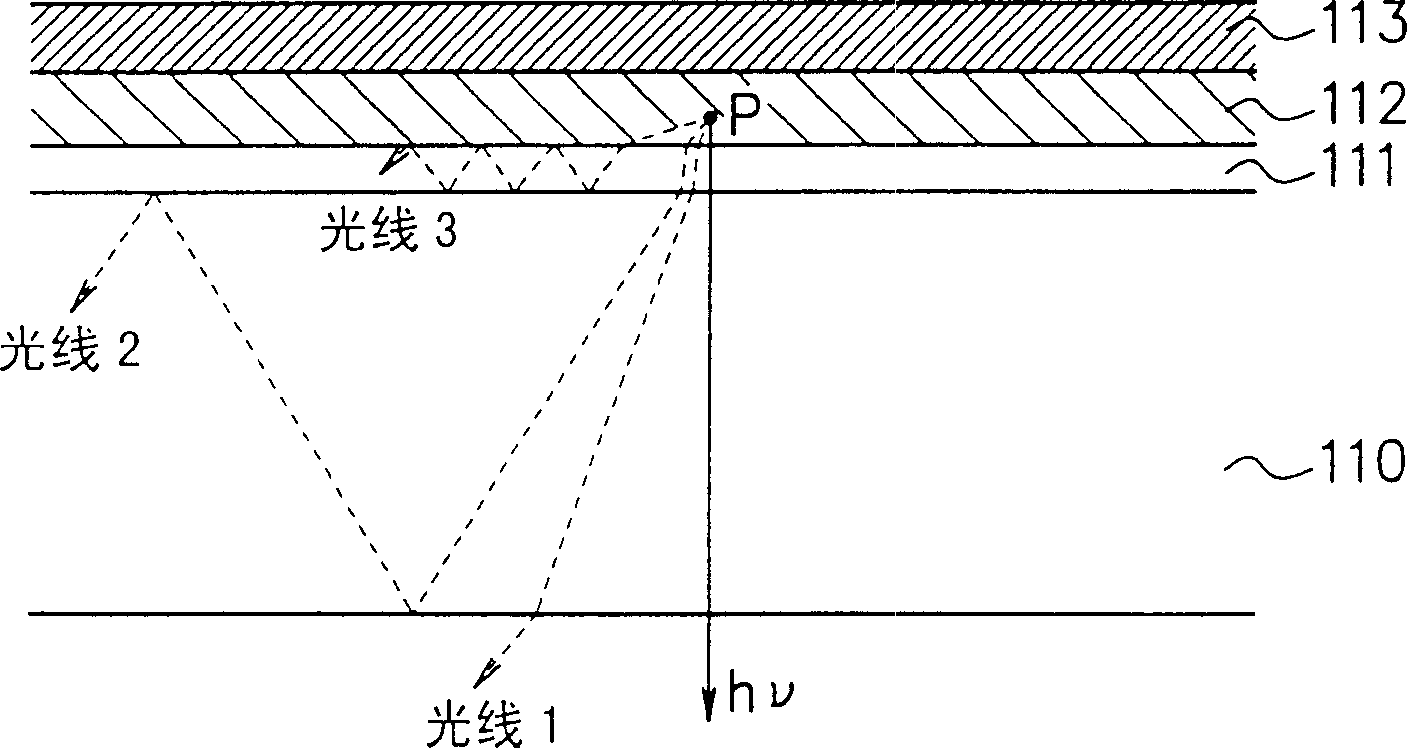

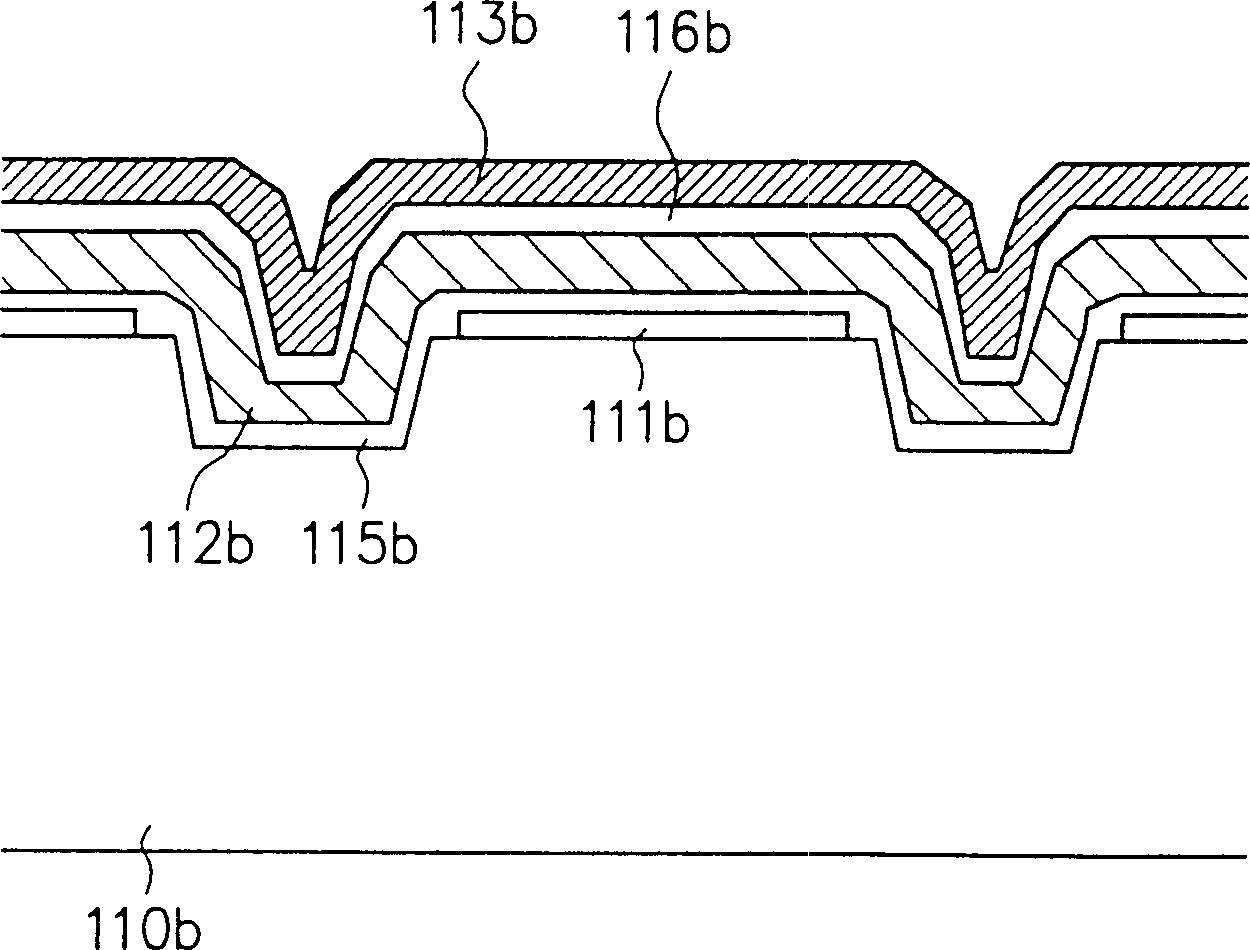

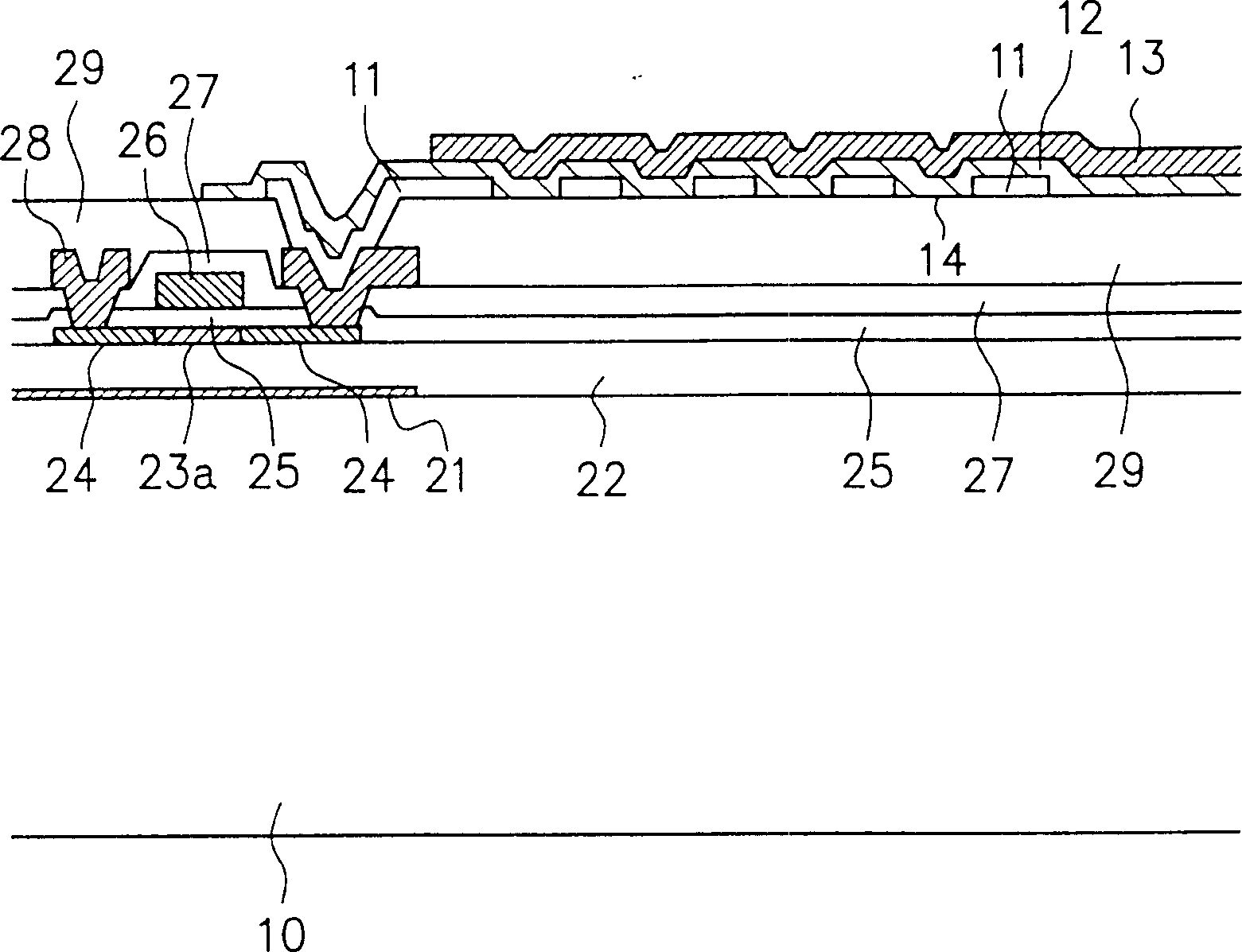

[0097] image 3 One example of the main components of the light emitting device according to the first embodiment and its structure is shown. The light emitting device includes a light emitting part formed on a transparent substrate 10 by a multi-layer cladding formation process described below, and a thin film transistor (TFT) circuit for driving the light emitting part.

[0098] Such as image 3 As shown, the light emitting member is formed by interposing a light emitting material layer 12 made of an organic electroluminescent (EL) material between a transparent electrode 11 and a reflective electrode 13 . Light is emitted from the layer of luminescent material 12 sandwiched between these two electrodes. A part of the transparent electrode 11 is connected to a source / drain 28 . The reflective electrode 13 and the outer lead (in image 3 not shown) c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com