Method for pouring and assembling light wallboard

A technology of lightweight wall panel and installation method, which is applied to the preparation of walls, formwork/formwork/work frame, and building components on site, etc., can solve the problems of high installation cost, low degree of mechanization, and complicated construction procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

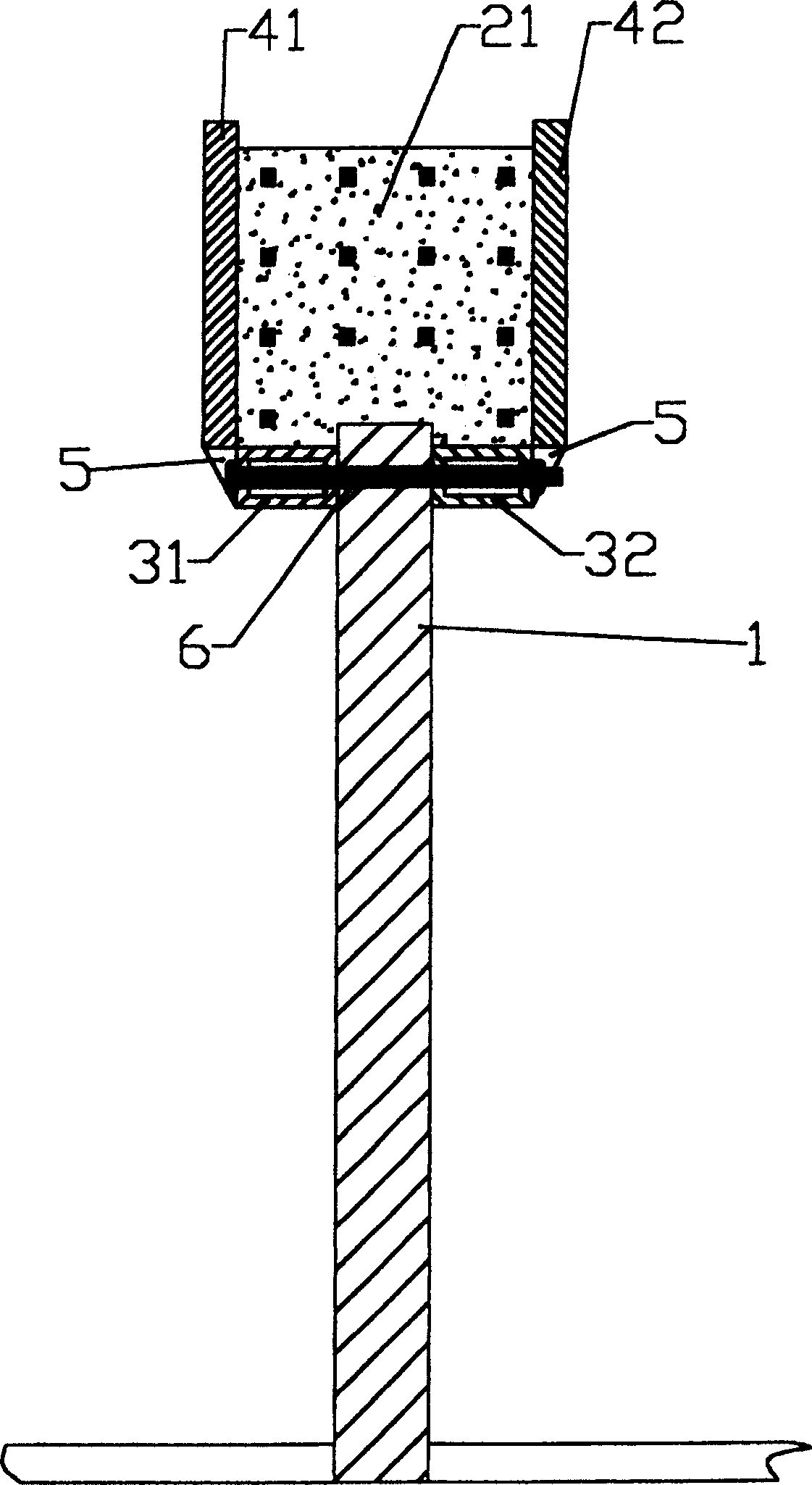

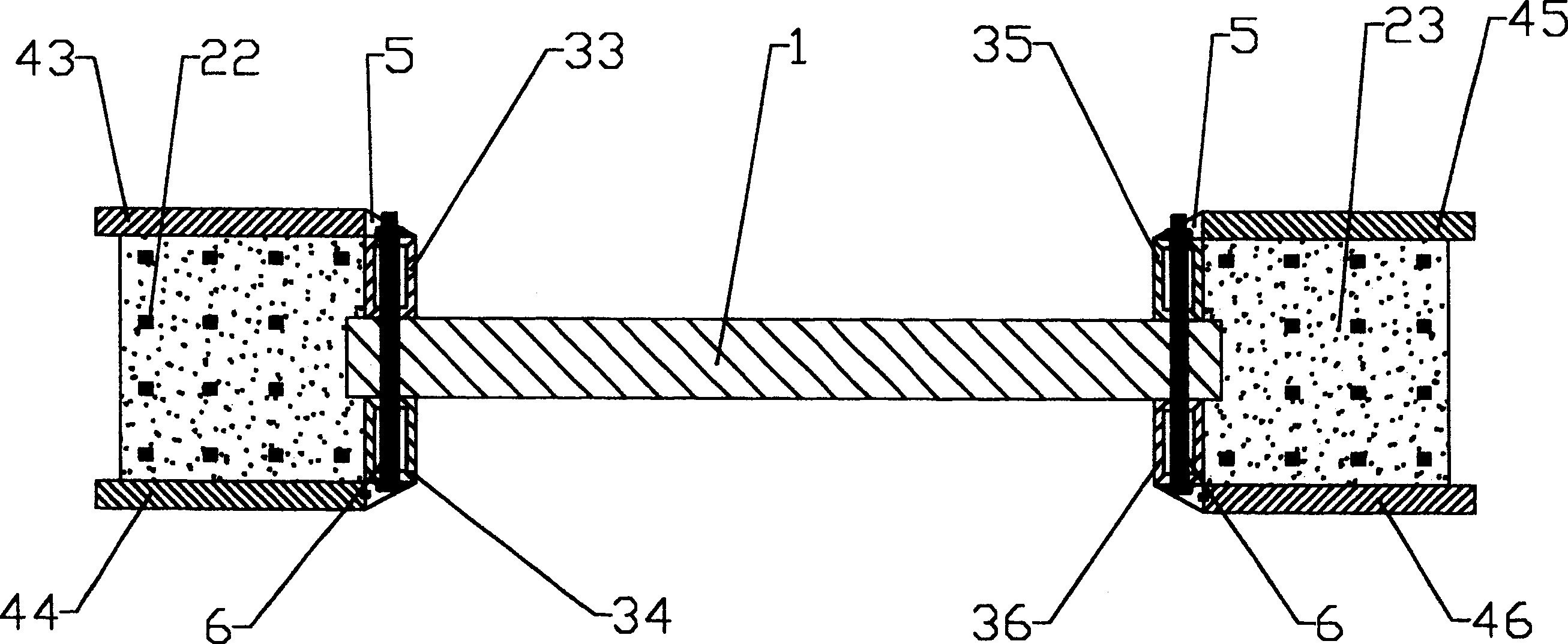

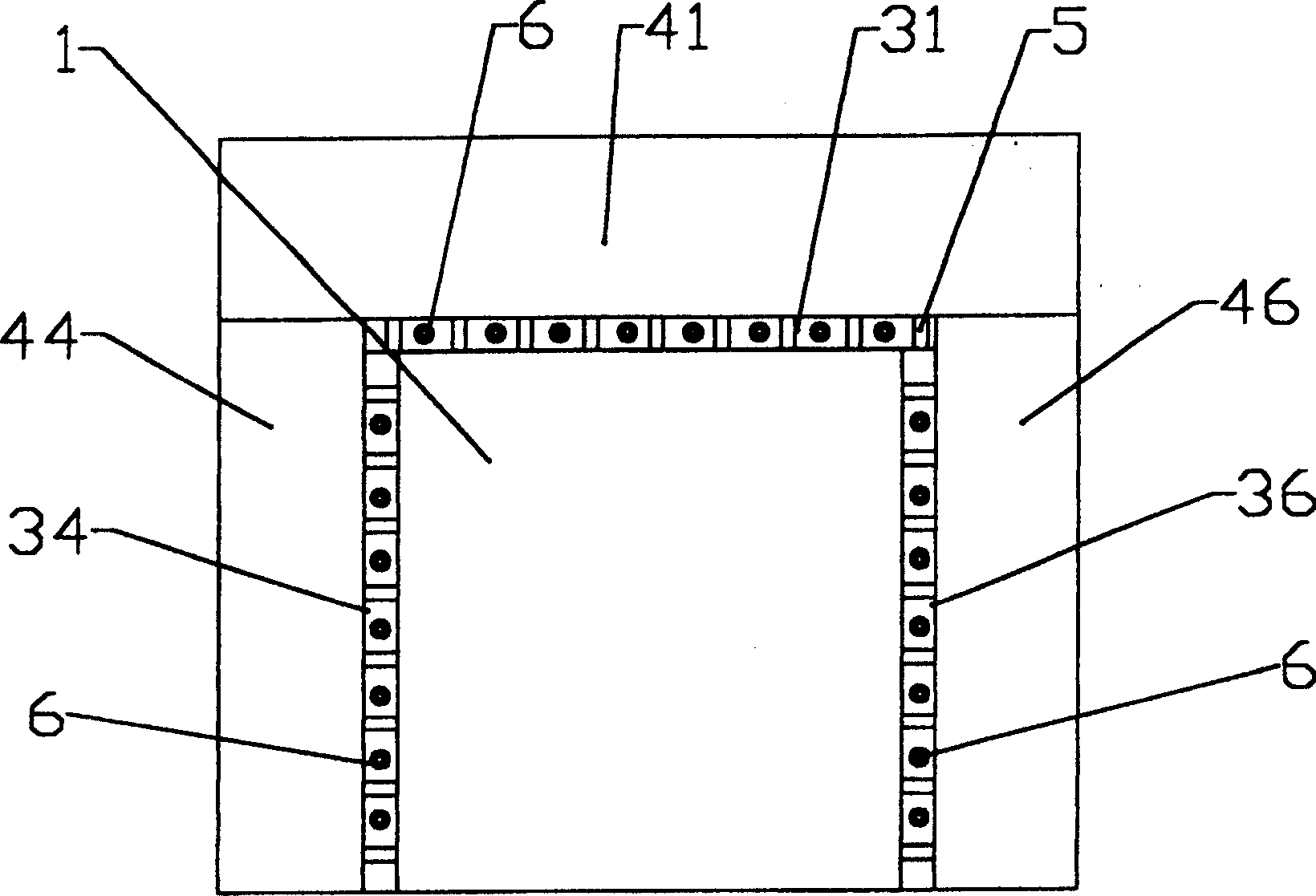

[0022] Examples, as attached figure 1 , 5 , 6, the special formwork 31, 32 is fixed on the lightweight wallboard 1 with the fixing device 6, and before the load-bearing beam 21 that needs to be poured is poured, the lightweight wallboard 1 is vertically placed on the light wall to be installed. The position of the plate 1, the special formwork 31, 32 is relatively fixed on both sides of the light wallboard 1 with the fixing device bolt 6, and the beam formwork 41, 42 is connected with the wing plate 7 on the metal square tube 9, A plurality of triangular stiffeners 8 provided between the wing plate 7 and the metal square tube 9 can support and reinforce the wing plate 7. When pouring, the wings 8 of the special formwork 31, 32 can be supported under The special formwork 31, 32 is matched with the common beam formwork 41, 42 to form the pouring area of the load-bearing beam 21, and the edge part of the light-weight wallboard corresponding to the load-bearing beam 21 is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com