In-mould formed labelled container by utilizing coild label with veiwing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

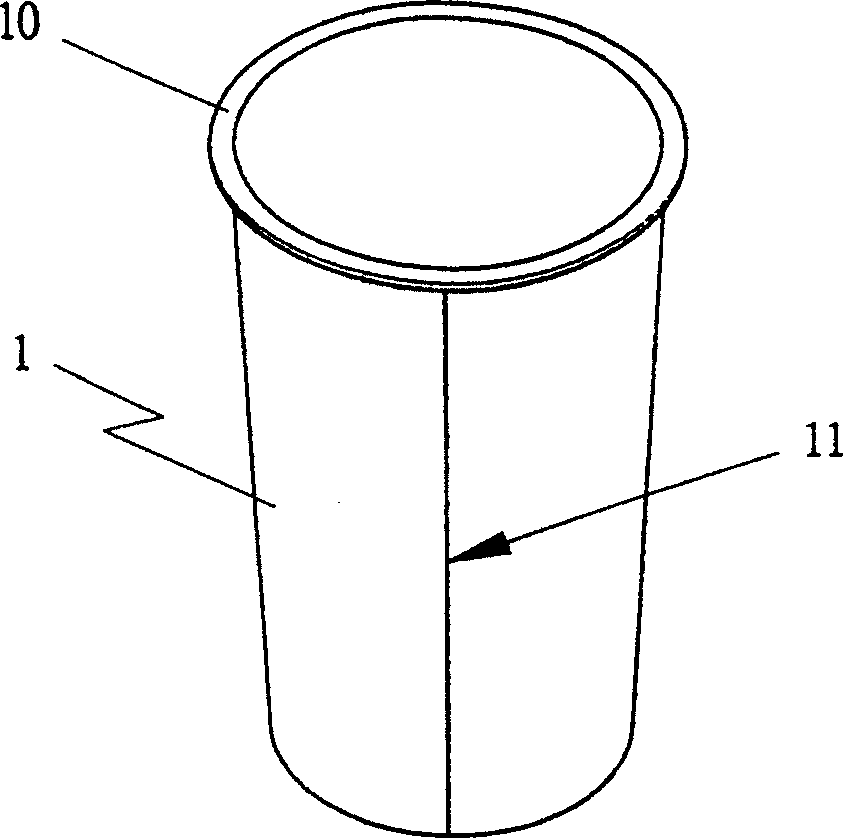

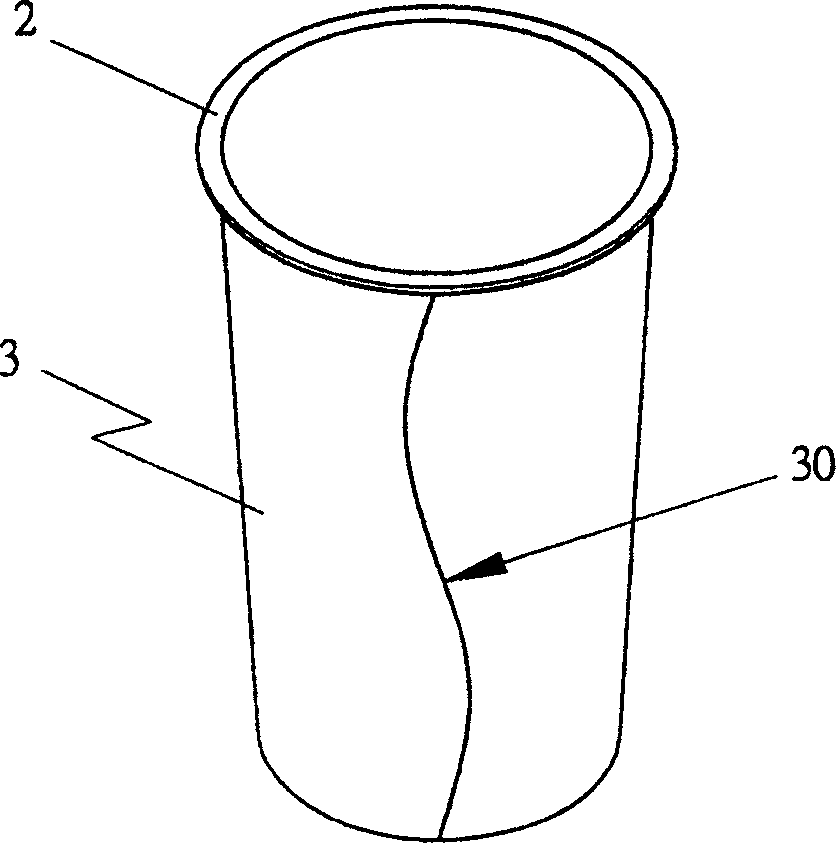

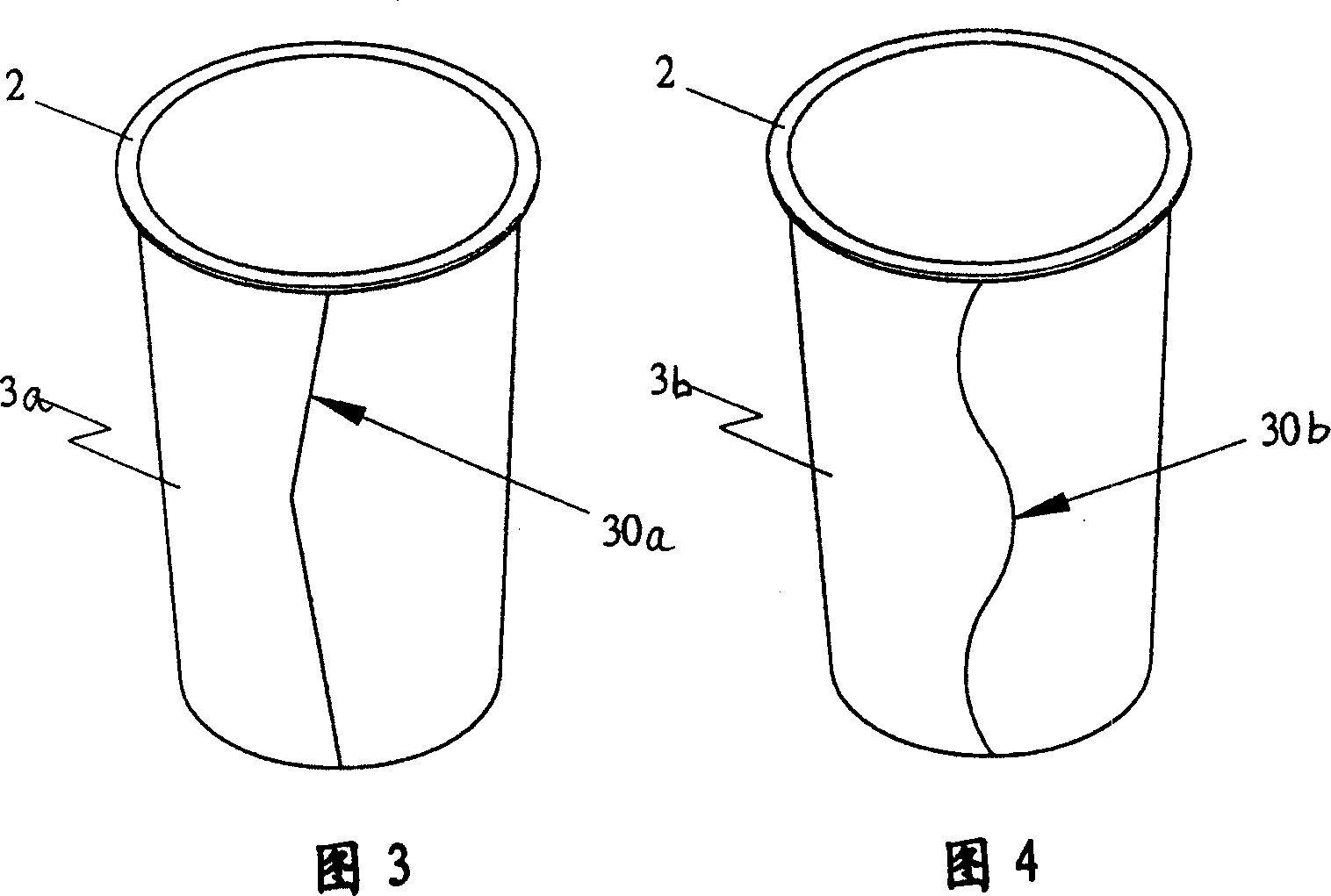

[0034] Such as figure 2 , Fig. 3, Fig. 4, Fig. 5, shown in Fig. 6, the present invention is made with the molding method of label in-mold labeling, and it at least comprises plastic container body 2 and the volume label 3 ( 3a, 3b, 3c, 3d).

[0035] The plastic container body 2 can be a plastic container of various shapes such as cups, bottles, jars, and plates, that is, it can be a plastic container of any shape. The plastic container body 2 is made of plastic material by methods such as injection molding, extrusion molding or vacuum forming, that is, any plastic container molding method is applicable.

[0036] Labels 3 (3a, 3b, 3c, 3d) are pre-printed with required characters or patterns, and the labels 3 combined with the outer surface of the plastic container body 2 are provided with joints 30 (30a , 30b, 30c, 30d).

[0037] Such as figure 2 As shown, the label 3 is provided with a joint portion 30 in a ~ shape.

[0038] As shown in Figure 3, the label 3a is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com