Connecting method for piston type flexible socket pipeline

A connection method, piston-type technology, applied in the direction of adjustable connections, pipes/pipe joints/fittings, passing components, etc., to achieve the effects of improving work efficiency, reducing economic losses, and reliable installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

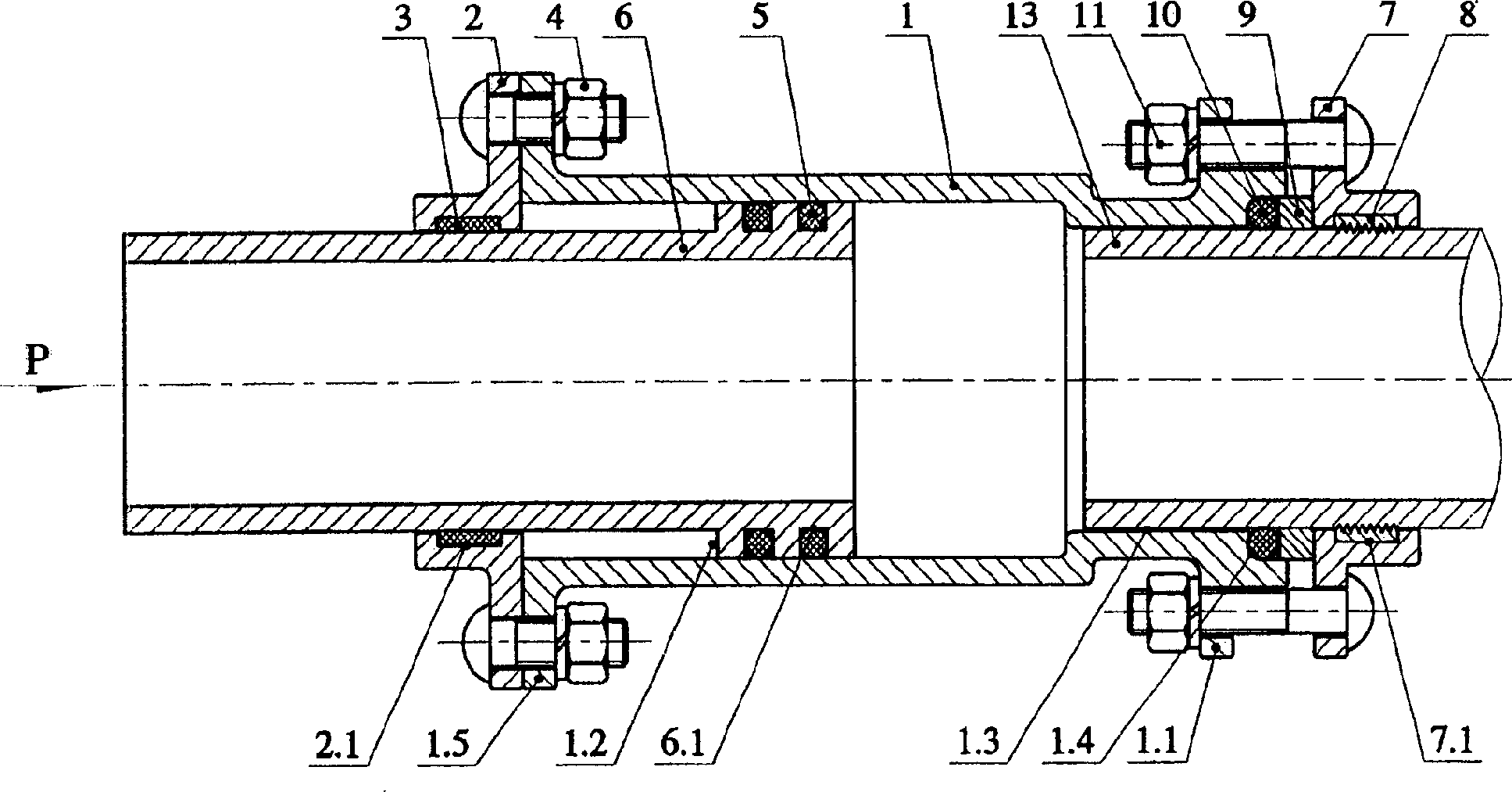

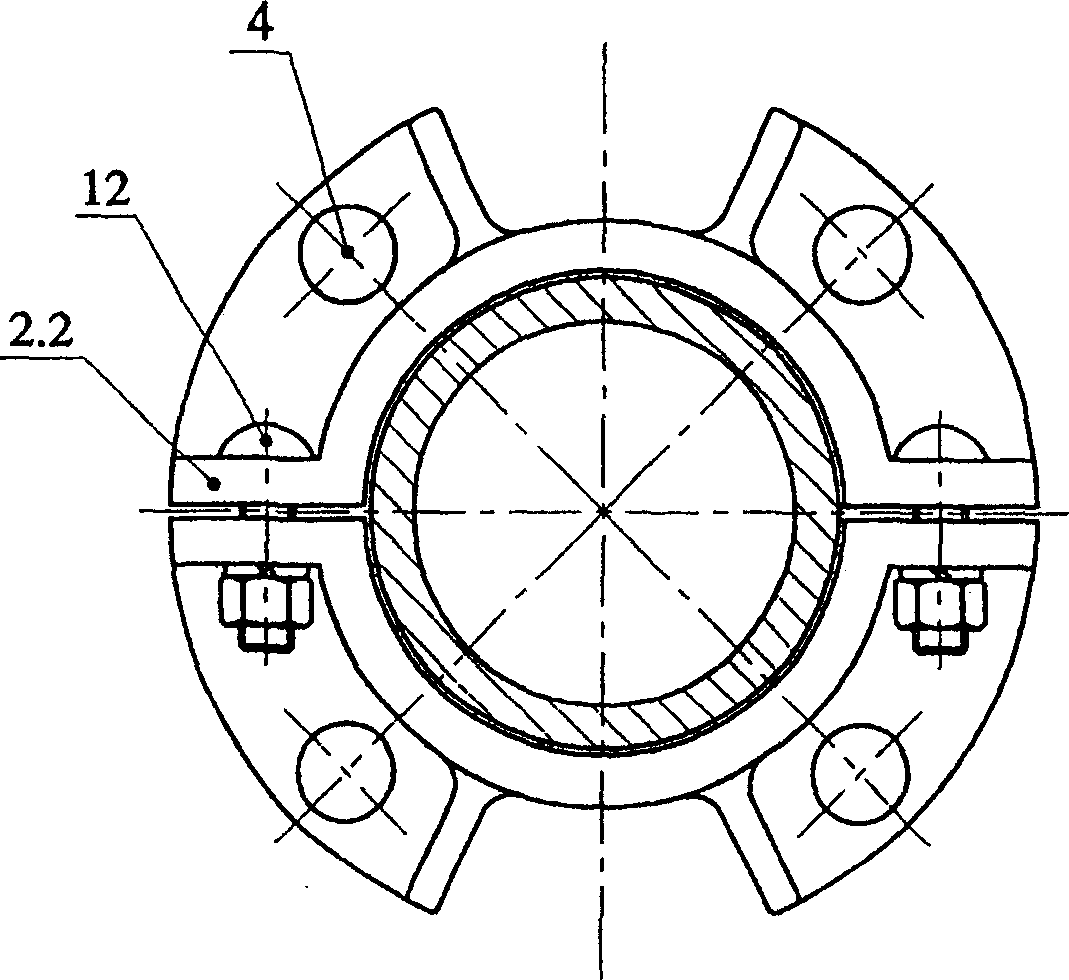

[0039] The specific implementation, structure, features and effects of the piston-type sliding flexible socket pipe connection method according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0040] see figure 1 with figure 2As shown, the piston-type sliding flexible socket pipe connection method of the present invention mainly includes a pipe fitting main body 1, a sealing flange piece 2, a sealing oil top 3, a sealing bolt 4, a piston sealing ring 5, a piston-type sliding pipe 6, and a buckle hoop Flange piece 7, engaging tooth block 8, washer 9, pipe sealing ring 10, flange bolt 11, clamp bolt 12 and pipe 13. The two piston sealing rings 5 are embedded in the two rectangular sealing grooves 6.1 of the piston end of the piston sliding pipe 6, and the piston end of the piston sliding pipe 6 is inserted into the sliding pipe sleeve chamber 1.2 of the pipe fitting main body 1. At the 1 / 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com