Anchor rod assembly and anchorage device with same

A technology of bolts and components, which is applied in the direction of installation of bolts, sheet pile walls, mining equipment, etc., can solve problems such as high repair rate, damage of support structure, failure of bolt support, etc., and achieve maintenance safety and stability, control Deformation of surrounding rock and effect of enlarging the effective section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

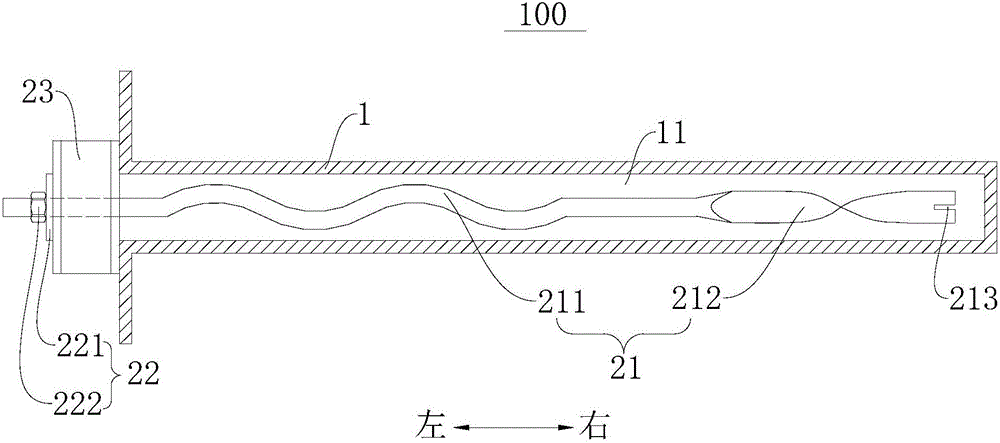

[0053] refer to figure 1 The anchoring device 100 includes a base body 1 and a bolt assembly 2, wherein the base body 1 may be surrounding rock, and an installation hole 11 is formed on the base body 1, and the installation hole 11 is filled with an anchoring agent.

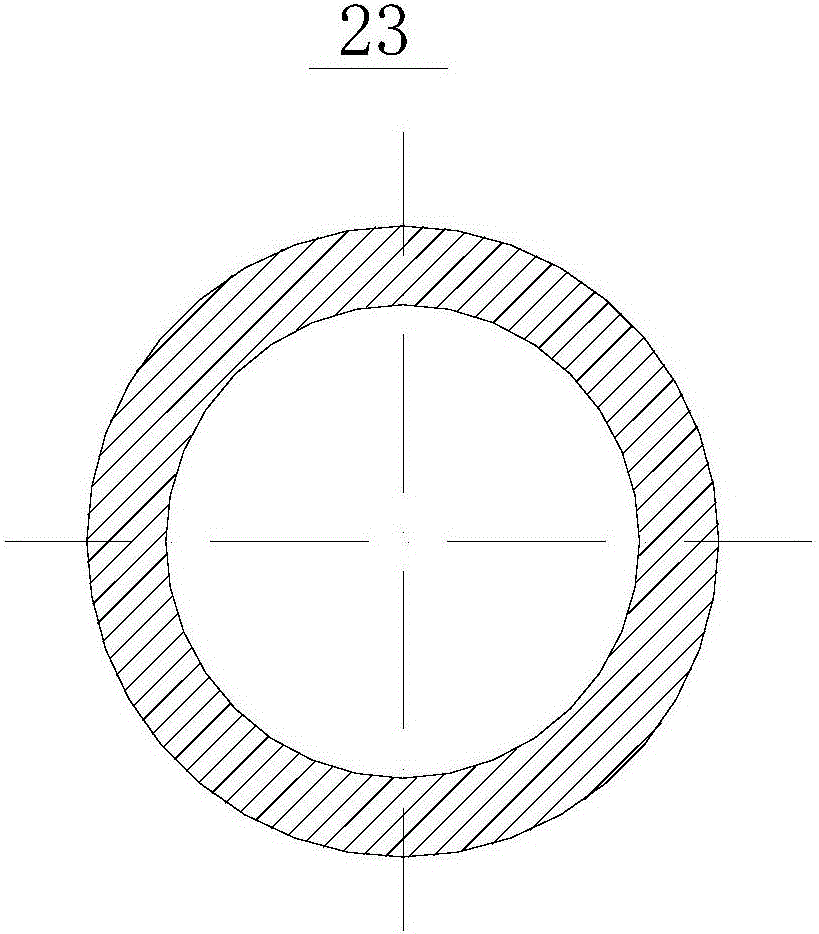

[0054] The anchor rod assembly 2 includes an anchor rod 21 , a pressing member 23 and a limiting member 22 . Wherein, the anchor rod 21 extends along the left-right direction, and the anchor rod 21 includes a curved section 211 inserted into the installation hole 11 and a stirring section 212, the curved section 211 is corrugated extending along the left-right direction; the stirring section 212 is connected to the right end of the curved section 211 , and the stirring section 212 is in a flat shape extending from left to right. In the direction from left to right, the stirring section 212 is in a twist shape gradually twisting around the axis of the anchor rod 21. Further, the end face of the right end of the st...

Embodiment 2

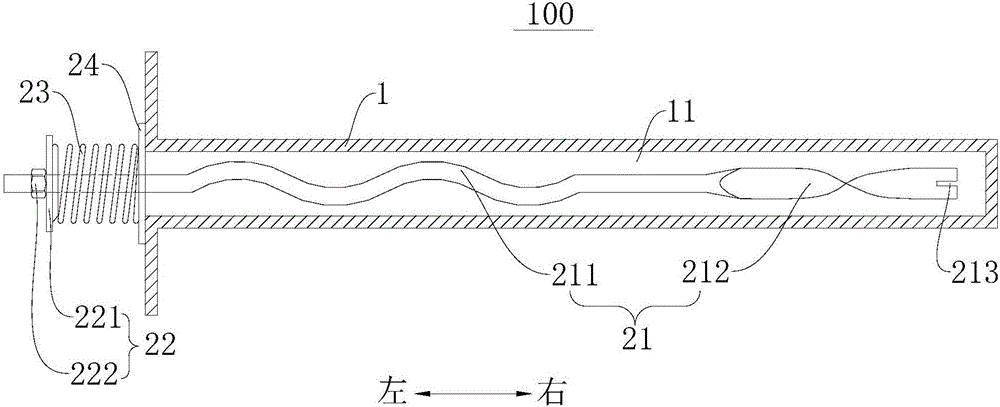

[0059] Such as figure 2 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the only difference is that: the anchor rod assembly 2 in Embodiment 1 only includes the anchor rod 21, pressure relief Part 23, position-limiting part 22, and allow pressure part 23 to be a steel pipe. However, the bolt assembly 2 described in the second embodiment includes a bolt 21, a pressing member 23, a limiting member 22 and a second backing plate 24, and the second backing plate 24 is placed between the pressing member 23 and the surrounding rock. And let the pressing member 23 be a spring, wherein the spring can be a cylindrical coil spring, a disc spring, a composite spring, or a bellows.

[0060] According to the anchoring device 100 of the embodiment of the present invention, the spring of the pressing member 23 can apply a certain prestress to the anchor rod 21 to realize active support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com