Finger protection type heat insulation seal door panel construction

A technology for sealing door panels and finger protection, applied in sealing devices, door/window accessories, building structures, etc., can solve the problems of unsatisfactory heat insulation effect, and the thermal insulation effect of the door splicing is not as good as the door panel itself, etc., to achieve technological progress Highlight and reduce the effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

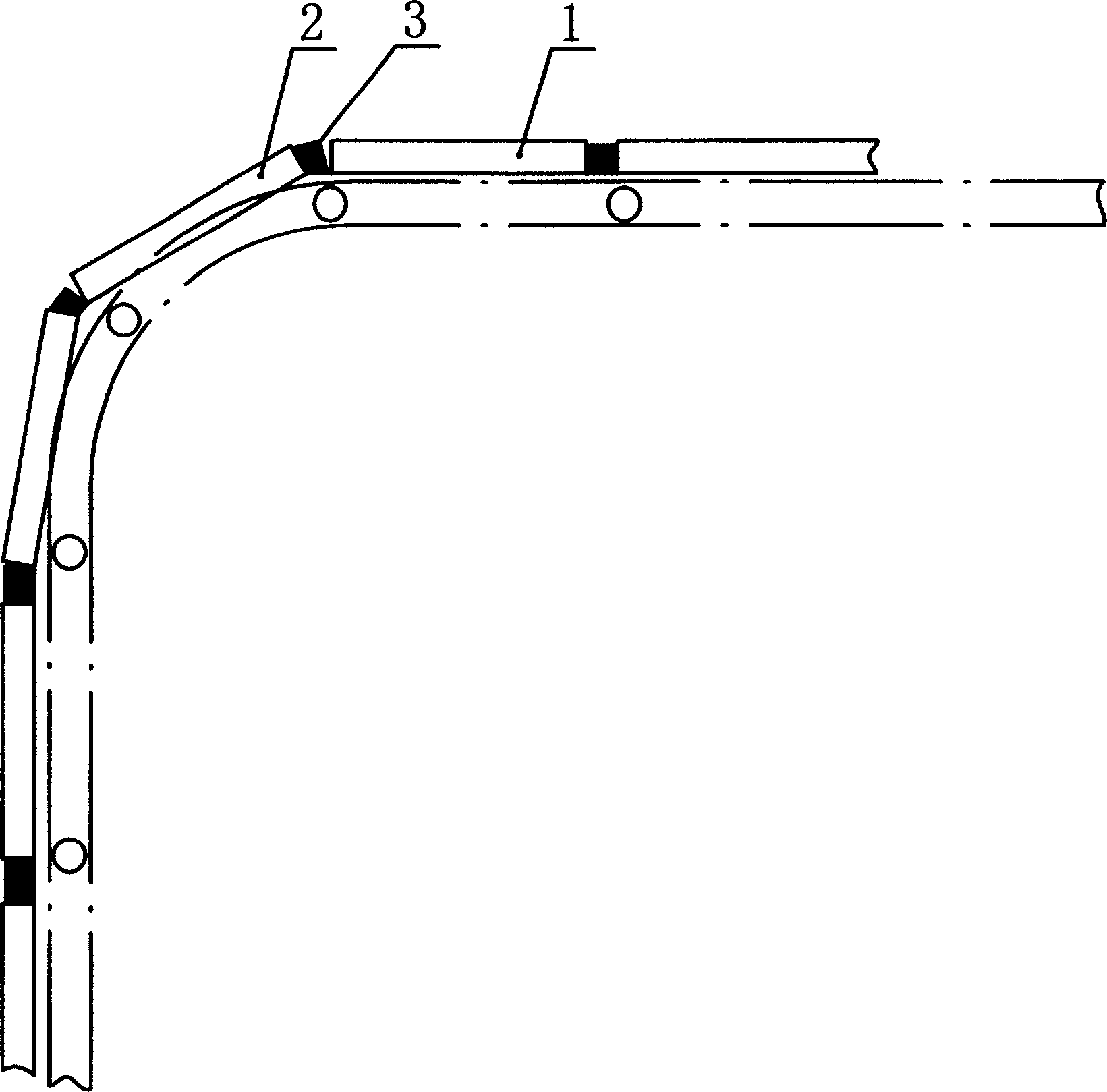

[0050] Embodiment one: see figure 1 As shown in the figure, a finger-protected heat-insulating and sealed door panel structure uses door pieces of the same shape and structure as units, and each unit is parallel and juxtaposed. The inner side constitutes a flexible door panel structure that can be folded along the hinge axis.

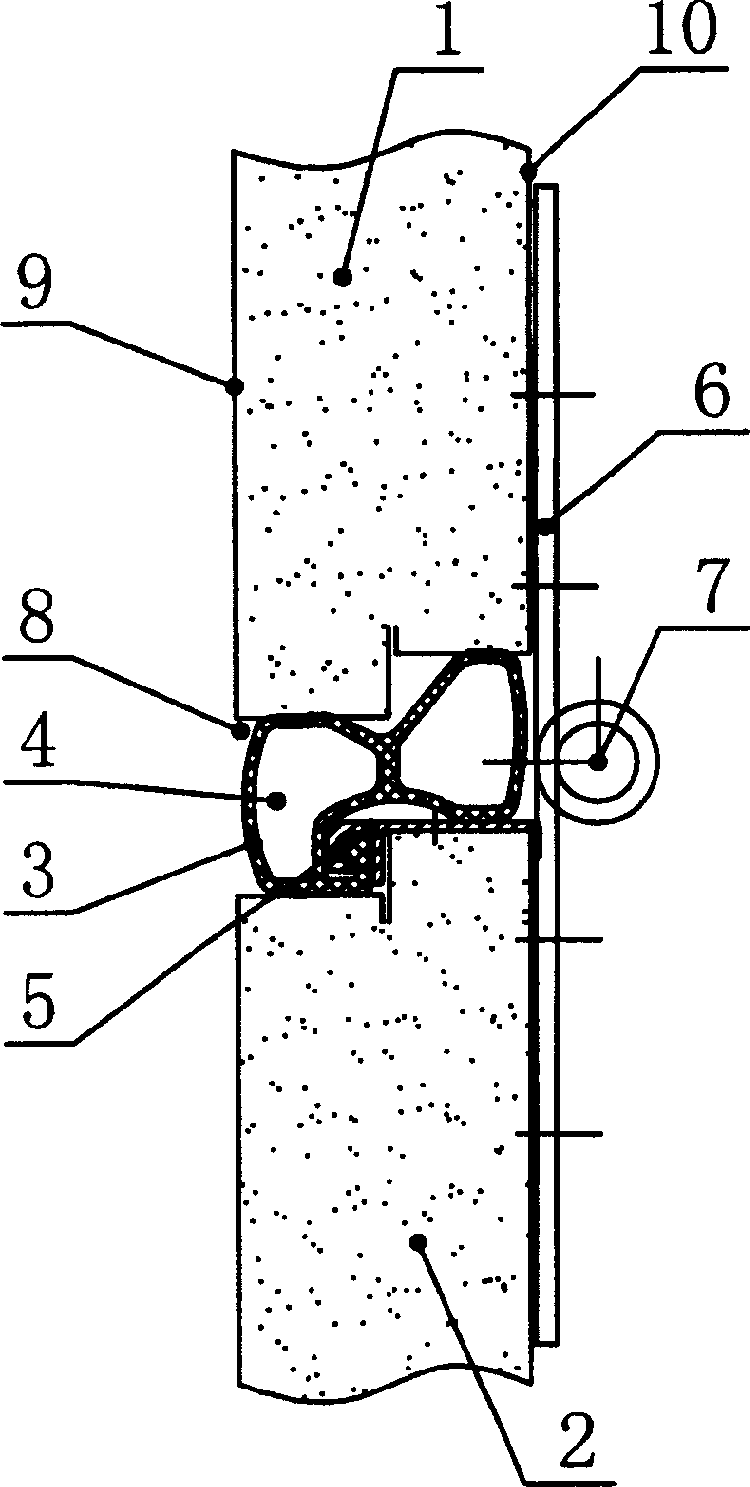

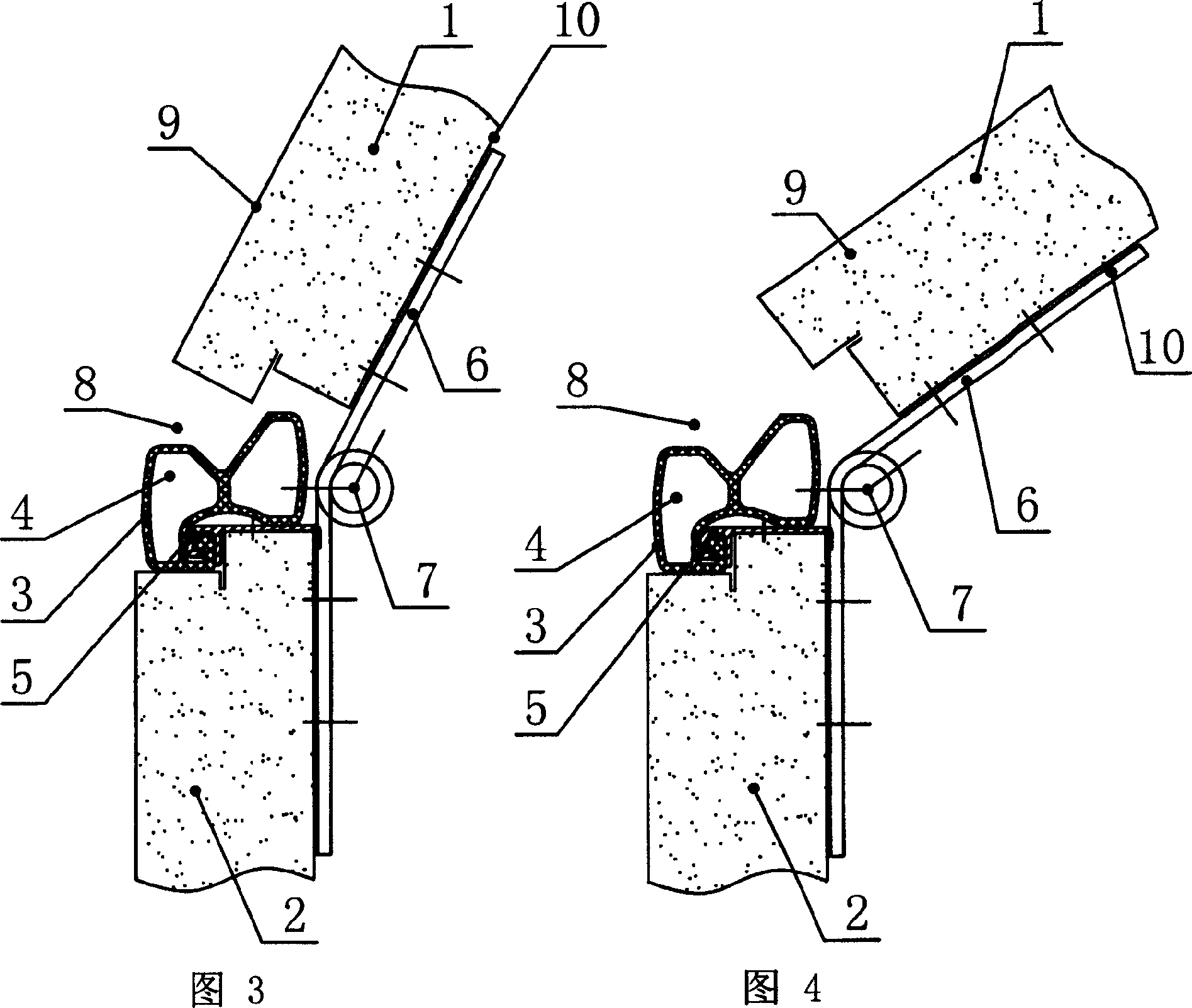

[0051] see figure 2 As shown, the upper door 1 and the lower door 2 are hingedly connected by the hinge 6 of the inner side 10, and the gap 8 spliced between the upper door 1 and the lower door 2 is divided into an inner half and an outer half in the thickness direction of the door. The two gaps are dislocated up and down to form steps, wherein the narrowest part of the gap is larger than the width of an adult's finger, and an elastic sealing strip 3 is arranged in the gap 8, and the elastic sealing strip 3 is composed of two juxtaposed, dislocated, connected bodies inside and outside. One is located in the inner half of the gap, and the outer one ...

Embodiment 2

[0057] Embodiment two: see Figure 5 As shown in FIG. 7 , the difference between this example and the first embodiment is that the hinge shaft 7 is located in the gap 8 , while the hinge shaft 7 of the first embodiment is located outside the gap 8 . Other structures are the same as those in Embodiment 1, and will not be repeated here.

[0058] In addition, in order to make full use of the role of the hollow elastic sealing strip 3 in the entire product, the elastic sealing strip 3 can be made of transparent or translucent materials, and the hollow cavity is separated from each other along the length by light emitting diodes or light bulbs. The light bulb is connected to the power supply through wires. The luminescence of the diode can be in the form of flickering, and can also be in a variety of transformation forms, which are all controlled by the circuit, so that the control circuit and the connection mode of the light-emitting diode adopt the currently known prior art. An...

Embodiment 3

[0059] Embodiment three: see Figure 8 As shown, this example has the same structural features as Embodiment 1, except that the shape of the elastic sealing strip 3 and the shape of the hollow cavity 4 are different. For details, see Figure 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com