Multidirection input device

A multi-directional input device and component technology, which is applied to mechanical control devices, input/output processes of data processing, control mechanisms equipped with multiple controlled components, etc. It is not a certain problem, such as discrete pressing force, to achieve smooth tilt and up and down movement, good operation feeling, and small height size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

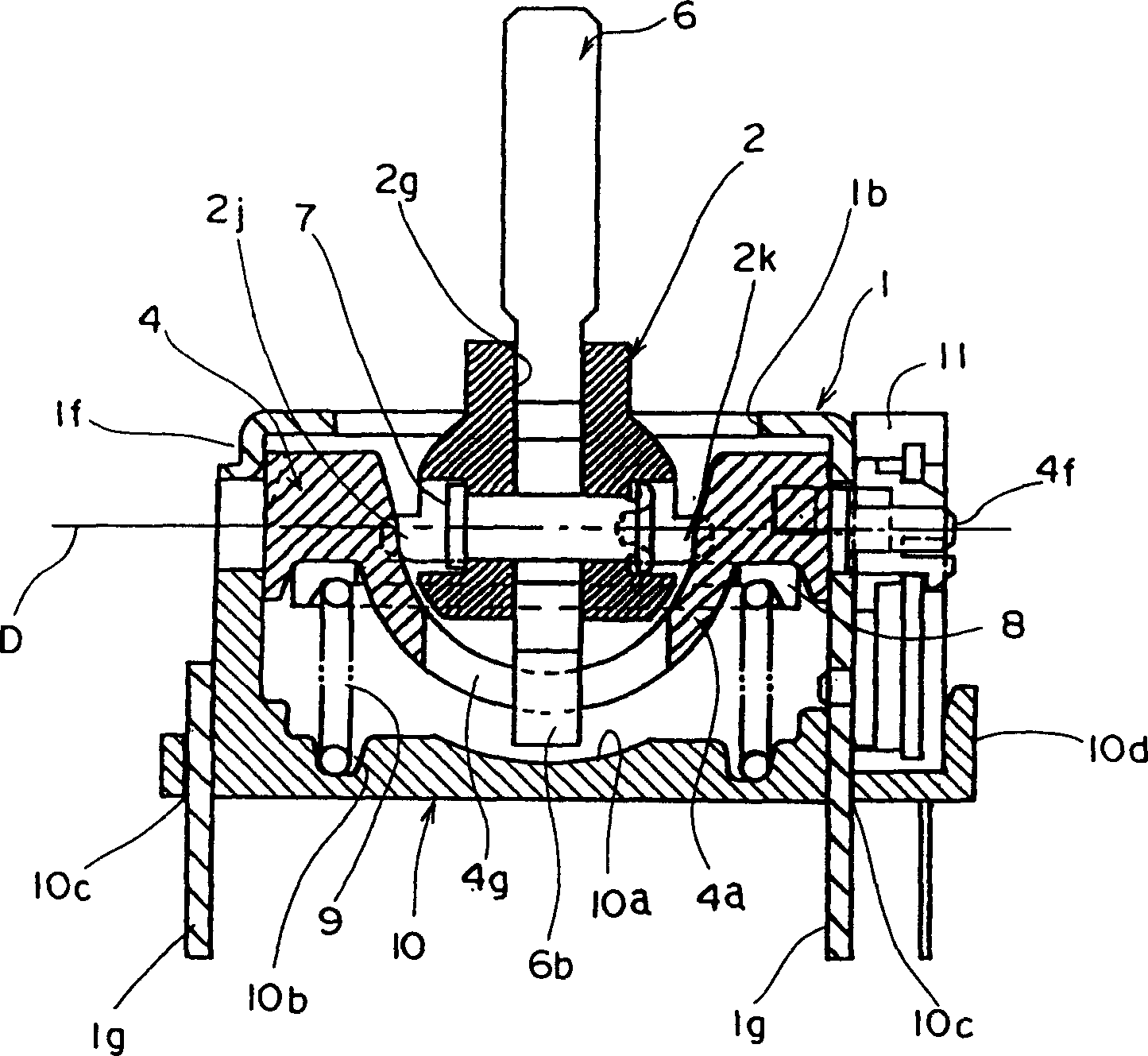

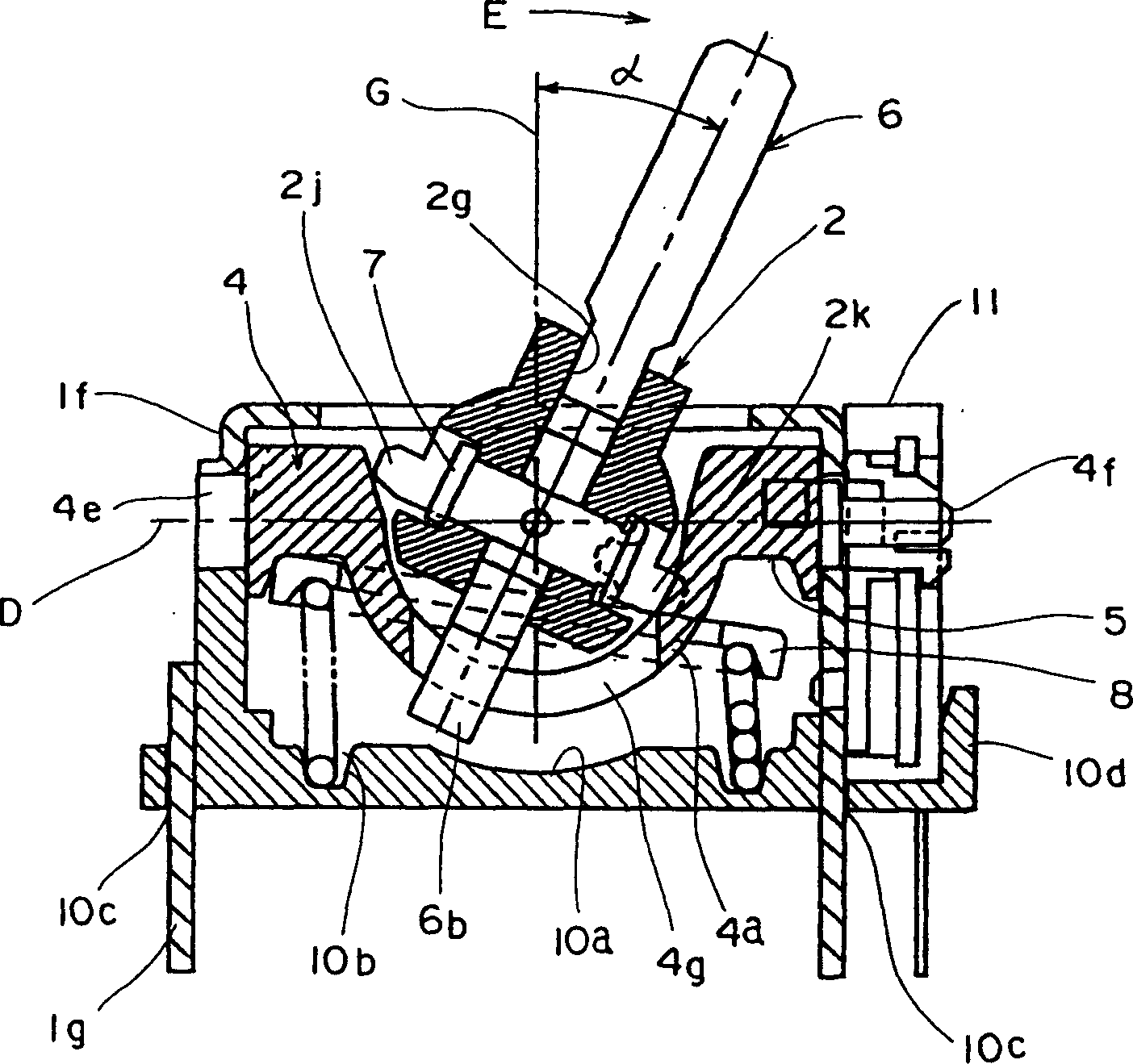

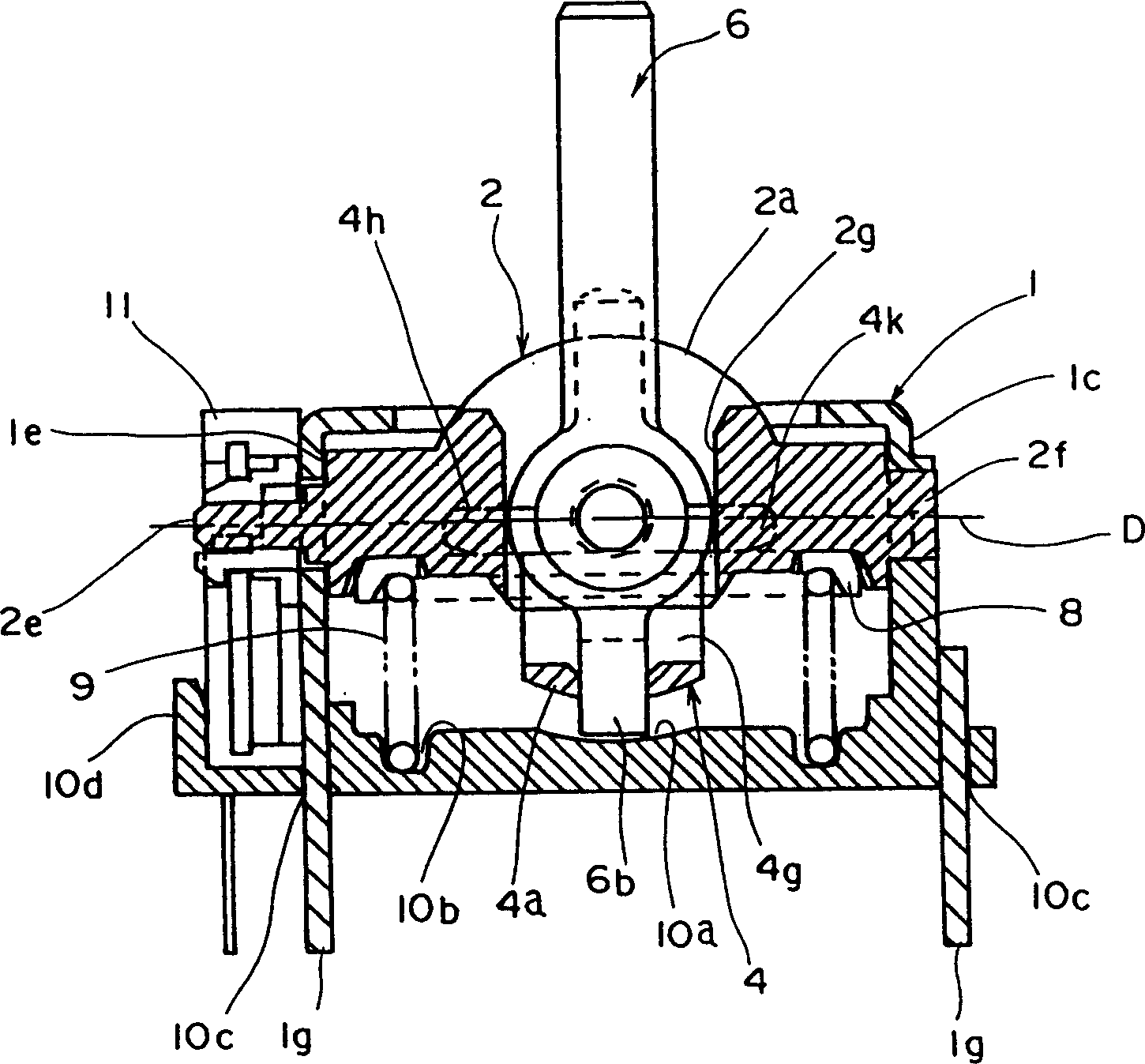

[0077] The multidirectional input device of the present invention such as Figure 5 As shown, the box-shaped housing 1 made of iron plates is bent and formed by stamping and other methods, and the upper part is covered by an upper plate 1a, which is provided with a circular operating hole 1b, and the upper plate 1a The four sides of the shell are provided with side plates 1c, 1d, 1e, and 1f bent downward, and the inside of the shell 1 is a cavity.

[0078] Inside the cavity of the casing 1, the first and second interlocking components 2, 4 are arranged, perpendicularly intersect each other, and combined into a cross shape.

[0079] Below, refer to Figure 7 ~ Figure 10 The above-mentioned 1st interlocking part 2 is described, and the 1st interlocking part 2 is made of synthetic resin, such as Figure 8 As shown, there is a semicircular base 2a at its center, and one arm 2b protruding to the right as shown in the figure and the other arm 2c protruding to the left as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com