Ink jet printer head and ink jet printer having said ink jet printer head

A technology of inkjet head and nozzle, applied in the direction of printing, inking device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

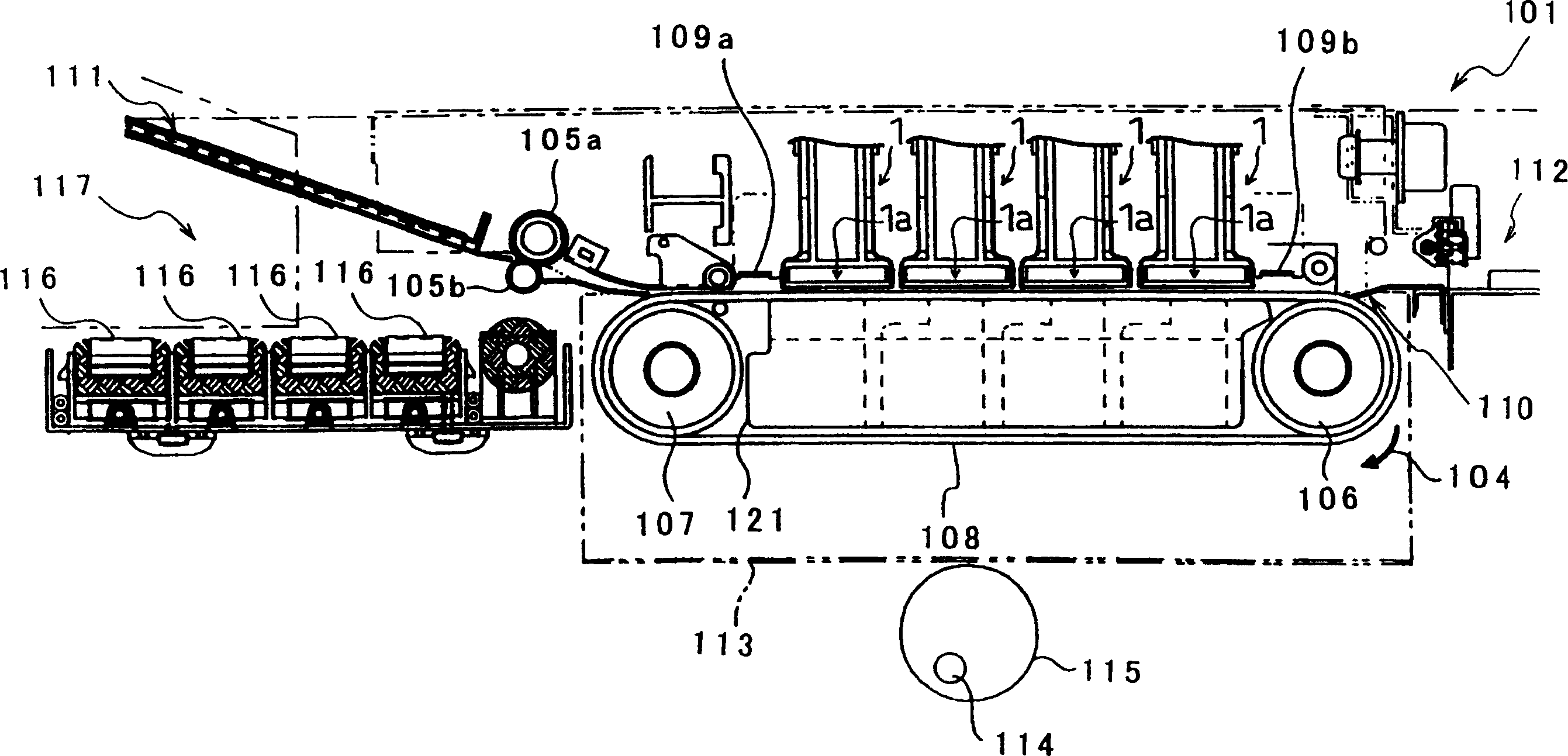

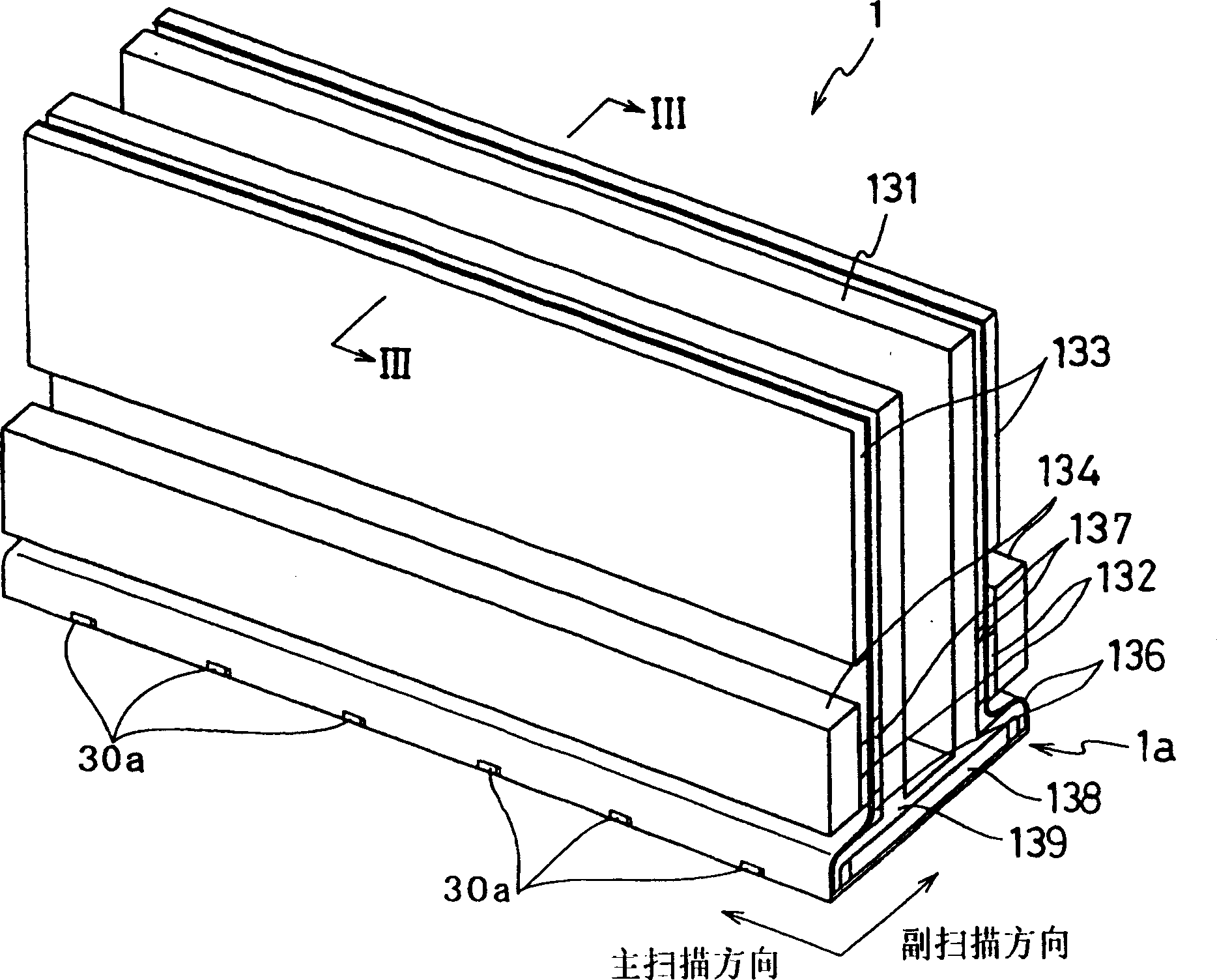

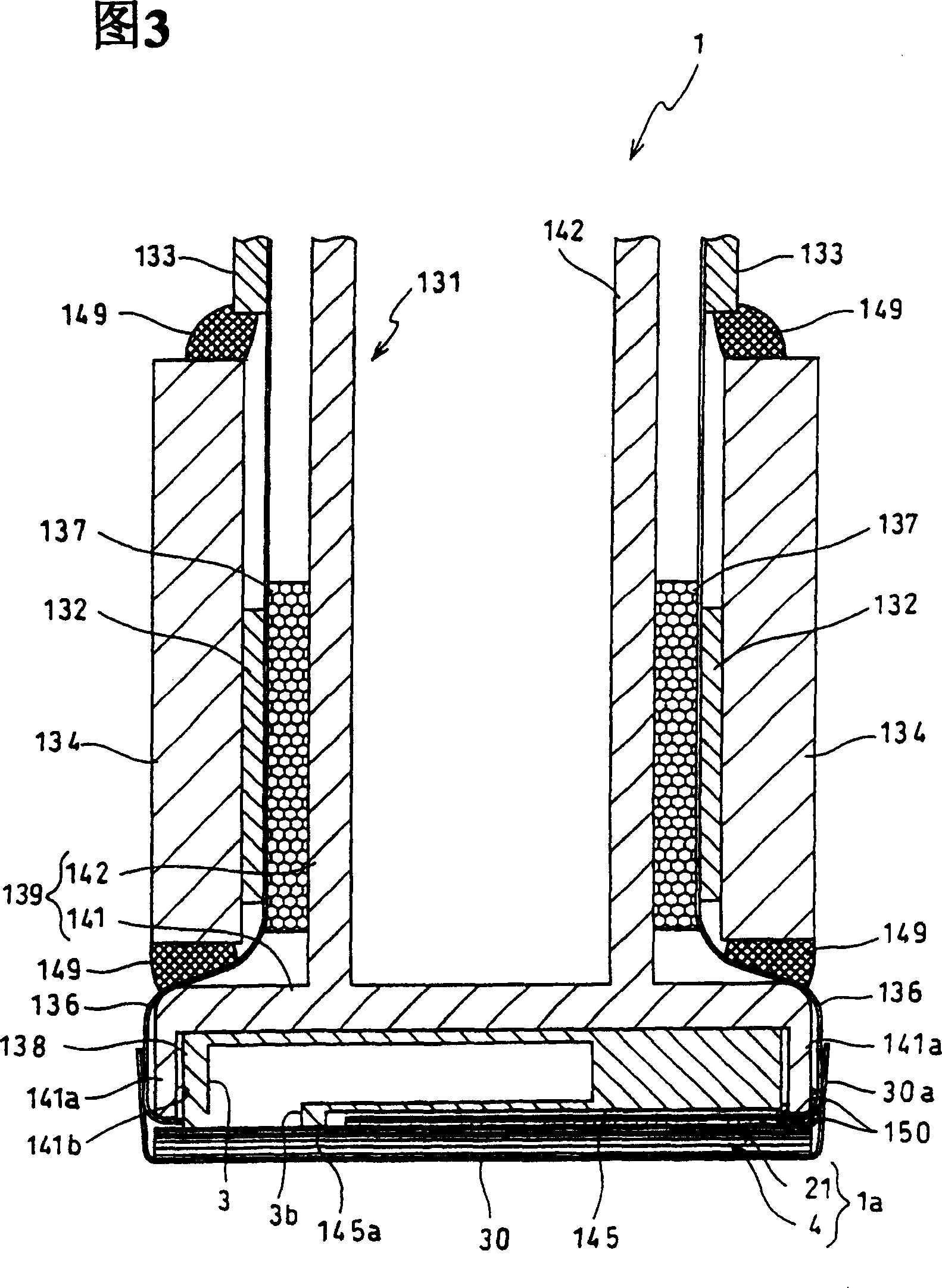

[0025] figure 1 It is a schematic diagram of an inkjet printer including the inkjet head according to the first embodiment of the present invention. figure 1 The illustrated inkjet printer, that is, an inkjet recording device 101 , is a color inkjet printer having four inkjet heads 1 . In this printer 101 , a paper feed mechanism 111 is formed on the left in the figure, and a paper discharge mechanism 112 is formed on the right in the figure.

[0026] Inside the printer 101 , a paper transport path that flows from the paper feed mechanism 111 to the paper discharge mechanism 112 is formed. On the immediately downstream side of the paper feeding mechanism 111, a pair of paper feeding rollers 105a, 105b that sandwich and convey paper as an image recording medium are arranged. The paper is conveyed from left to right in the figure by a pair of paper feed rollers 105a, 105b. In the middle of the paper conveying path, two pulleys 106, 107 are disposed, and an endless conveying b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com