High-efficiency microorganism hydrogen preparation and hydrogen energy-electric energy conversion integrating apparatus

A high-efficiency microbial and biological hydrogen production technology, which is applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical equipment and methods, etc., can solve the problem of unsatisfactory influence on the hydrogen release rate of bacterial strains, high cost of hydrogen production, microbial Problems such as low hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following embodiments will provide a detailed description of the present invention in conjunction with the accompanying drawings:

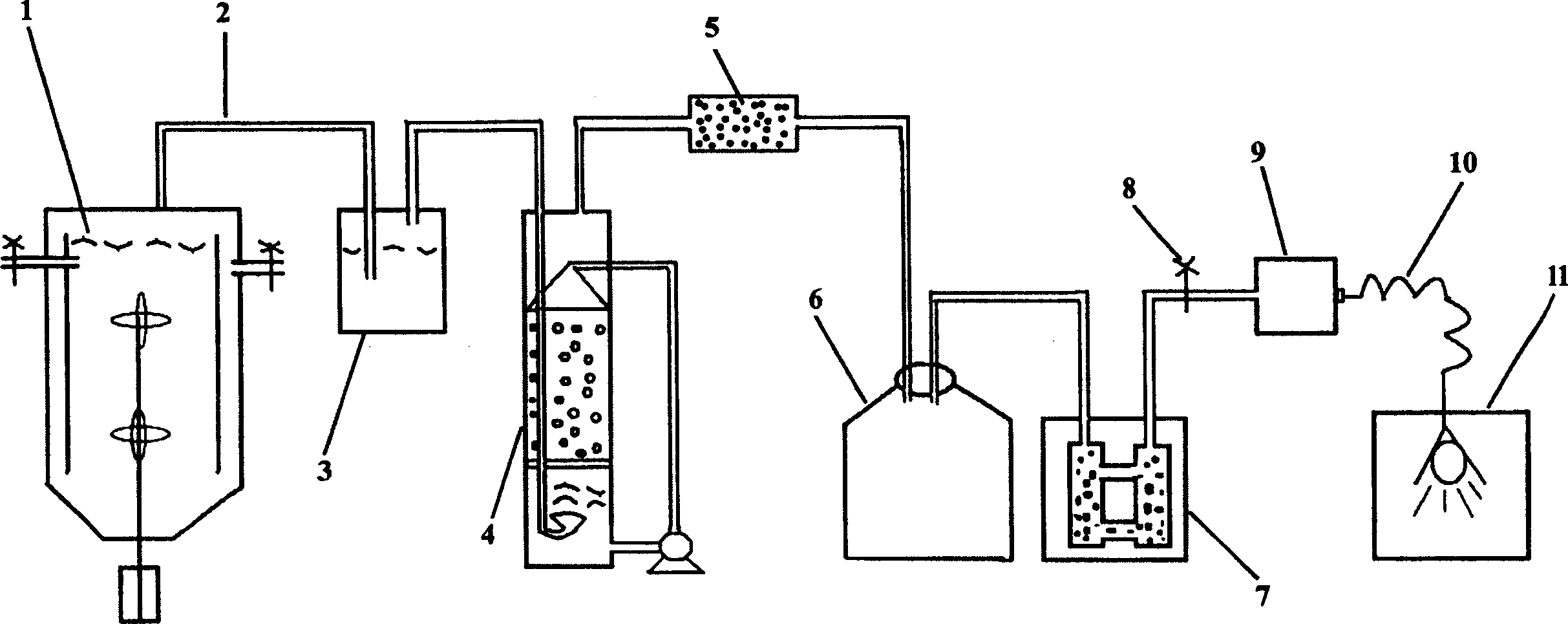

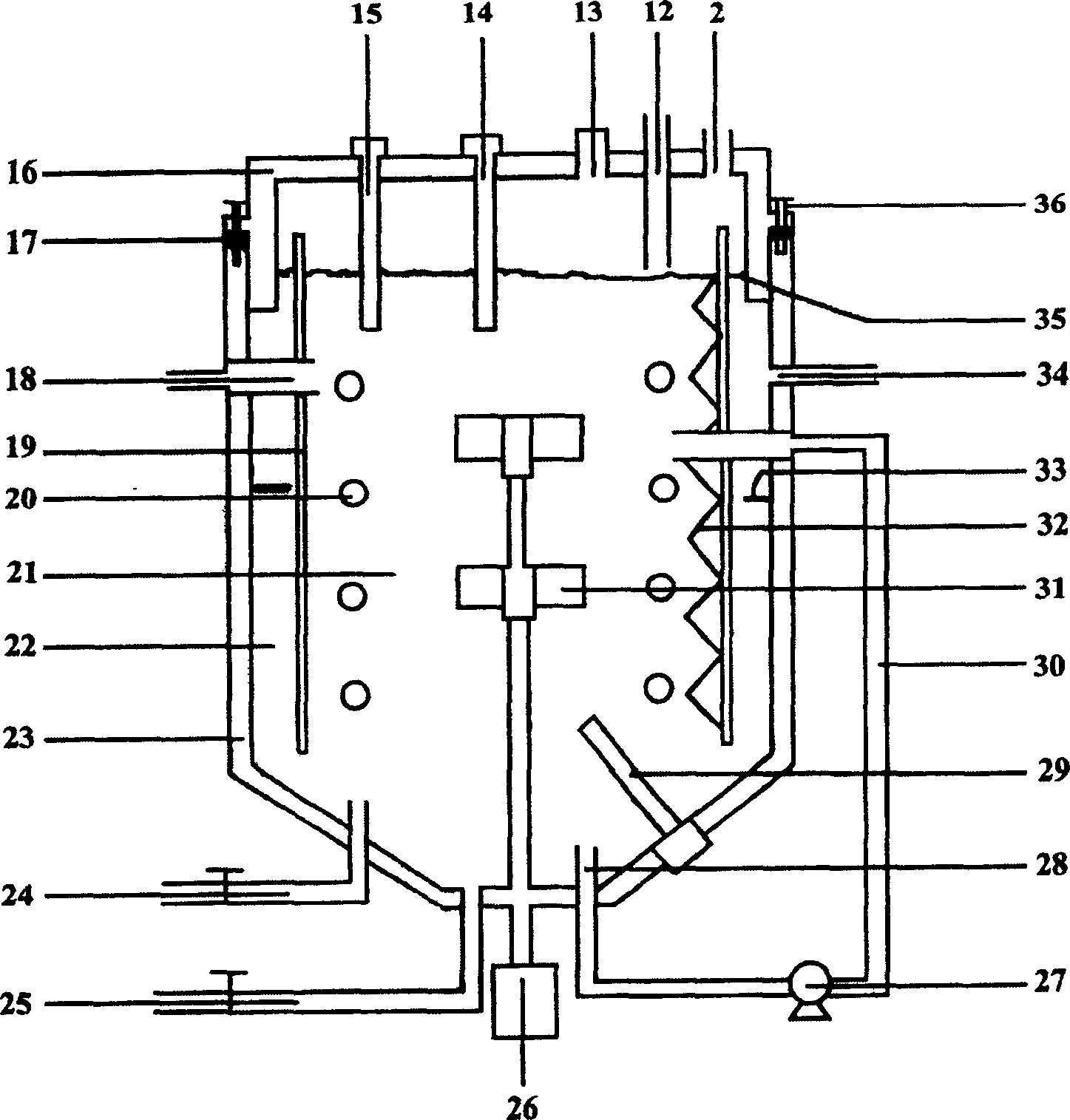

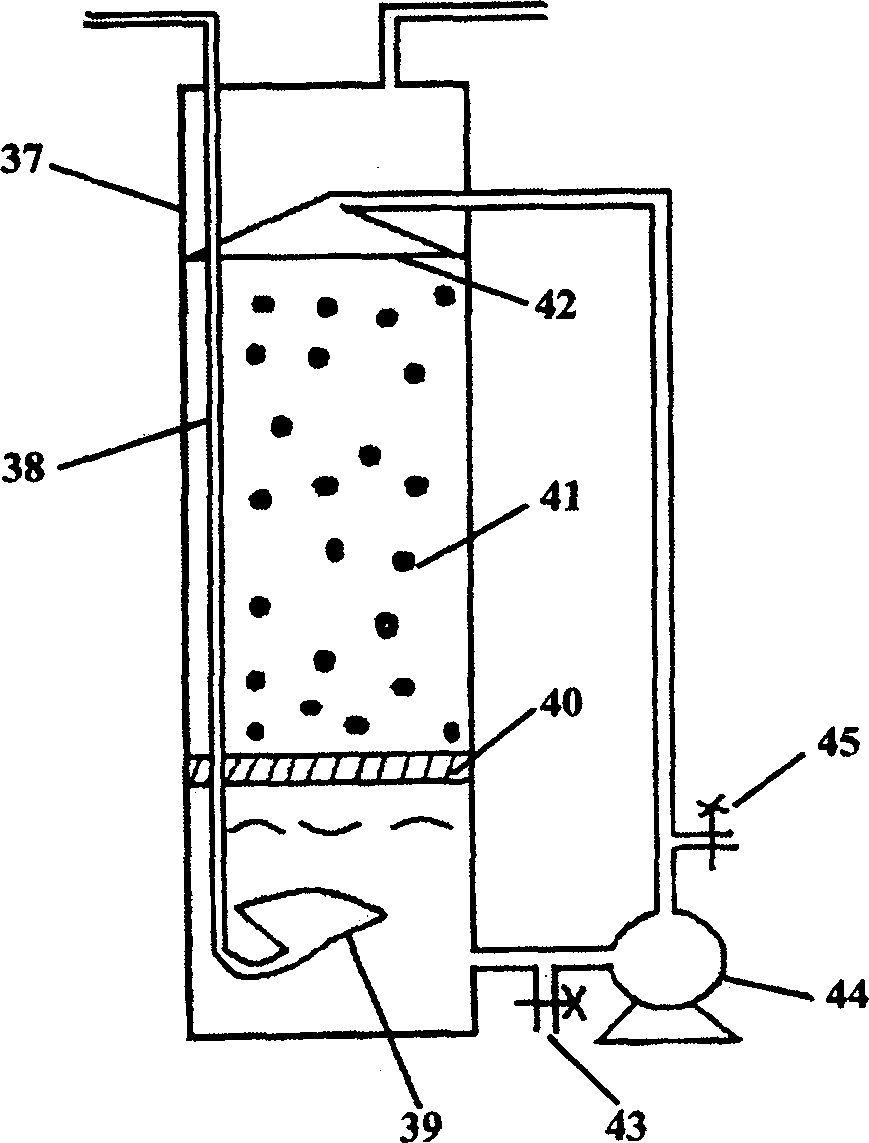

[0024] like figure 1 As shown, the present invention includes biological hydrogen production reaction device 1, water sealing device 3, alkali eluting tower 4, drying device 5, hydrogen storage cylinder 6, hydrogen storage tank 7, switch 8, proton membrane fuel cell 9 and other parts, and It is connected to electrical equipment 11 (such as lighting or electric devices) through wires 10 . figure 2 It is a schematic diagram of the structure of the biohydrogen production device. The biohydrogen production device is equipped with a fermentation tank, a stirring system, a temperature control system, and a pH control system. The fermenter comprises 3 parts such as an inverted cone shell 23, an inner cylinder 19 and a sealing cover 16. The shell 23 is made up of inner and outer layers, with a heat insulation layer in the middle. The inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com