Catalytic diesel oil combined treatment process and treatment system

A technology for catalyzing diesel oil and treatment process, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of strong heat release, short operation period of the device, and low yield, so as to reduce the amount of cold hydrogen and reduce the Operation cost and effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

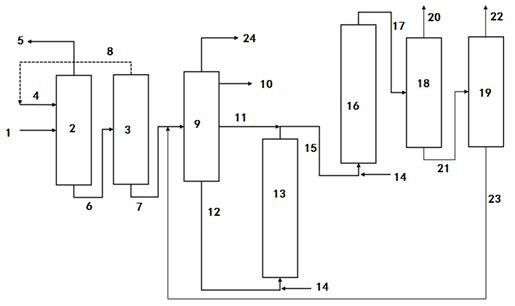

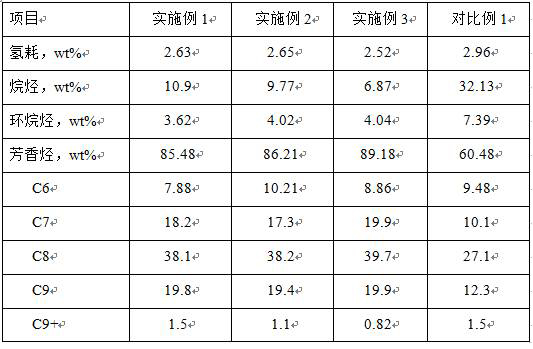

[0047] This embodiment adopts figure 1 As shown in the process flow, the catalytic diesel oil enters the pretreatment unit, wherein the pretreatment unit is an aromatic hydrocarbon extraction device, the extraction agent is sulfolane, the extraction temperature is 170 ° C, and the mass ratio of the agent to oil is 15.0; after extraction, the rich aromatic hydrocarbon components enter the fractionation unit, light The dry point temperatures of the distillate and middle distillate were 220°C and 310°C, respectively. The first and second fluidized bed reaction zones use the same hydrogenation catalyst. The hydrogenation catalyst is the one developed by the Dalian Petrochemical Research Institute of China Petroleum & Chemical Co., Ltd. FC-70 catalyst, wherein the hydrogenation catalyst used in the second fluidized bed reaction zone is the catalyst after the first fluidized bed reaction zone has been operated for 3 months; the temperature of the first fluidized bed hydrogenation re...

Embodiment 2

[0049] This embodiment adopts figure 1 As shown in the process flow, the catalytic diesel oil enters the pretreatment unit, wherein the pretreatment unit is set as an aromatic hydrocarbon extraction device, N-methylpyrrolidone is selected as the extraction agent, the extraction temperature is 150 ° C, and the mass ratio of the agent to oil is 10.0; The fractions enter the fractionation unit, and the dry point temperatures of the light and middle fractions are 180°C and 290°C, respectively. The first and second ebullated bed reaction zones use the same hydrogenation catalyst, and the hydrogenation catalyst is the one that has been crushed (broken into short strips of 0.5-1.0mm) and developed by Dalian Petrochemical Research Institute of China Petroleum & Chemical Co., Ltd. FC-70 catalyst; the temperature of the first fluidized bed hydrogenation reaction zone is 410 °C, the reaction pressure is 12.0 MPa, the hydrogen-oil ratio is 700, and the liquid hourly volume space velocity ...

Embodiment 3

[0051] Basically the same as Example 1, the difference is that the extraction agent of the pretreatment unit is [emim]N(CN)2, the extraction temperature is 40 ° C, and the mass ratio of the agent to oil is 10; and the dry point temperatures of the middle distillate are 180°C and 290°C, respectively. The first and second fluidized bed reaction zones use the same hydrogenation catalyst. The hydrogenation catalyst is the one developed by the Dalian Petrochemical Research Institute of China Petroleum & Chemical Co., Ltd. FC-70 catalyst; the temperature of the first fluidized bed hydrogenation reaction zone is 410 °C, the reaction pressure is 12.0 MPa, the hydrogen-oil ratio is 700, and the liquid hourly volume space velocity is 1.0 h -1 ; The temperature of the second fluidized bed hydrogenation reaction zone is 425 °C, the reaction pressure is 12.0 MPa, the hydrogen-oil ratio is 700, and the liquid hourly volume space velocity is 0.5 h. -1 ; The specific test results are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com