Tyre with non symmetrical reinforced sidewalls

A technology of tires and reinforcements, applied in special tires, tire sidewalls, tire parts, etc., can solve problems such as difficult control by drivers, and achieve the effect of improving vehicle driving performance and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

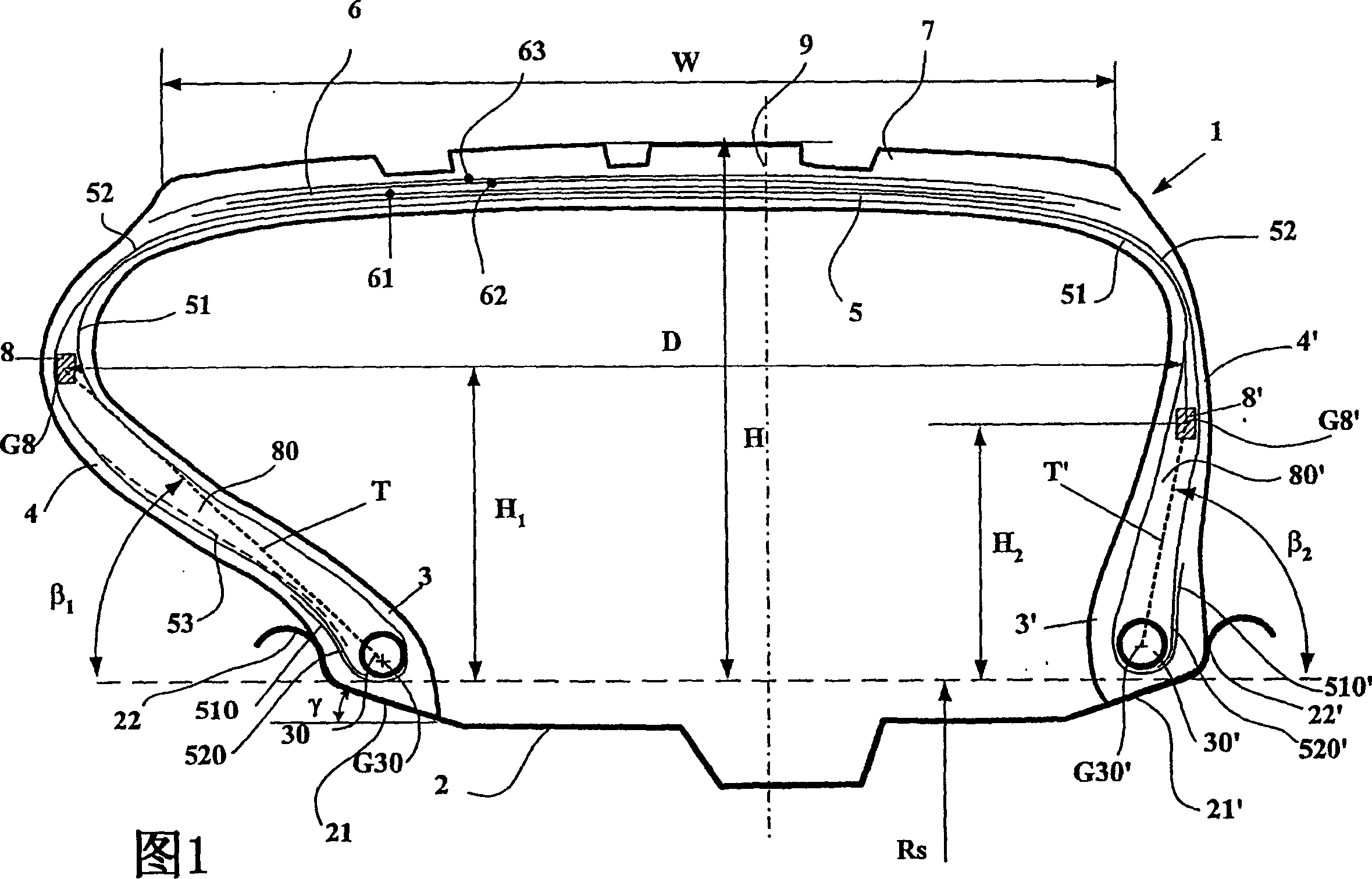

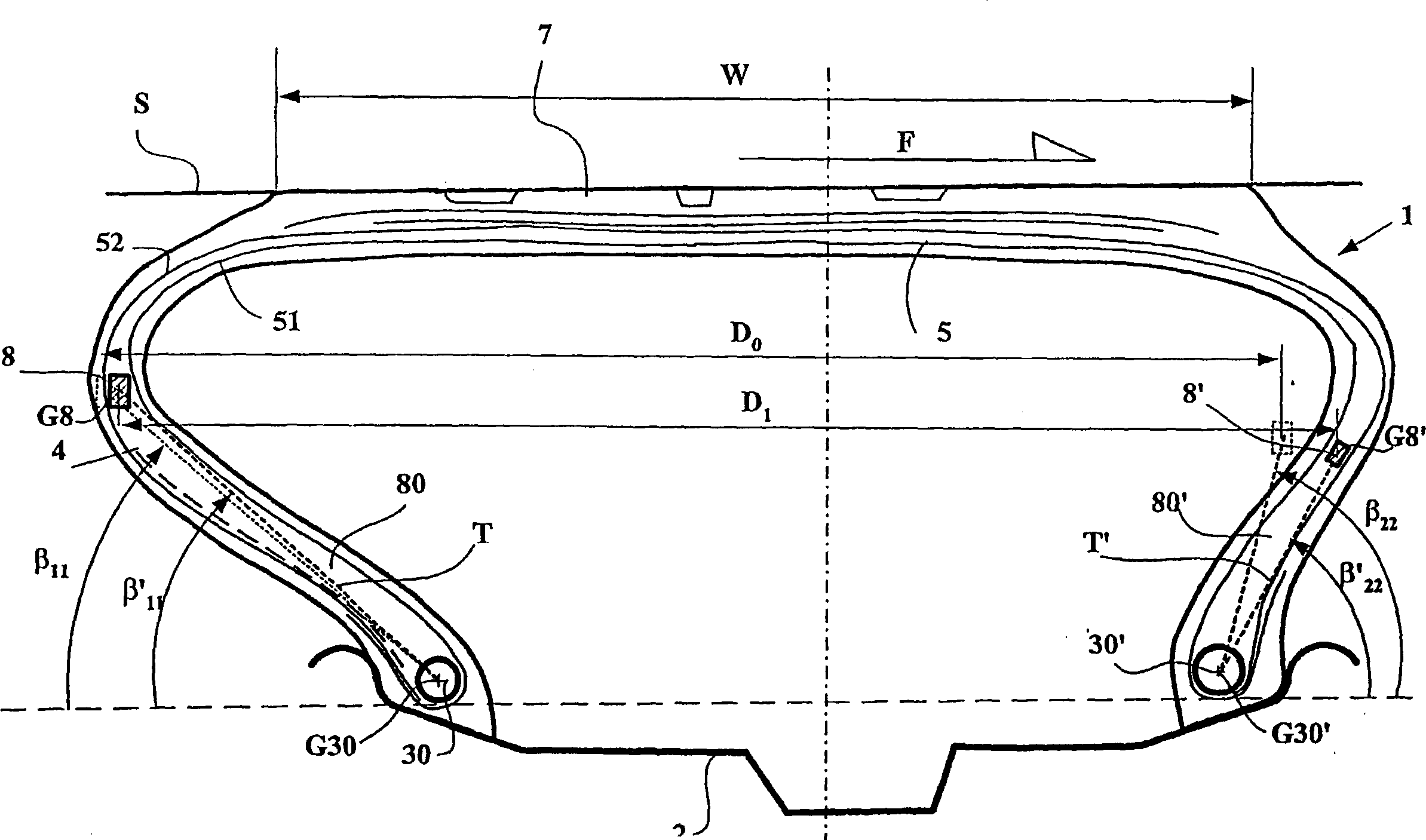

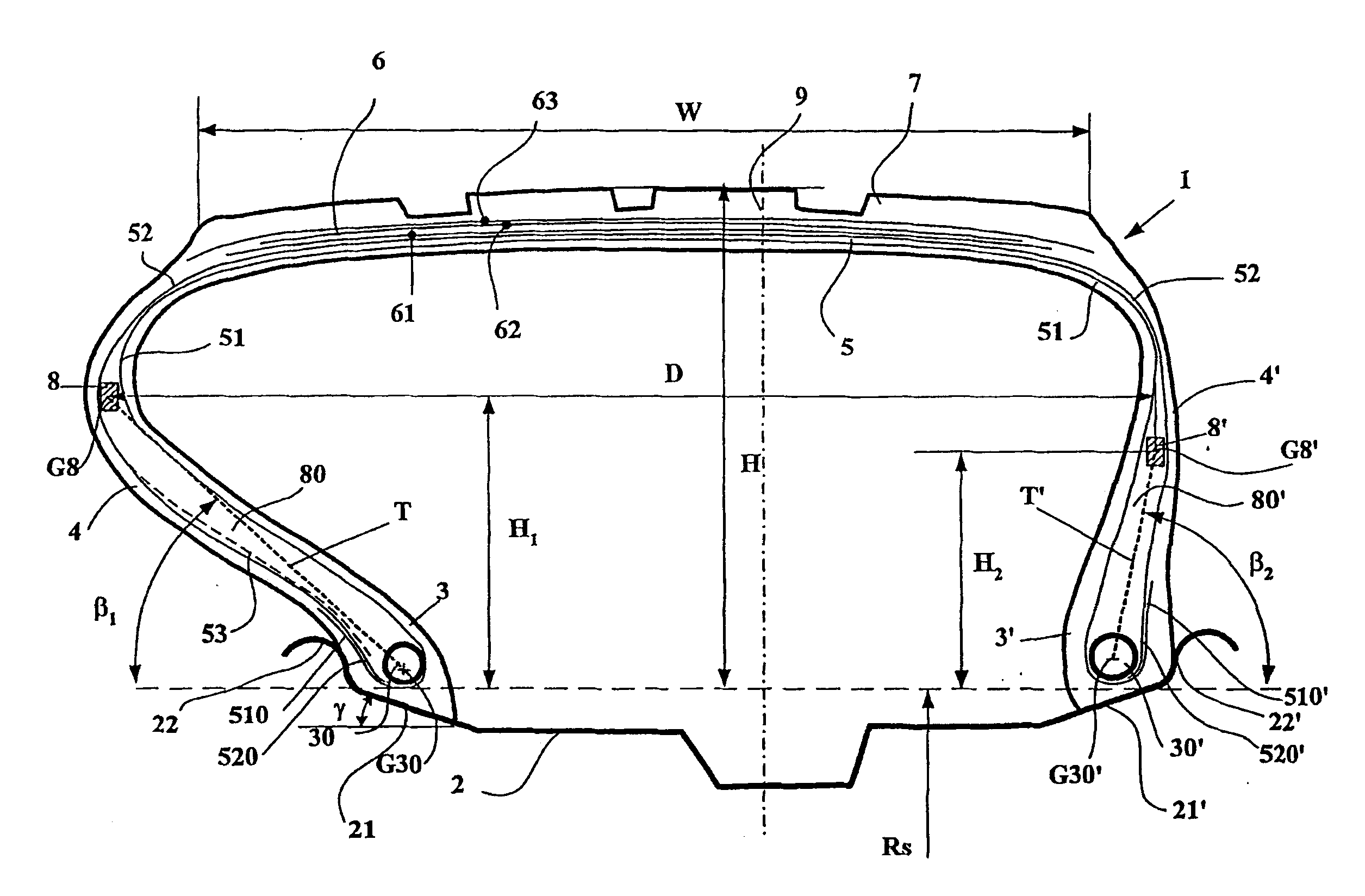

[0038] Figure 1 shows a tire 1 according to the invention mounted, inflated on a rim 2, for mounting on a passenger vehicle. When viewed in a meridian section, the tire comprises a crown 9 connected to the bead 3 and 3' of said tire 1 by two sidewalls 4 and 4', of which the first sidewall 4 is called the outer sidewall, And the second side wall 4' is called the inner side wall. The beads 3 and 3' of the tire 1 comprise, radially on the inside, an angled section open axially and radially outwards, these inclined sections are designed to come into contact with the seat 21, 21' of the rim 2, which is also inclined An angle γ, which is the same in both cases, which opens axially and radially outwardly, when the tire is mounted on its service rim, principally because of said tire pressurization, between the rim seat and the tire A mechanical compression effect is obtained between the bead. Additionally, as is known, the rim seat includes flanges 22, 22' for limiting axial movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com