Laser micro-carving method

A micro-engraving and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult control of micro-hole consistency, slow micro-hole processing speed, and difficult processing, and achieve easy and high-speed drilling , The method is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

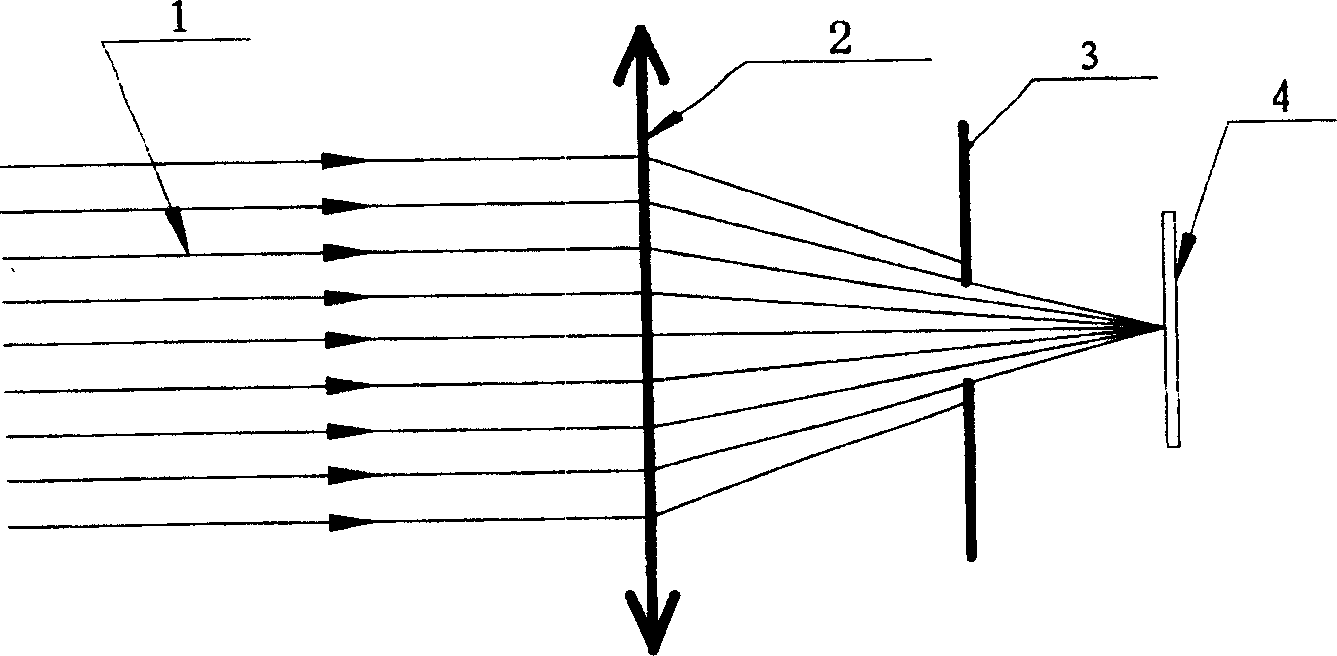

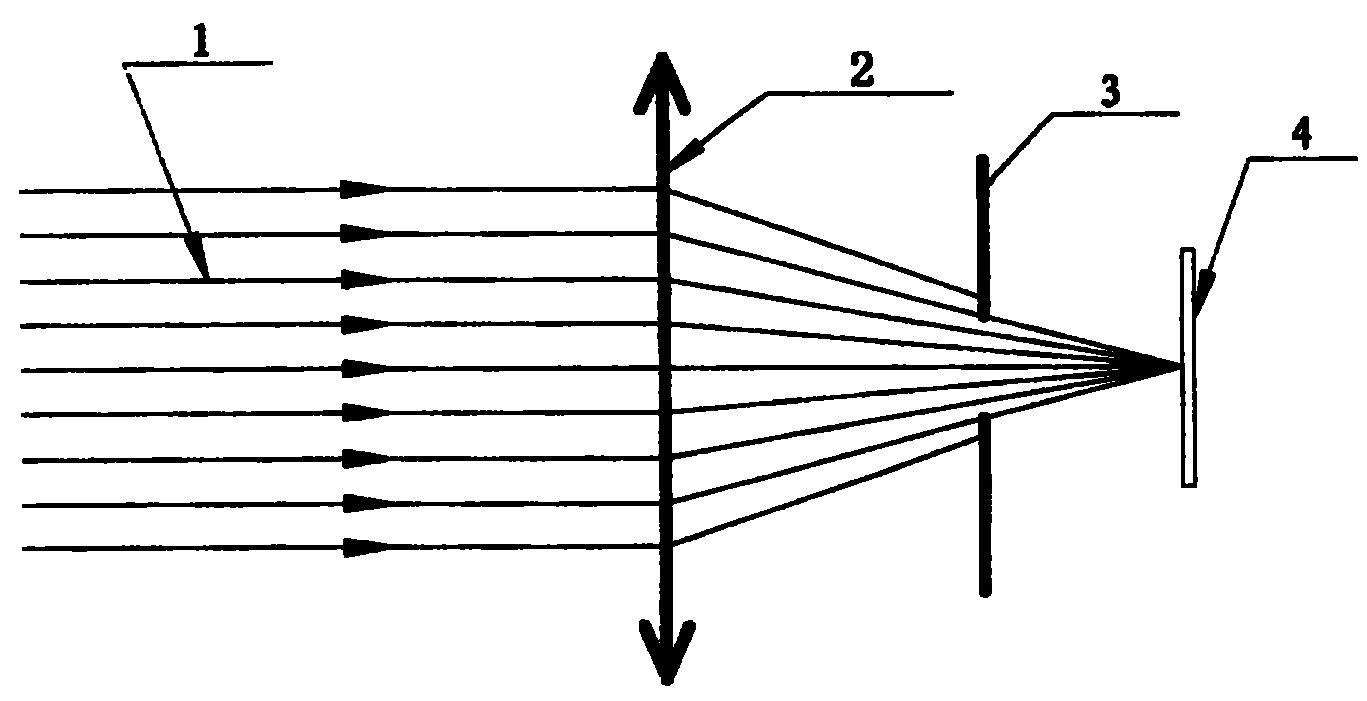

[0020] figure 1 The laser light 1 emitted by the medium carbon dioxide laser reaches the lens 2 through the optical path, and after focusing, it passes through the aperture 3 to the workpiece 4. Since the aperture on the aperture 3 is consistent with the shape of the spot to be engraved on the workpiece 4, the focused laser passes through the aperture After 3, the divergent light and unnecessary light are blocked, and the concentrated light consistent with the spot can reach the workpiece. In this way, the burn marks on the workpiece become smaller, that is, the aperture becomes smaller, and the method of the present invention can produce images far smaller than 100 micron microholes, preferably 30-100 micron round holes and / or micropits can be punched.

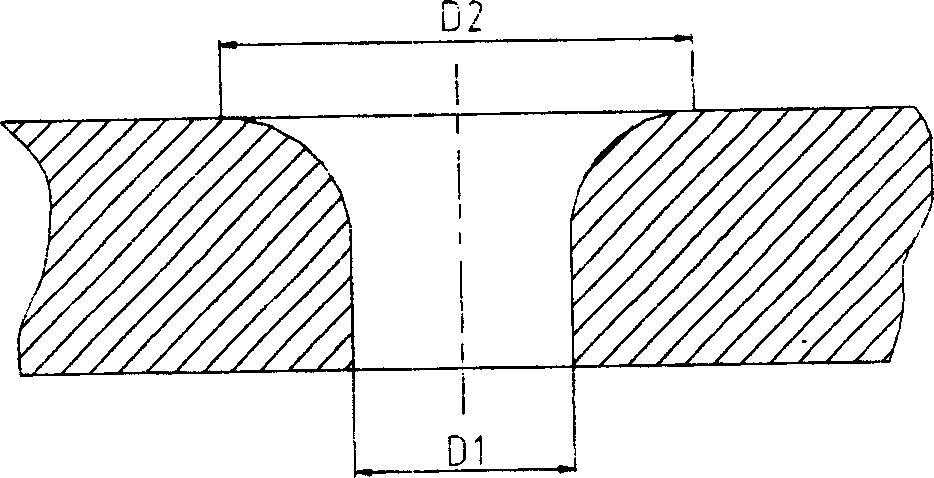

[0021] The microholes and / or micropits on the workpiece can be elliptical, the length of the long axis is 100-200 microns, and the length of the short axis is 30-80 microns. The microholes and / or micropits on the workpiece a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com