Detection structure and fabrication method for organic light emitting diode display panel

A technology of light-emitting diodes and display panels, applied to static indicators, instruments, measuring electricity, etc., can solve the problems of scrapping and waste, and achieve the effect of avoiding driving circuits and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The content and advantages of the present invention can be further understood by the following detailed description of the invention and the accompanying drawings.

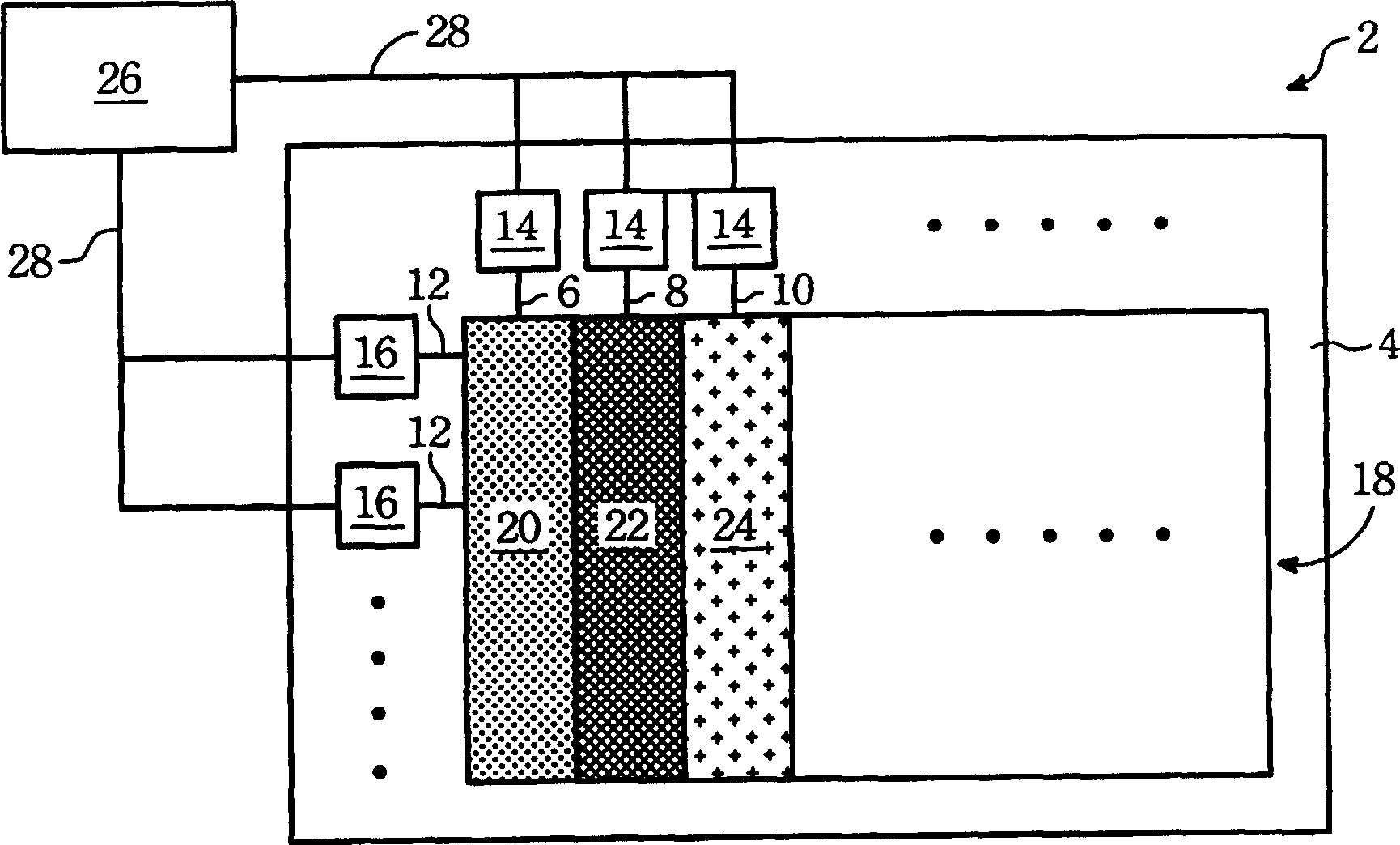

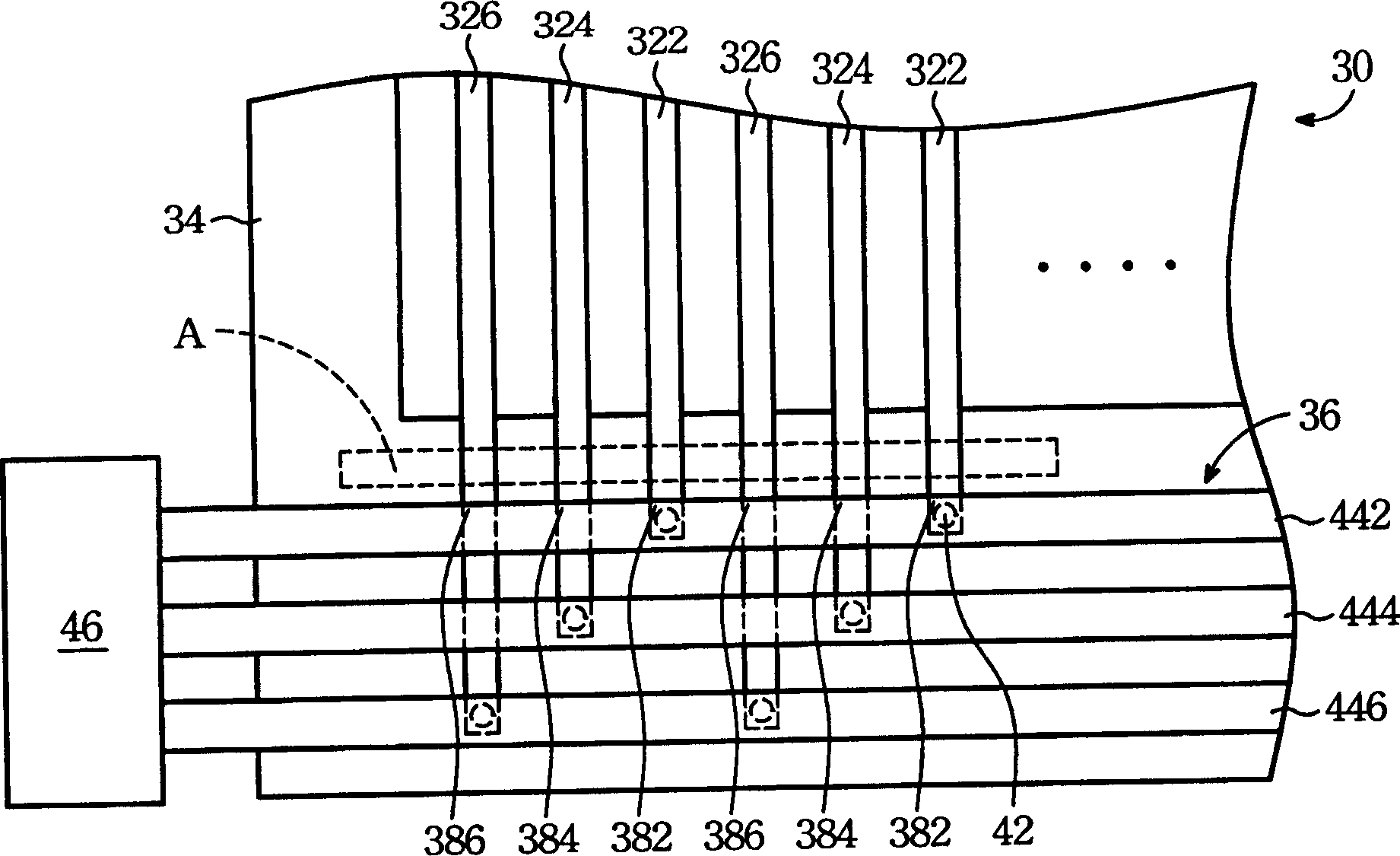

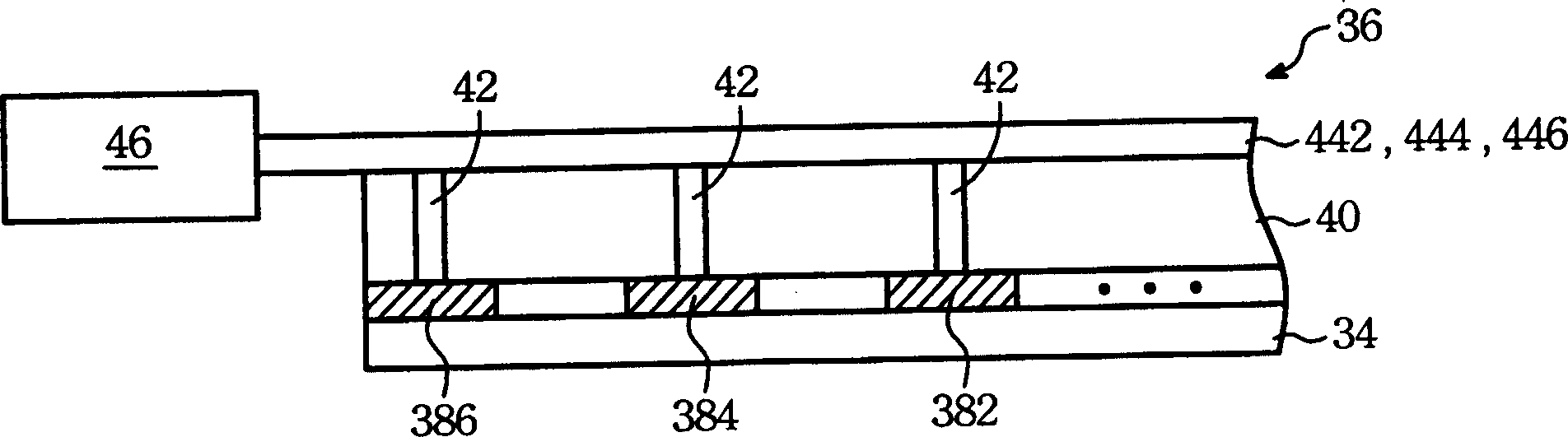

[0057] see Figure 2A , Figure 2A is a schematic diagram of the detection structure 36 of the OLED display panel 30 proposed by the present invention. The present invention provides a detection structure 36 used in the OLED display panel 30 , used for adjusting and detecting the OLED display panel 30 when the OLED display panel 30 is manufactured. The organic light emitting diode display panel 30 includes a plurality of signal wires (data lines), and the signal wires include a plurality of red, green, and blue signal wires 322, 324, 326, and the signal wires 322, 324, 326 are red, green, blue) are alternately and parallel (or approximately parallel) arranged on a substrate 34, and are respectively vertically corresponding to a plurality of red luminescent substances, a plurality of green luminescent subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com