Ammonia chloride waste water zero release treating process

A treatment process, ammonium chloride technology, applied in water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as high consumption, incomplete reaction, and inability of bacteria to survive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

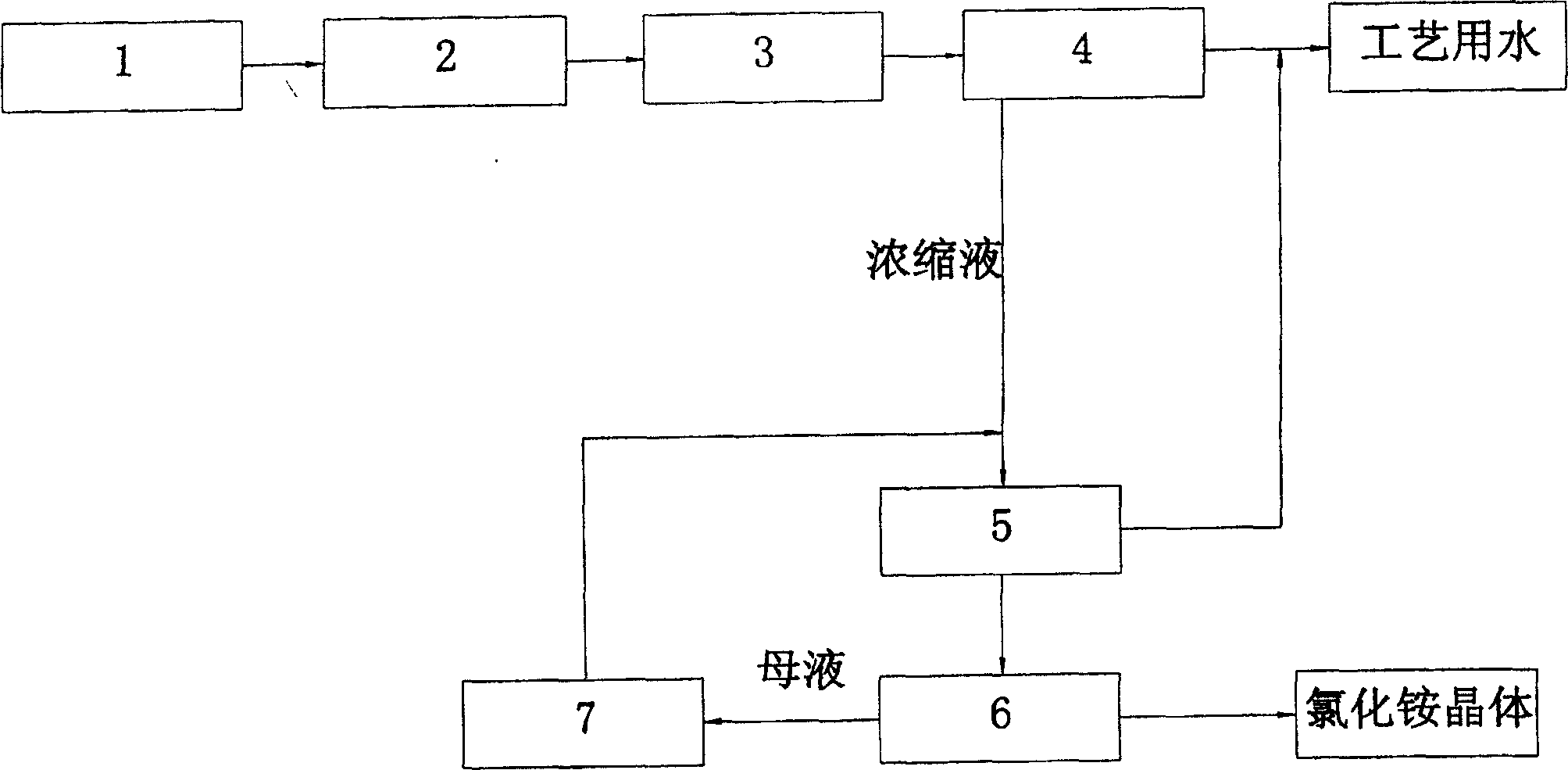

[0048] A factory has a 2-3% ammonium chloride waste liquid that needs to be recycled, and the treatment capacity is 40m 3 / h, in order to realize the zero discharge of the waste water, our recommended scheme is: first carry out the membrane concentration of the waste liquid, and then carry out the evaporation and crystallization to realize the zero discharge of the waste water.

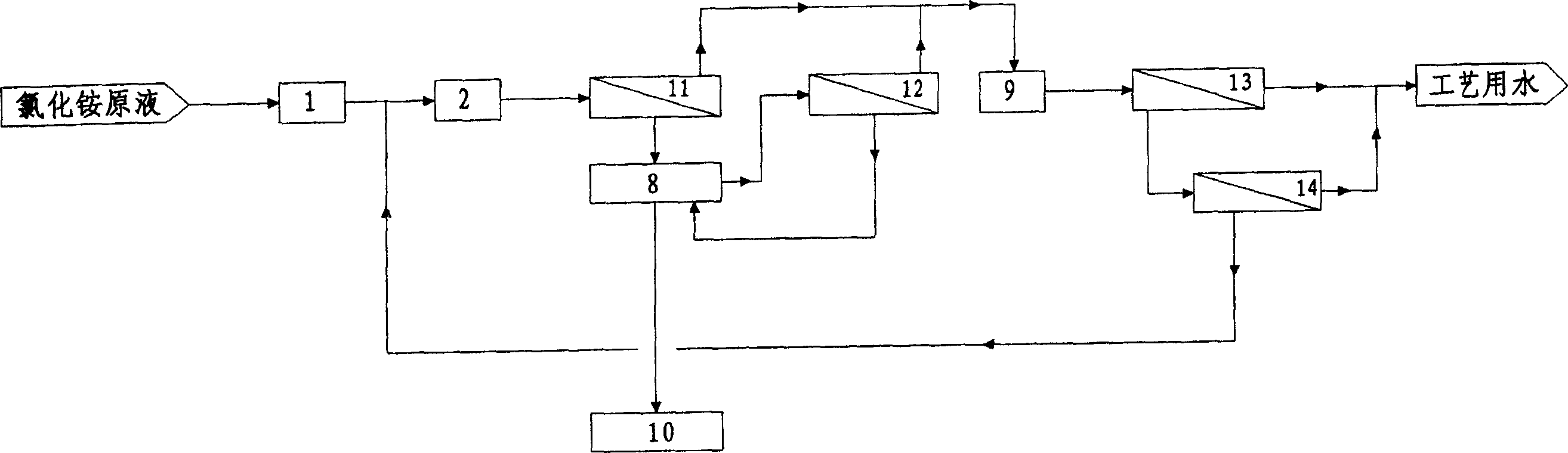

[0049] 2-3% ammonium chloride wastewater first passes through pretreatment device 1. The pretreatment scheme is continuous ultrafiltration of pipeline filter and self-cleaning filter. After pretreatment, the water quality of wastewater reaches: SDI<3, turbidity<0.1NTU .

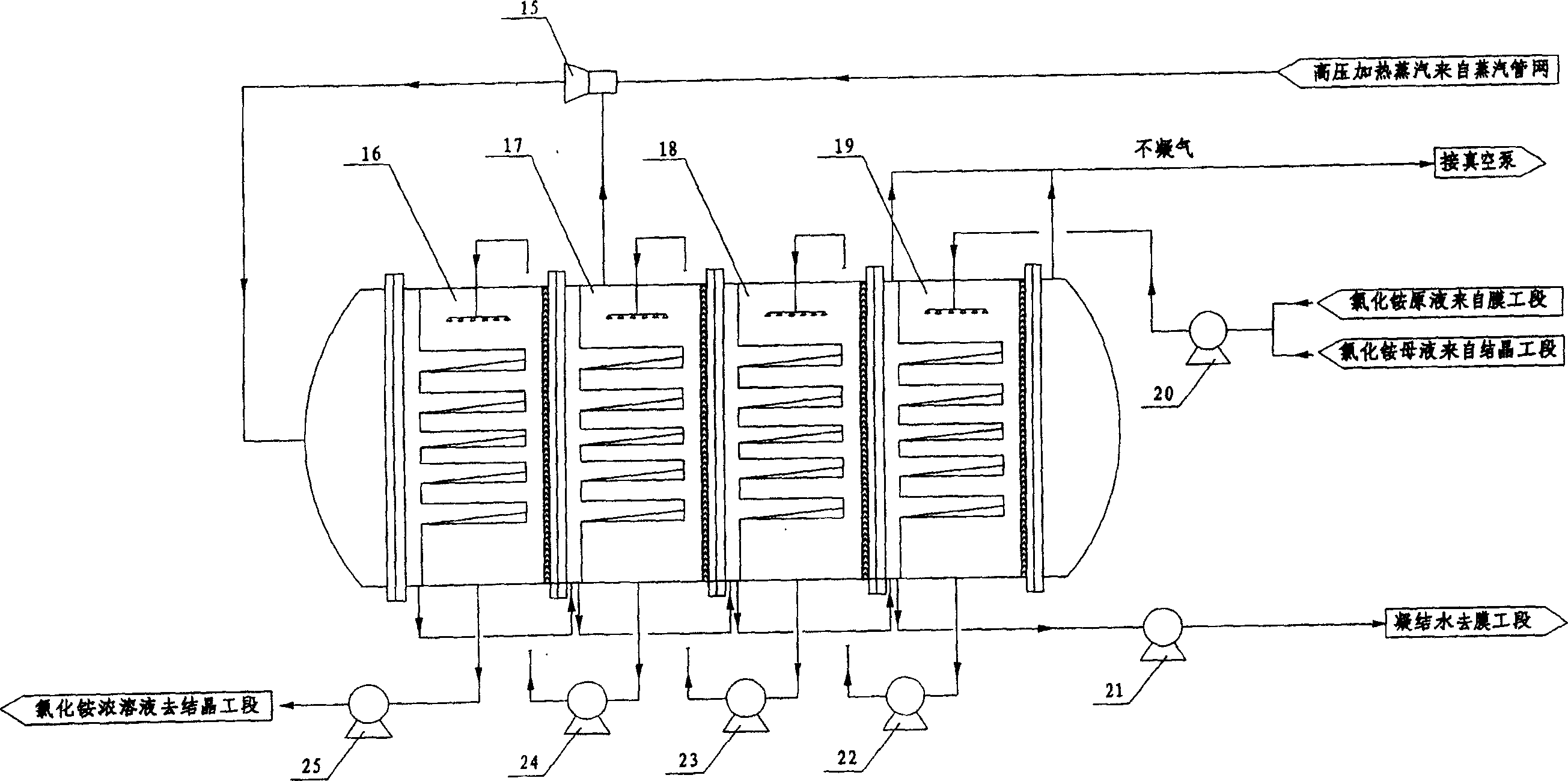

[0050] After pretreatment, the wastewater enters the first-stage reverse osmosis membrane group through the high-pressure pump 2, such as figure 2 As shown: this stage is designed into two stages, the ammonium chloride waste liquid first enters the first-stage one-stage reverse osmosis membrane group 11, and its concentrated soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com