Electric paste etching frame

A clamping frame and plasma technology, applied in the direction of circuits, electrical components, electrolysis process, etc., can solve the problems of difficult maneuver adjustment, complicated, and affecting etching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

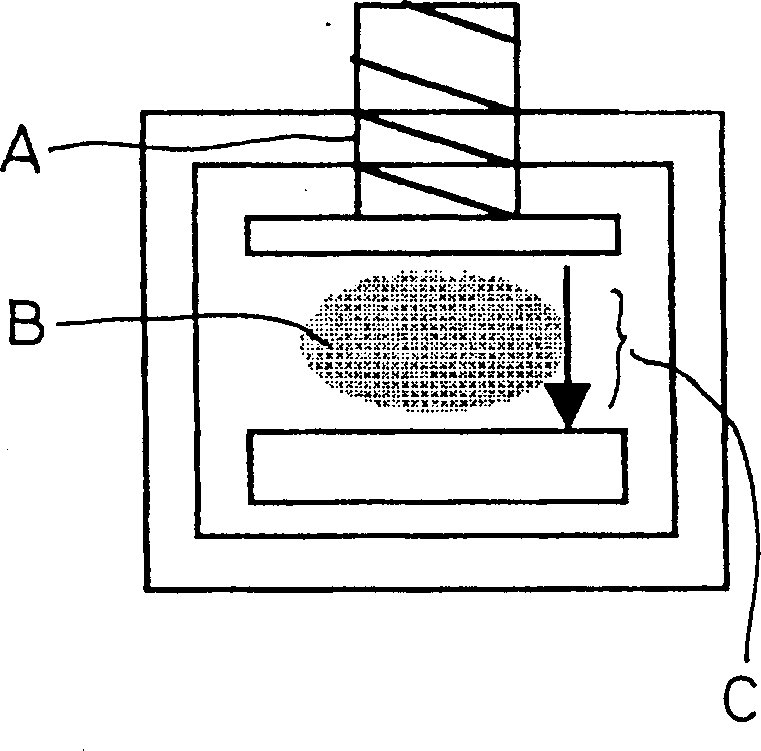

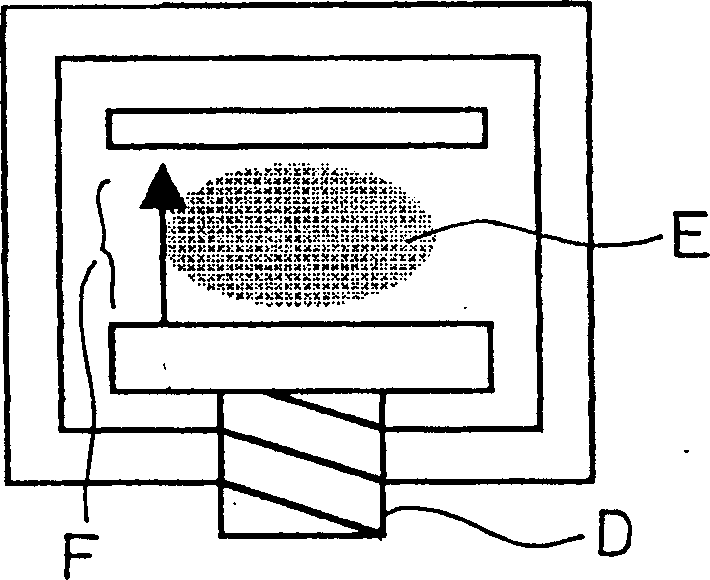

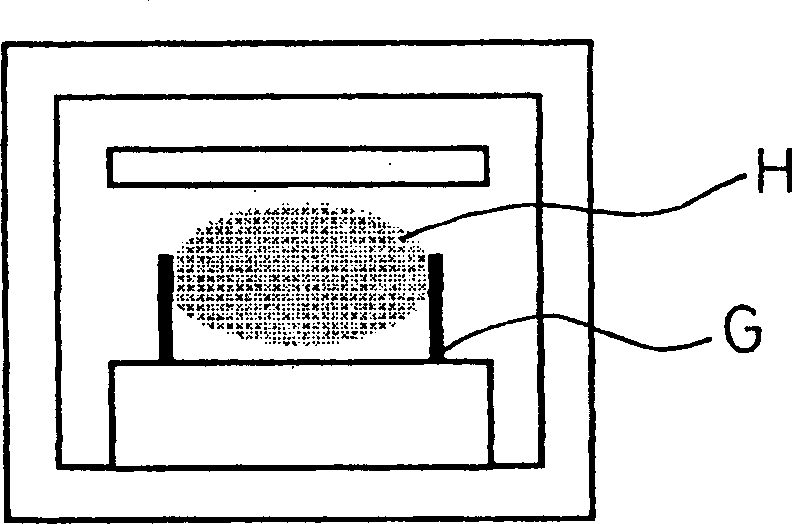

[0021] For further revealing the concrete technical content of this case, at first please refer to accompanying drawing.

[0022] As shown in FIG. 4 , basically, the clamping frame of this case is composed of a clamping frame 1 and a lifting device 2 .

[0023] Wherein, the clip frame 1 is a frame body with open ends up and down, therefore, it is formed by surrounding the frame wall 11. The frame wall 11 can be in any shape, but it is preferably square or rectangular, that is, it can be formed by Surrounded by frame walls 11 vertically arranged on four sides, and its bottom has a lifting connection device 12, which can be like lugs and holes are provided, but it is not limited to this.

[0024] The material of this frame wall 11 can usually be fine ceramics, in order to be replaceable, so it can be connected in a single piece, and at this time, the lifting connection device can connect a bottom frame 13, and the size of the bottom frame 13 Corresponding to the frame wall 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com