Device and method for controlling NOx during burning

A nitrogen oxide, combustion technology, applied in combustion methods, chemical instruments and methods, combustion products treatment, etc., can solve the problems of unadjustable, unpredictable chlorine content in urban solid waste streams, etc., to save usage, reduce Long-term environmental problems, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

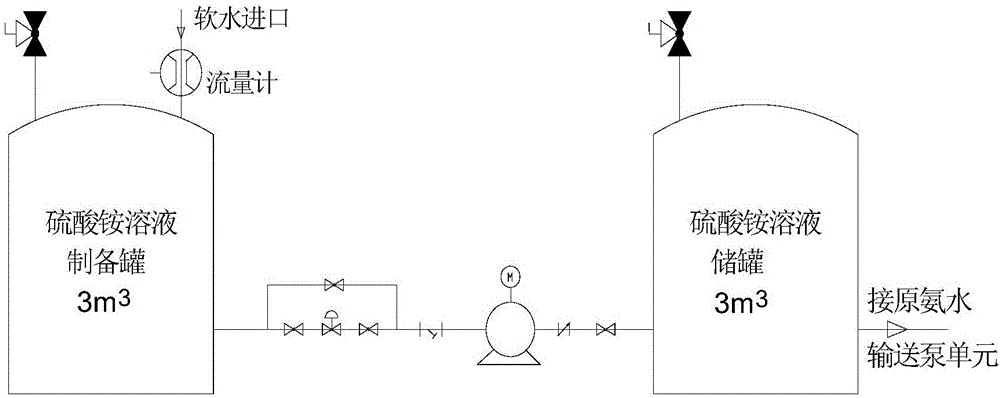

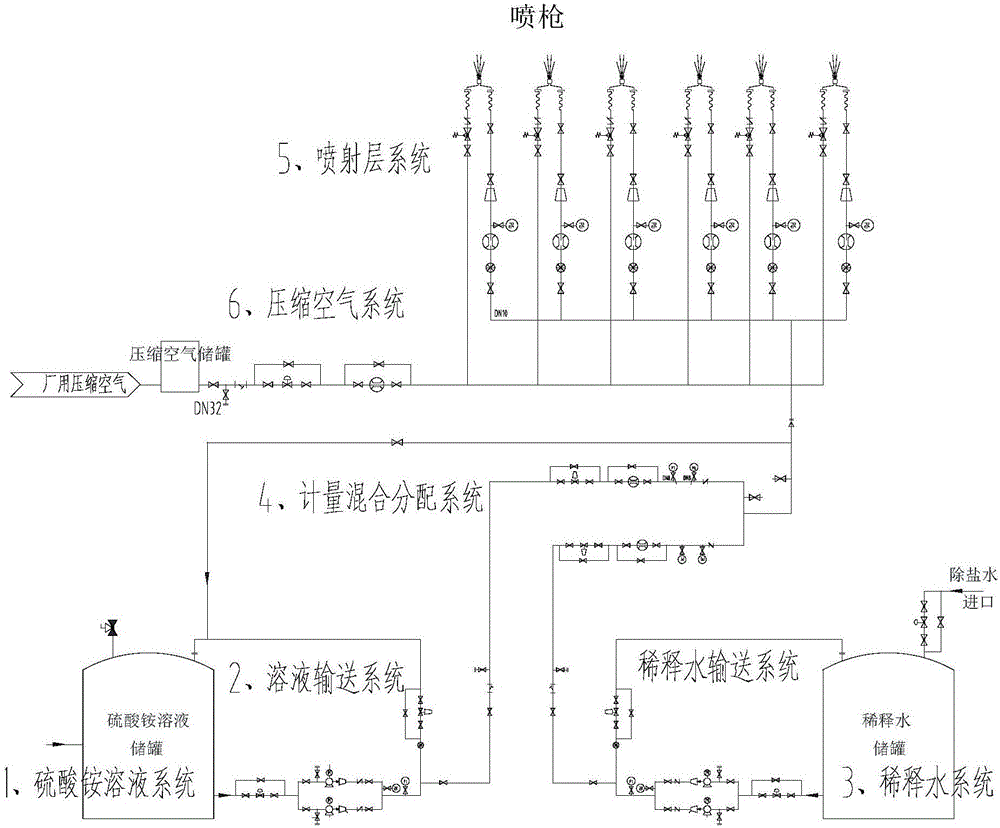

[0047] Below, refer to figure 1 and figure 2 The device for controlling nitrogen oxides of the present invention is described in detail, wherein, figure 1 It is a structural schematic diagram of the ammonium sulfate system described in the device for controlling nitrogen oxides of the present invention; figure 2 It is a structural schematic diagram of the device for controlling nitrogen oxides in the present invention.

[0048] In order to solve the problems in the prior art, the present invention provides a combustion method and device for controlling nitrogen oxides. x content, prepare a certain concentration of ammonium sulfate solution, spray the ammonium sulfate solution into the incinerator through the SNCR system, and the ammonium sulfate will be completely decomposed into NH at a temperature above 513°C 3 and SO 2 , where NH 3 Ions and NO in combustion flue gas x A reduction reaction occurs to form N 2 , so as to reduce NO in combustion flue gas x the goal of...

Embodiment 2

[0077] An embodiment of the present invention provides a control method based on the device described in Embodiment 1, the method comprising:

[0078] Step S1: configuring the ammonium sulfate salt into an ammonium sulfate salt solution, and transporting the ammonium sulfate salt solution to the metering mixing distribution system;

[0079] Step S2: adjusting the ammonium sulfate salt solution in the metering mixing distribution system to obtain the ammonium sulfate salt solution of the target concentration;

[0080] Step S3: transporting the ammonium sulfate salt solution with a target concentration to the spray layer system and spraying it into the incinerator through the spray layer system to reduce the nitrogen oxides produced by combustion.

[0081] Wherein, the concentration of the ammonium sulfate salt solution in the step S1 is 40wt% or above.

[0082] Wherein, the ammonium sulfate salt includes ammonium sulfate and ammonium bisulfate.

[0083] In the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com