Front wheel fork structure for saddle type vehicle

A vehicle and saddle type technology, applied in the field of front fork structure, can solve the problems of complex structure and troublesome front fork forming, and achieve the effect of large cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

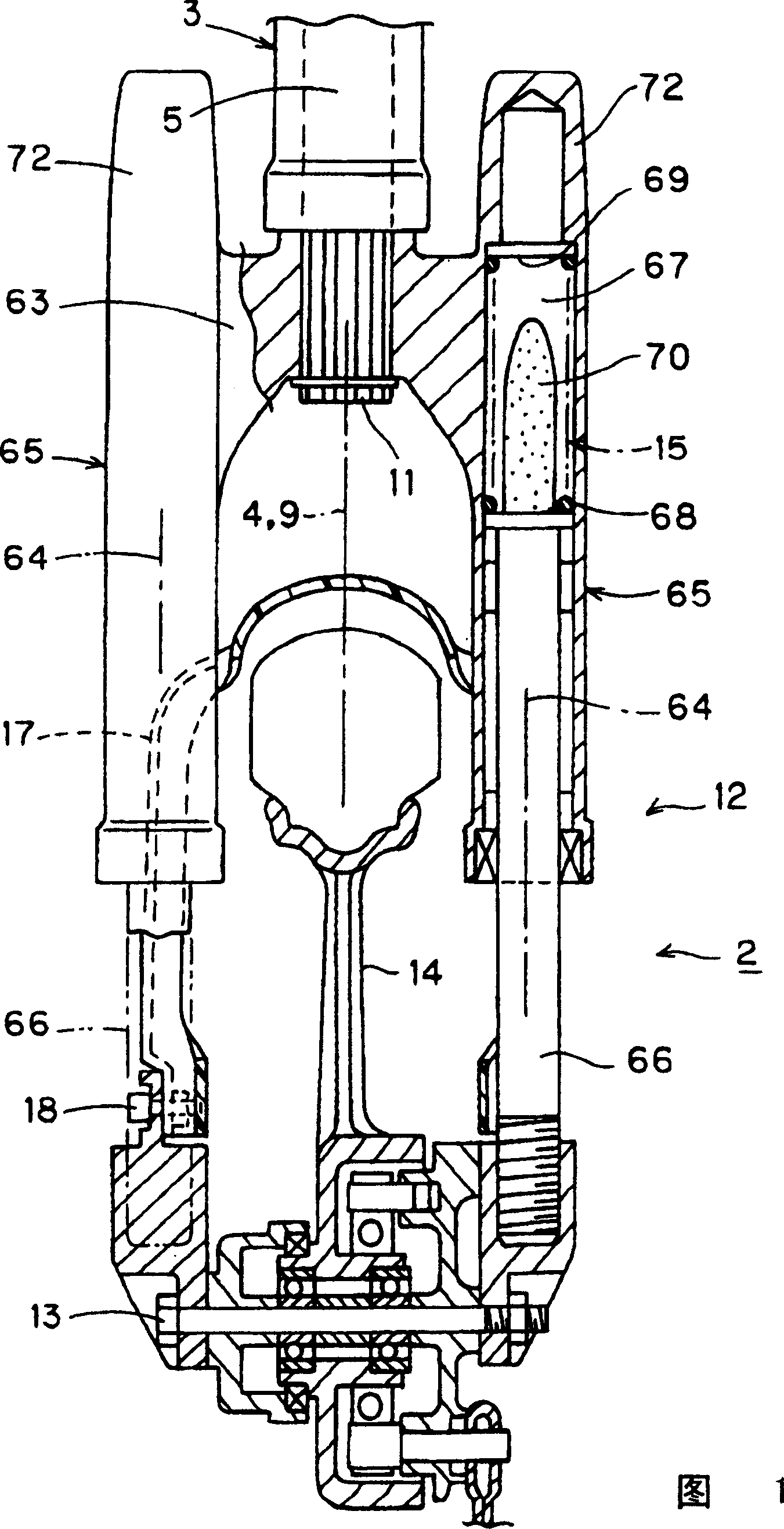

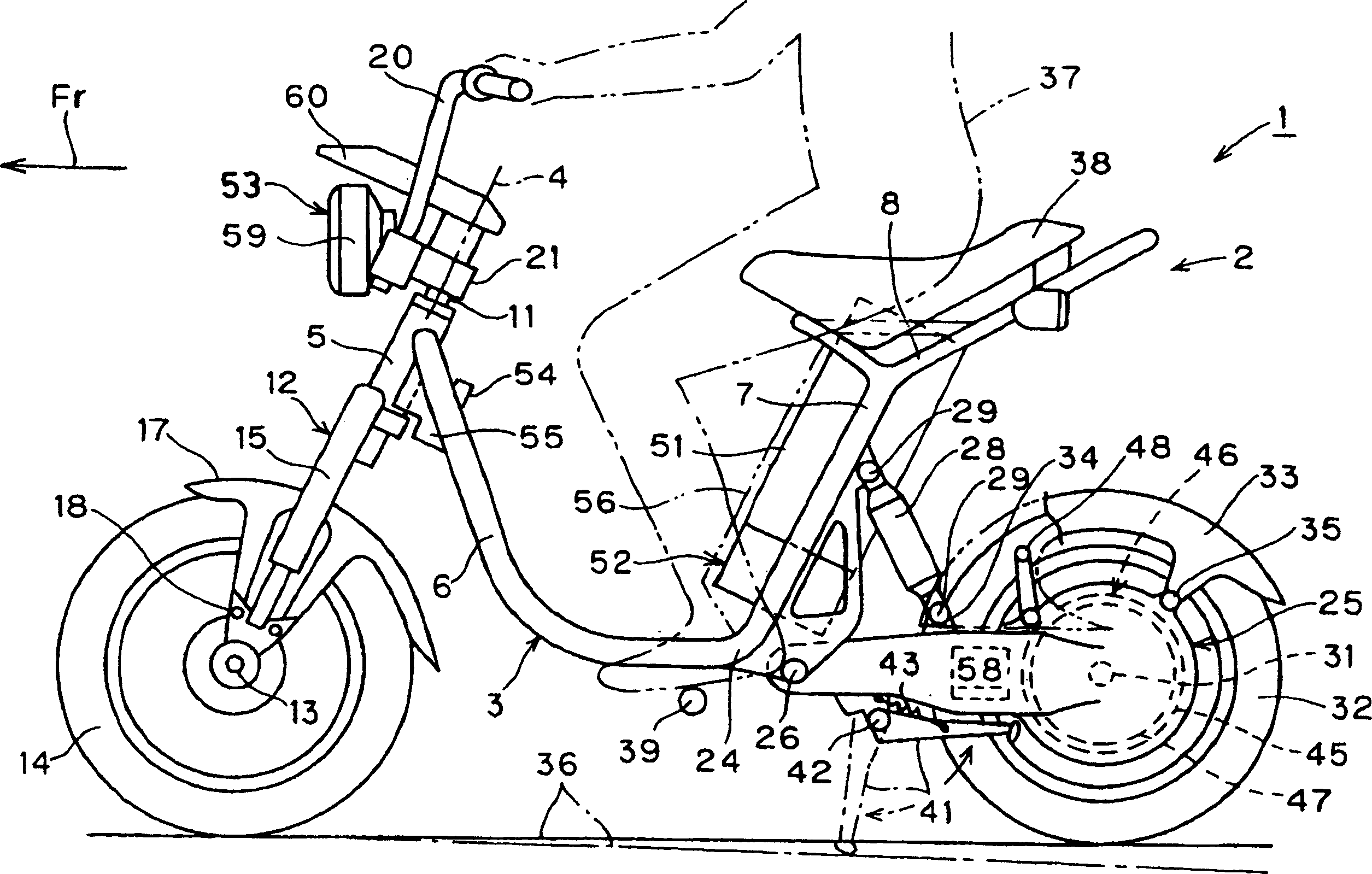

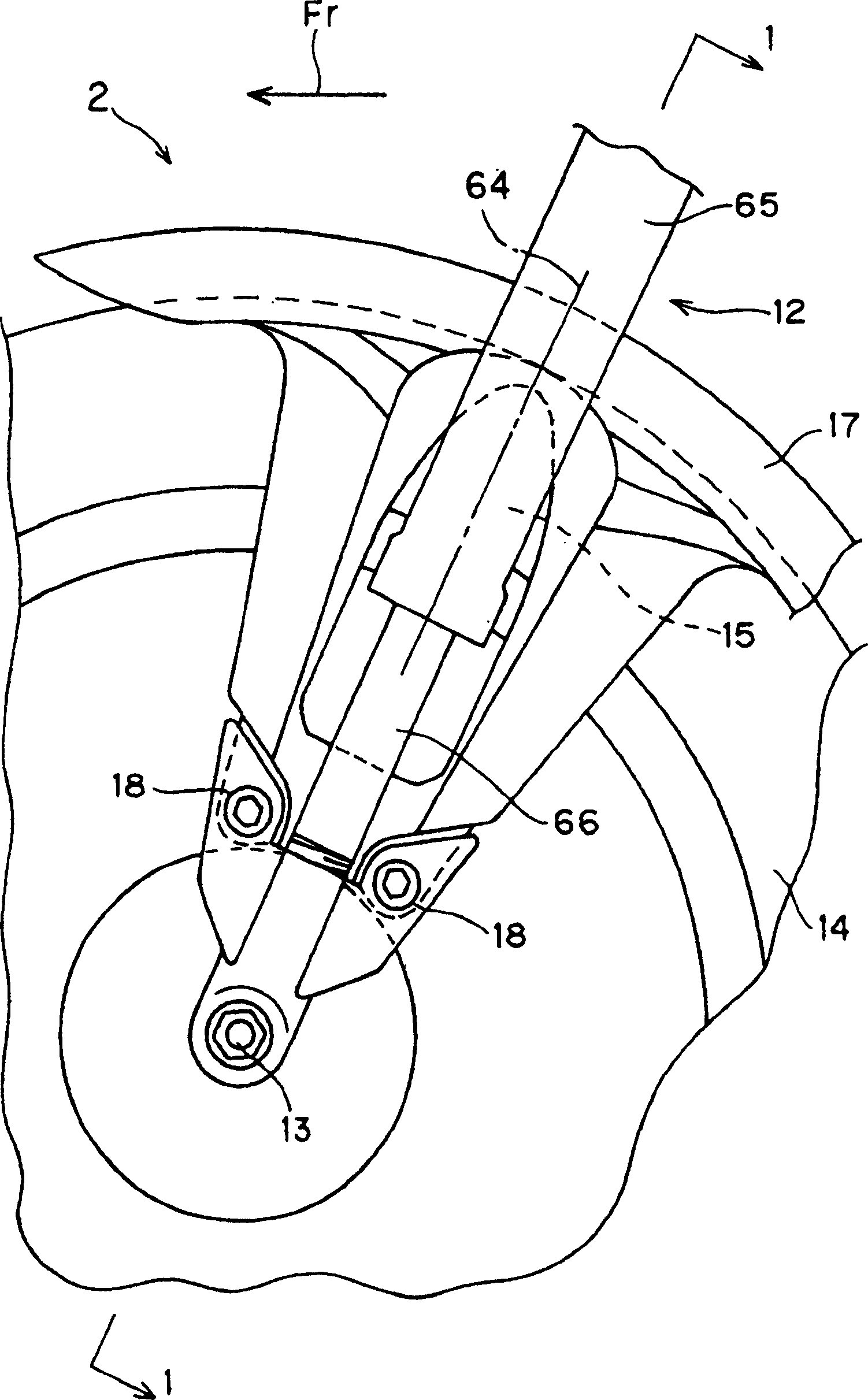

[0019] 1 to 3 show a first embodiment of the present invention.

[0020] figure 2 In the figure, reference numeral 1 is a saddle-riding vehicle, and an electric two-wheeled vehicle (motorcycle) is taken as an example to specifically show it. The arrow Fr indicates the front of the vehicle 1, and the so-called left and right referred to below refers to the width direction of the vehicle body 2 of the vehicle 1 facing the above-mentioned front.

[0021] The vehicle body frame 3 of the above-mentioned vehicle body 2 has: a front pipe 5 constituting its front upper end and extending in a downward direction with the axis 4 in the longitudinal direction; 6; a pair of left and right rear struts 7, 7 protruding from the protruding ends of the lower tubes 6, 6 to the rear; an upper frame 8 that combines the protruding ends of these rear struts 7, 7, The vehicle body frame 3 is formed bilaterally symmetrically with respect to an imaginary vertical plane passing through the vehicle bo...

no. 2 Embodiment approach

[0049] Figure 4 The second embodiment of the present invention is shown.

[0050] According to this second embodiment, at least the respective upper portions of the spring 68 and a part of the moving track 74 of the impact limiter 70 are arranged in the space 67 inside the upper end portion 72 of each of the upper pipes 65 .

[0051] Therefore, the upper end portion 72 of each upper tube 65 can be used for disposing the spring 68 and the impact limiter 70, which does not increase the vertical dimension of the front fork 12, and can further improve the shock absorbing function.

[0052] The upper end portion 72 of each of the above-mentioned upper pipes 65 also has: a tubular base portion 72a that is integrally formed with each side portion of the above-mentioned bracket 63 and whose upper end portion protrudes upwards from the upper surface of each side portion of the above-mentioned bracket 63; 72b, a cap 72c detachably attached to the upper end of the base 72a, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com