Multi-cross sectional fluid path condenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

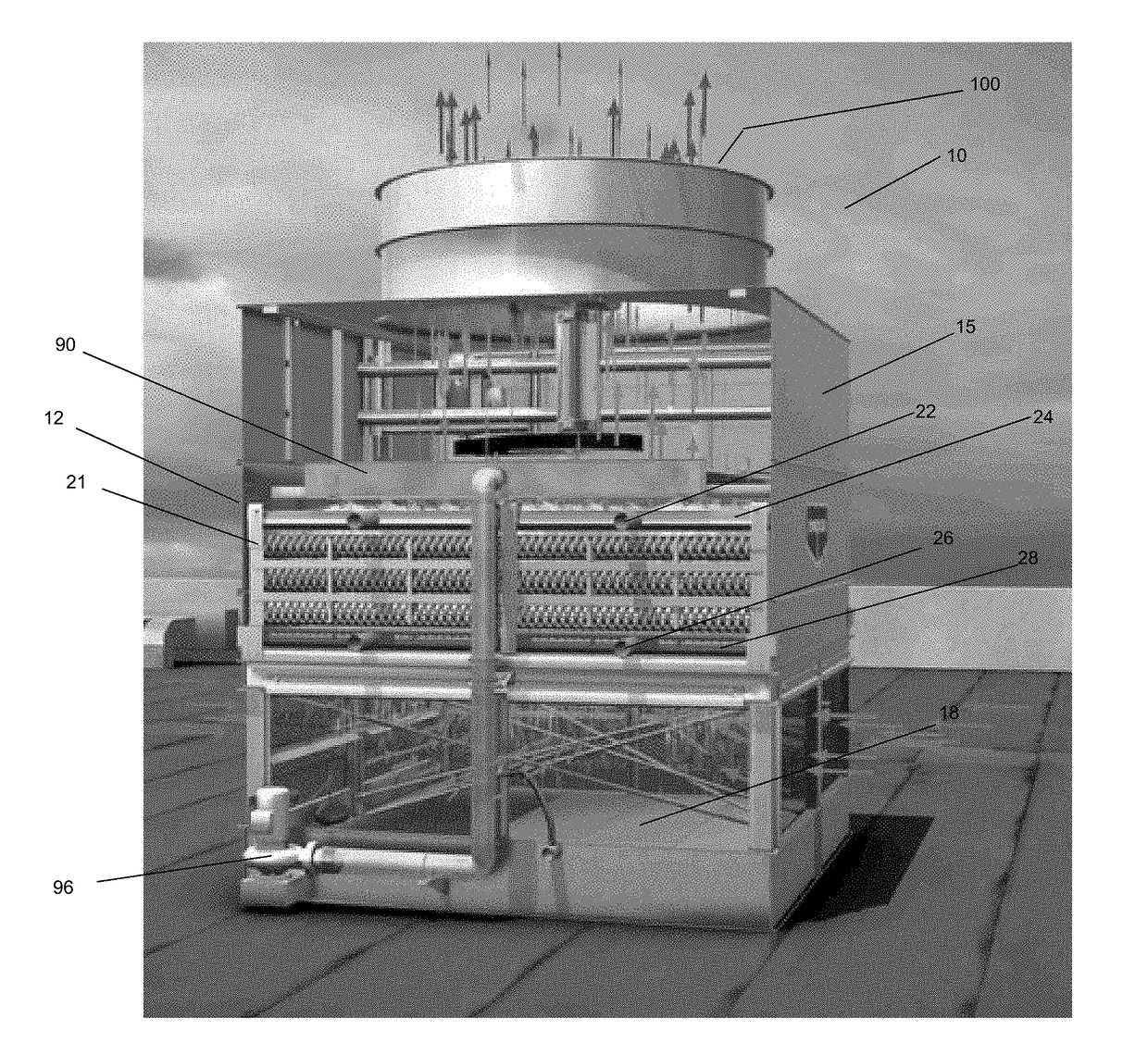

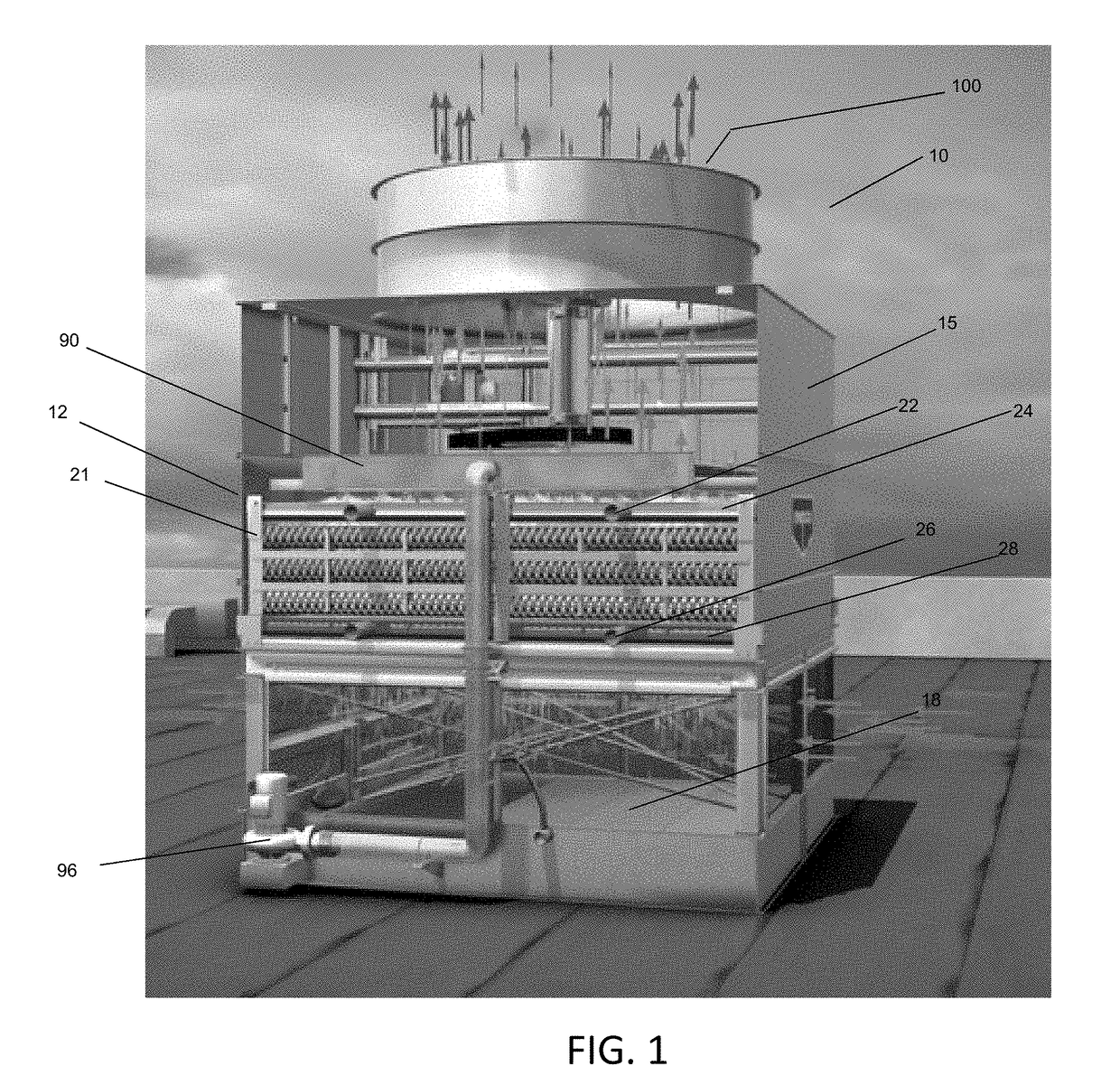

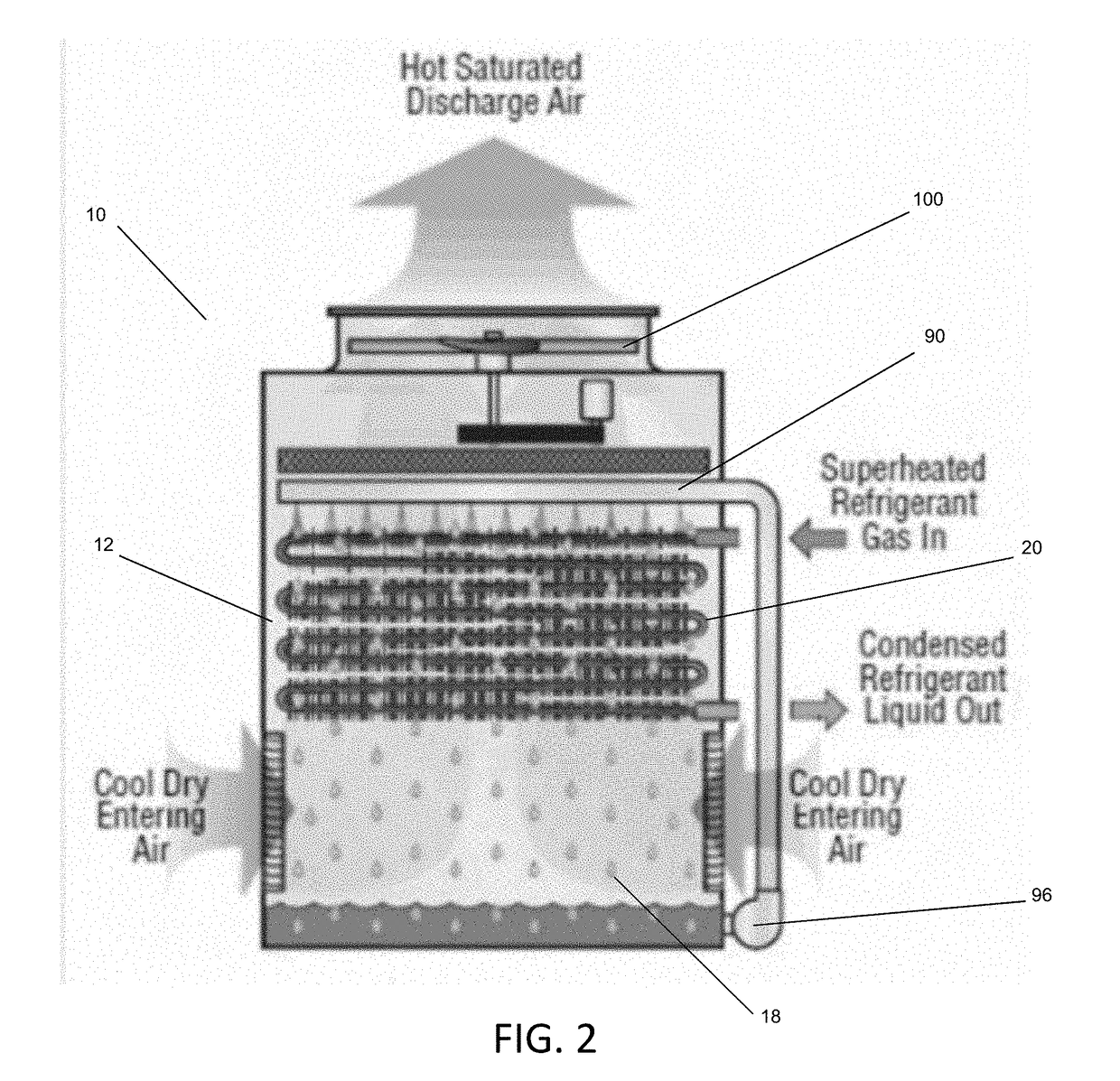

[0019]This invention relates particularly to condenser coil bundles used in refrigerant condensers, and particularly (although not exclusively) in evaporative refrigerant condensers 10 of the type shown in FIGS. 1 and 2 configured to indirectly transfer heat between a superheated refrigerant and ambient air, operative in a wet mode or a dry mode as described below depending on ambient atmospheric conditions, such as temperature, humidity and pressure.

[0020]The apparatus 10 includes a fan 100 for causing air to flow through the apparatus, and as shown schematically in FIG. 1, sitting atop housing 15. At normal ambient atmospheric conditions where freezing of the cooling liquid, typically water, is not of concern, air is drawn into the plenum 18 of the apparatus via air passages at the bottom of the unit through the open air intake dampers, and enters the evaporative heat transfer section 12 where heat transfer takes place involving the distribution of water from a water distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com